SecoGear Medium-voltage Switchgear Application and Technical Guide DET-882

iv ©2017 General Electric All Rights Reserved

Protective Scheme Selection................................................................................................................................................................................................40

Optional Equipment Selection.............................................................................................................................................................................................41

Protection...................................................................................................................................................................................................................................41

Indication...................................................................................................................................................................................................................................41

Control.........................................................................................................................................................................................................................................42

Dual-Source Incoming Lines (DSIL).........................................................................................................................................................................................43

Basic Equipment Selection....................................................................................................................................................................................................43

Optional Equipment Selection.............................................................................................................................................................................................43

Protection...................................................................................................................................................................................................................................43

Indication...................................................................................................................................................................................................................................43

Control.........................................................................................................................................................................................................................................43

Location of Optional Devices...........................................................................................................................................................................................43

Bus Ties (BT).........................................................................................................................................................................................................................................44

Basic Equipment Selection....................................................................................................................................................................................................44

Optional Equipment Selection.............................................................................................................................................................................................44

Protection...................................................................................................................................................................................................................................44

Indication...................................................................................................................................................................................................................................45

Control.........................................................................................................................................................................................................................................45

Bus Entrances (BE)...........................................................................................................................................................................................................................46

Basic Equipment Selection....................................................................................................................................................................................................46

Optional Indication Selection...............................................................................................................................................................................................46

Induction Motor Feeders (IMF)...................................................................................................................................................................................................46

Protective Scheme Selection................................................................................................................................................................................................46

Optional Equipment Selection (for IMFE, IMF1, IMF2)..............................................................................................................................................47

Protection...................................................................................................................................................................................................................................47

Indication...................................................................................................................................................................................................................................47

Control.........................................................................................................................................................................................................................................47

Location of Optional Devices...........................................................................................................................................................................................47

Reduced Voltage Starting............................................................................................................................................................................................................49

Synchronous Motor Feeders (SMF).........................................................................................................................................................................................49

Protective Scheme Selection................................................................................................................................................................................................49

Optional Equipment Selection (for SMF1 and SMF2)...............................................................................................................................................50

Protection...................................................................................................................................................................................................................................50

Excitation....................................................................................................................................................................................................................................50

Indication...................................................................................................................................................................................................................................50

Control.........................................................................................................................................................................................................................................50

Location of Optional Devices...........................................................................................................................................................................................50

Standard Breaker and Auxiliary Configurations..............................................................................................................................................................52

Standard Tie Breaker and Auxiliary Configurations......................................................................................................................................................53

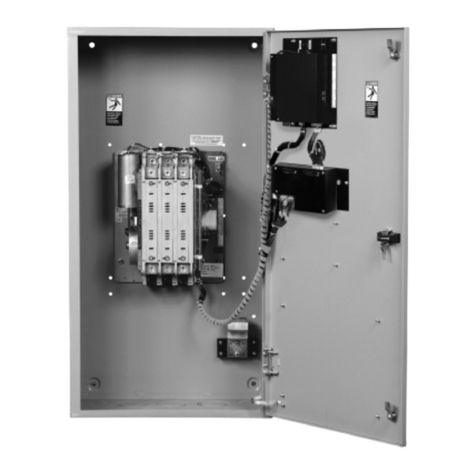

SECTION 6. Standard SecoGear Construction, Features, and Installation.............................................................................. 55

Documentation.................................................................................................................................................................................................................................55

Construction.......................................................................................................................................................................................................................................55

Indoor Equipment......................................................................................................................................................................................................................55

Hardware........................................................................................................................................................................................................................................55

Breaker Compartments..........................................................................................................................................................................................................55

Visual Breaker Position Indication................................................................................................................................................................................56

Auxiliary Compartments........................................................................................................................................................................................................56

Compartment Doors............................................................................................................................................................................................................56

Safety Interlocks.........................................................................................................................................................................................................................57

Secondary Disconnect Interlocking.............................................................................................................................................................................57

Safety Key Lock Provisions...............................................................................................................................................................................................58

Padlock for Open/Close Pushbutton (Optional).....................................................................................................................................................59

Main Bus.........................................................................................................................................................................................................................................59

Secondary Control.....................................................................................................................................................................................................................59

Door-mounted Devices......................................................................................................................................................................................................59

Equipment-mounted Devices.........................................................................................................................................................................................59