5

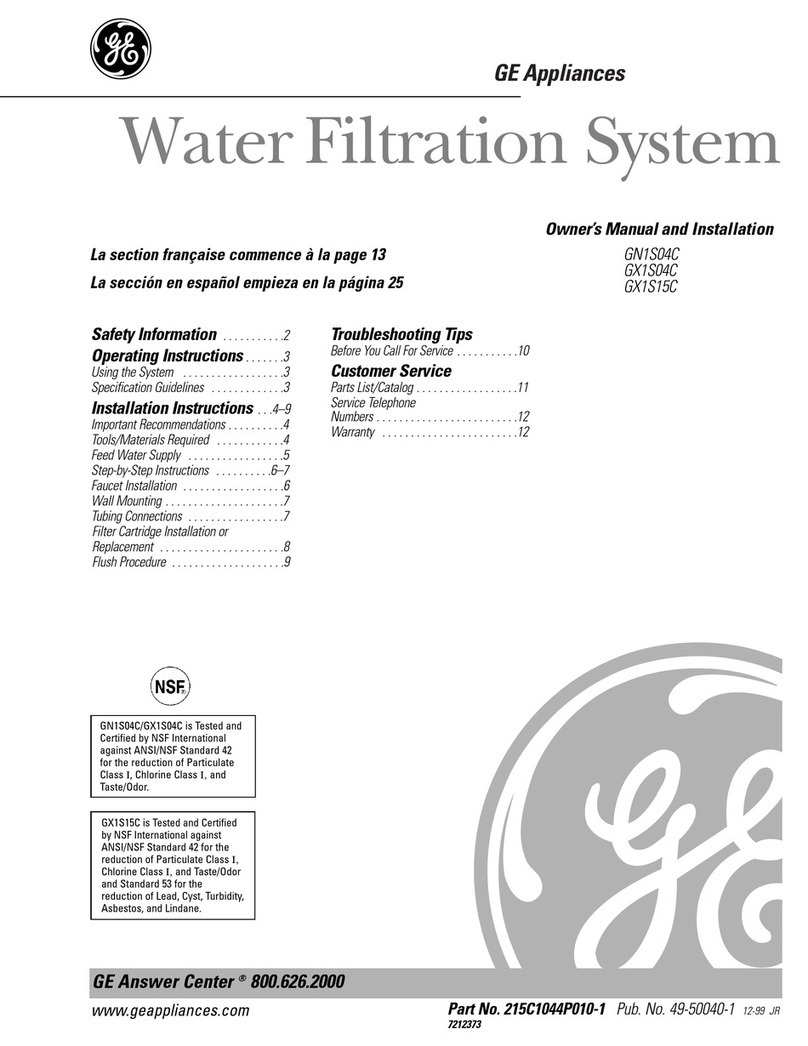

Installation Overview

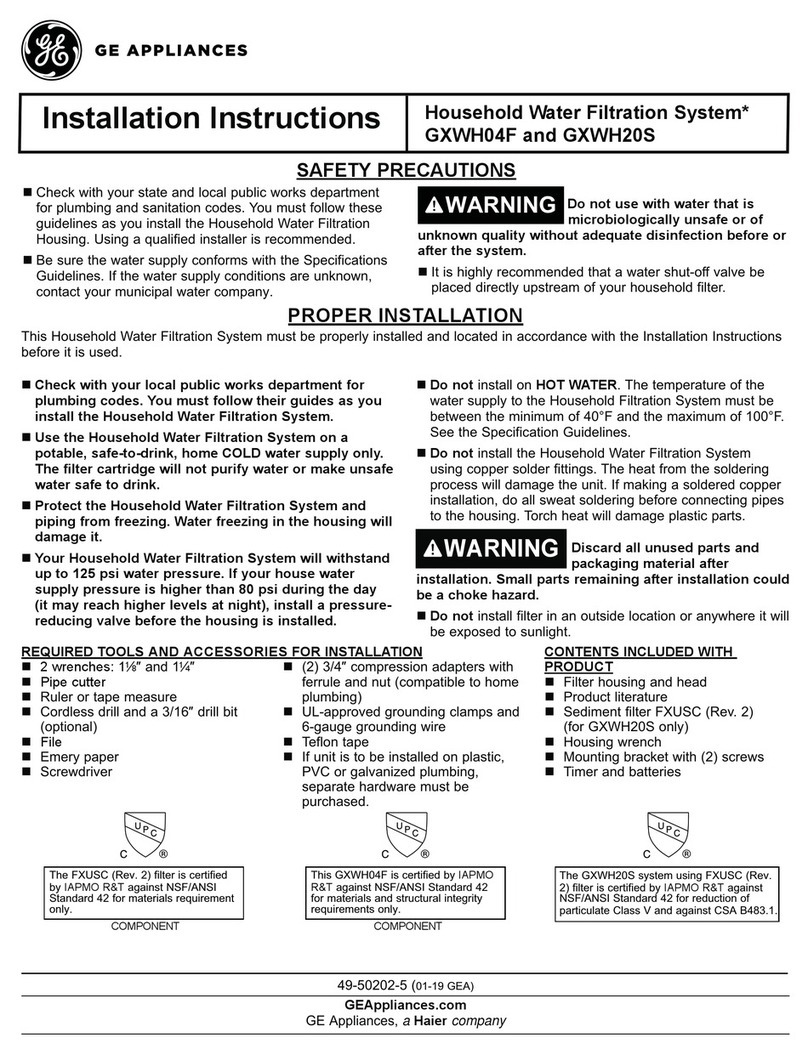

Installation Instructions.

Important Installation Recommendations

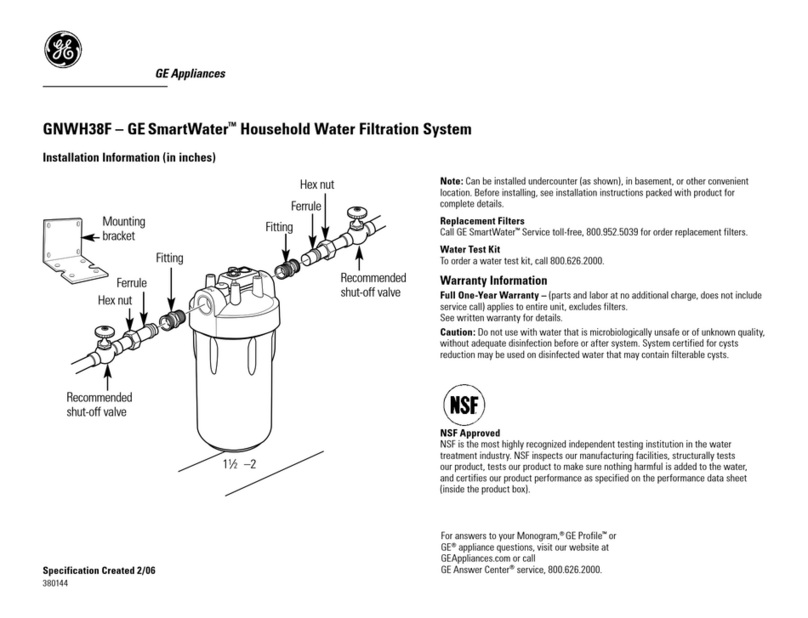

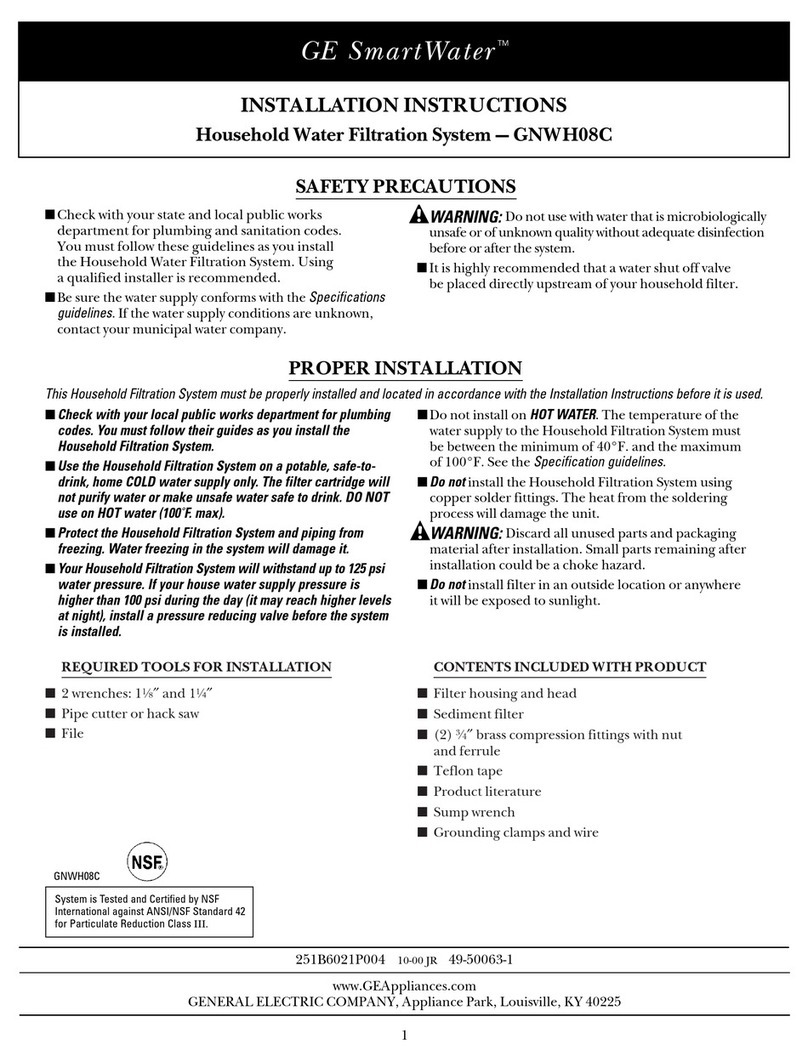

■Check with your local public works department for plumbing

codes. You must follow their guides as you install the Water

Filtration system.

■

Use the Water Filtration system on a potable, safe-to-drink, home

COLD water supply only. The filter cartridges will not purify water

or make unsafe water safe to drink. DO NOT use on HOT water

(100°F max.).

■Protect the Water Filtration system and piping from freezing.

Water freezing in the system will damage it.

■Your Water Filtration system will withstand up to 125 psi water

pressure. If your house water supply pressure is higher than

100 psi during the day (it may reach higher levels at night),

install a pressure-reducing valve before the system.

WARNING: Do not use with water that is

microbiologically unsafe or of unknown quality without

adequate disinfection before or after the system.

GXSL03C (rev. 2) and GXSV10C are certified for cyst

reduction and may be used on disinfected water that

may contain filterable cysts. The water should be tested

periodically to verify that the system is performing

satisfactorily. Small parts remaining after the installation

could be a choke hazard. Discard safely.

■Slotted and Phillips screwdrivers

■Pliers and adjustable jaw wrench

■Hand- or battery-powered drill and 1 ⁄ 4″bit (saddle valve

installation)

■Electric drill and drill bit to drill 1″–1 1 ⁄ 4 ″hole (type as

required) if mounting hole is needed for faucet

CAUTION: To avoid damaging the sink, consult

a qualified plumber or installer for drilling procedures.

Special drill bits may be needed for porcelain or

stainless steel.

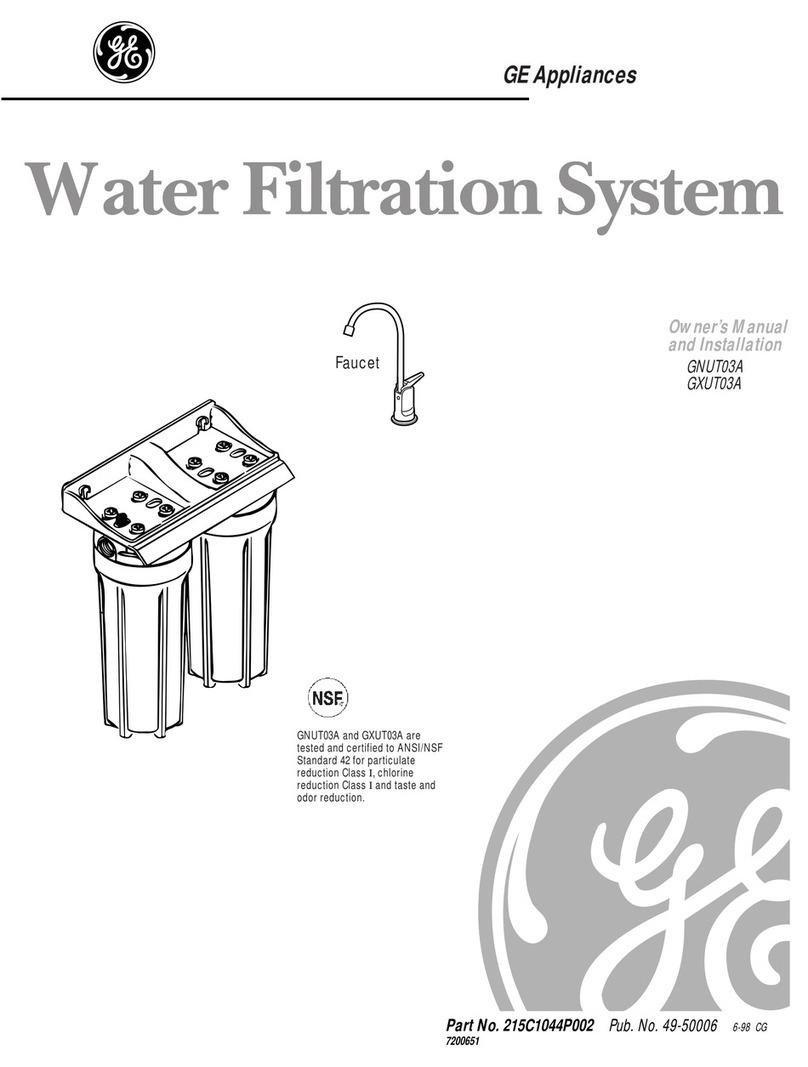

Contents included with the product:

■Water filter assembly, including mounting bracket

and screws

■Product Literature (Owner’s Manual and Installation,

Product Data Sheet, Owner Product Registration Card)

■Water supply/saddle valve

■Filtered water faucet for sink or countertop mounting

■Electronic indicator faucet base and battery pack

(GXSV10C only)

■3

⁄

8″tubing and fittings to make all needed connections

■Sump wrench

Filtered

water faucet

Sink

Battery pack

Hot

Shutoff valve

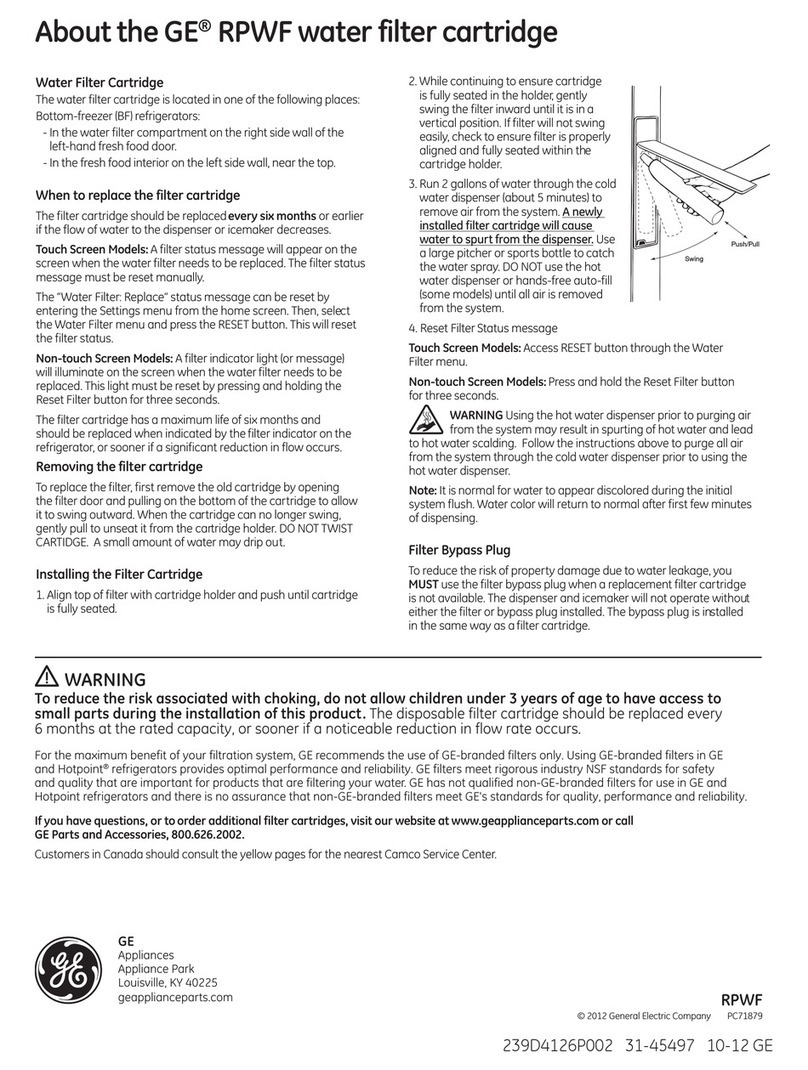

NOTE: To change the filter

cartridge, you must turn off the

water. A nearby shutoff valve is

convenient. Most sinks already

have shutoff valves on the

supply pipes.

Cold Water supply valve

Tubing insert

Tubing adapter

Compression nut

Water in

Water out

Tubing

Mounting

screw (2)

Filter I

Filter II

Locate the drinking water

system on the cold water

supply pipe, under the

kitchen and/or bathroom

sink, to filter the cold

drinking water.

Tools and Materials Required for Installation

Read entire manual. Failure to follow all guides and rules could cause personal injury or property damage.

Tubing