GE POWERMASTER AKD-5 User manual

Other GE Switch manuals

GE

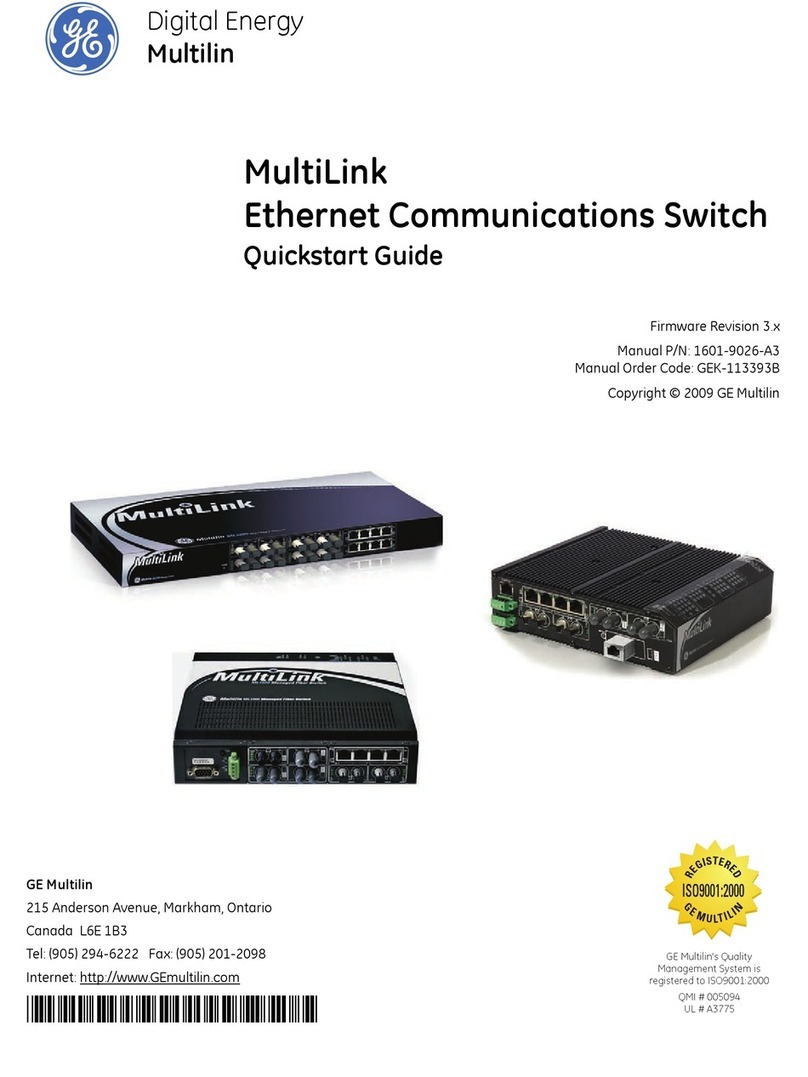

GE MultiLink ML1200 User manual

GE

GE GLX+Q 1 1COM 16A 2M AST IR User manual

GE

GE CWLSWDMBWF1 User manual

GE

GE C-Start User manual

GE

GE RAK204 User manual

GE

GE MultiLink ML600 User manual

GE

GE USB 2.0 7-Port Hub HO97916 User manual

GE

GE 97845 User manual

GE

GE MultiLink User manual

GE

GE ABB ReliaGear LV SG User manual