GE Security FHSD700C Series Product Guide

2.2 Alarms and Trace Mode

The default settings of the four alarm states (Alert, Action, Fire1 and Fire2) and Trace are shown in the

following table. The Trace threshold is only applicable to detectors FHSD724DC to FHSD7215DC,

which have a rotary valve.

Table 2-1: Default Behavior of Alarm States and Trace Mode

Level Latched / Unlatched Threshold Delay Beacon Pulse (On:Off) Sounder

Trace Latched 0.03% obs/m 3 secs - Continuous

Alert Latched 0.04% obs/m 3 secs 0.5 secs : 2 secs Continuous

Action Latched 0.06% obs/m 3 secs 0.5 secs : 1 sec Continuous

Fire1 Latched 0.08% obs/m 3 secs 0.5 secs : 0.5 secs Continuous

Fire2 Latched 0.1% obs/m 3 secs Continuous Continuous

Trace parameters apply when the rotary valve is in the Overall position and all sectors are being

monitored. If latched, the Trace indicator will remain illuminated after the initiating event has ceased. It

does NOT mean that the unit will continue indefinitely in Trace (scan) mode. The system will only

continue in Trace mode if the detected smoke level is above the Trace threshold after scanning. The

Alert relay may be programmed to be activated by the Trace threshold. Its action will then follow that of

the Trace indicator.

If any alarms are unlatched, all resultant actions (relay contacts, display panel indicators, sounder and

beacon) will clear if and when the triggering event ceases. If it is latched, all the warning mechanisms

are maintained until action is taken by the user (please see Detector Display Panel on page 3). These

alarm states are global and will be set depending on the smoke density being measured, regardless of

which sector is being sampled. Once in Trace mode, each sector has an alarm indicator associated with

it. These individual sector alarms pulse progressively, depending on the degree of alarm status, in the

same way as the Beacon (please see Default Behavior of Alarm States and Trace Mode on page 3).

2.3 Detector Display Panel

All FHSD700C detectors (except for the FHSD720C and FHSD721C) can have a full display panel or a

blank panel fitted to the main system. The FHSD720C and FHSD721C have no display but can be

connected to a remote display unit via RS485 communications from the Main I/O module. The display

panel is used for annunciating the detector status and smoke levels, and can also be used to configure

the detector.

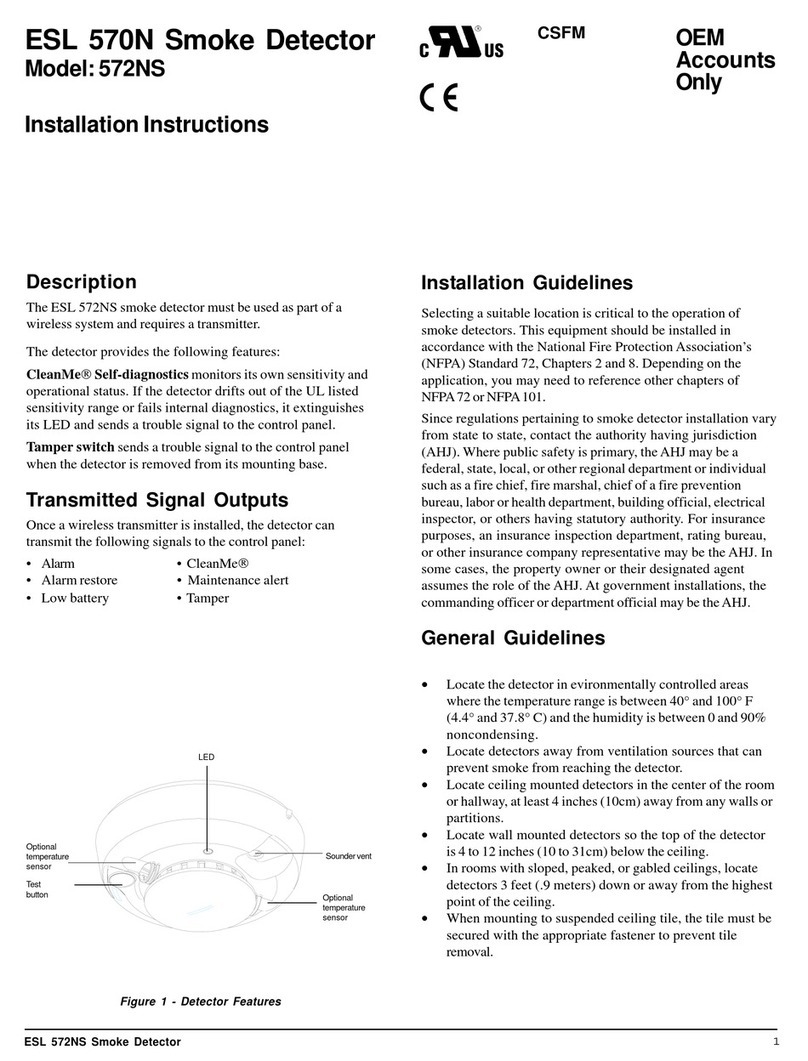

The display consists of a range of configuration and control buttons (Item 1 in Figure 2-1) and LEDs to

indicate Alarms, Faults, Power, Reset and other operational status (Items 5 and 6 in Figure 2-1). When

configuring the detector via the display panel, some of these configuration and control buttons will have

a dual function to allow the user to enter parameter values, scroll through configuration items, or enter

an Access Code. Alternate functions are indicated by LEDs located above the buttons (Item 3 in Figure

2-1) and are activated when the associated button can be used for the alternative function.

More information about button functionality, Access Codes and how to setup the detector with the Main

Menu can be found in Setup and Button Functionality on page 18. A flowchart illustrating how to

navigate through the display panel can be found in Appendix A Display Panel Navigation on page 35.

www.gesecurity.net 3