3

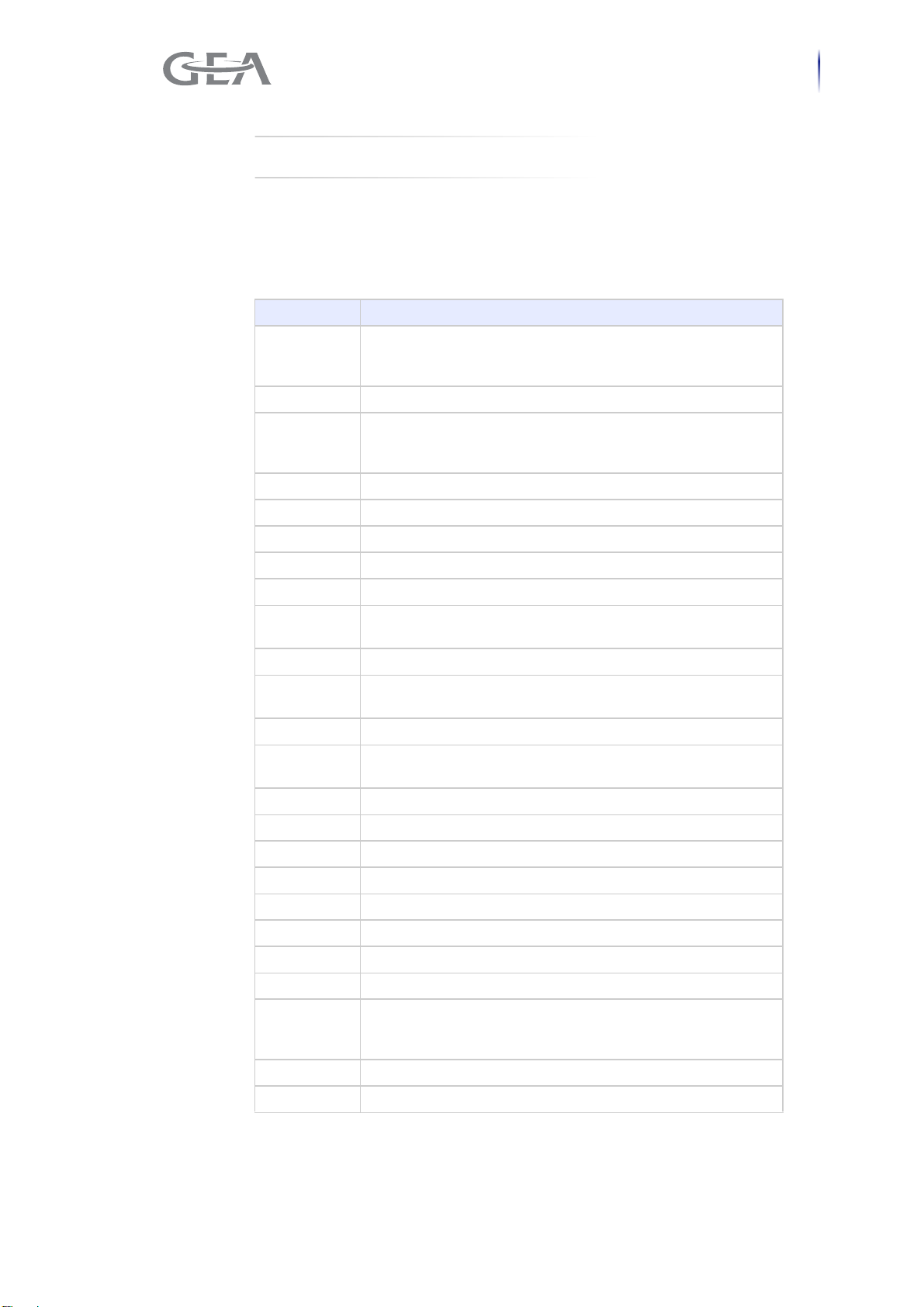

Table of Contents

Notes for the Reader ................................................................................................................ 5

Binding Character of These Operating Instructions .................................................................... 5

Notes on the Illustrations ............................................................................................................ 5

Symbols and Highlighting ........................................................................................................... 6

Abbreviations and Terms ............................................................................................................ 7

Safety ......................................................................................................................................... 9

Safety Note ................................................................................................................................. 9

Operator's Duties ........................................................................................................................ 9

Qualification of Staff ................................................................................................................. 10

Supplementary Regulations ..................................................................................................... 11

Instructions for the Safe Operation ........................................................................................... 12

•General Principles ................................................................................................................ 12

•Installation ............................................................................................................................ 12

•Commissioning/Setup Mode................................................................................................. 12

•Setting into Operation ........................................................................................................... 13

•Operation .............................................................................................................................. 13

•Shutting Down ...................................................................................................................... 13

•Maintenance and Repair ...................................................................................................... 13

•Disassembly ......................................................................................................................... 14

•Environmental Protection ..................................................................................................... 15

•Electrical Equipment ............................................................................................................. 15

•Explosion Protection ............................................................................................................. 15

Residual Risk ............................................................................................................................ 16

•Hazard Areas........................................................................................................................ 16

•Residual Dangers ................................................................................................................. 18

Declaration of Incorporation ................................................................................................. 19

Transport and Storage ........................................................................................................... 20

Scope of Supply ....................................................................................................................... 20

Transport .................................................................................................................................. 20

Storage ..................................................................................................................................... 20

Intended Purpose ................................................................................................................... 21

Designated Use ........................................................................................................................ 21

Operating Pressure and Nozzle Size ....................................................................................... 21

Requirements for the Operation ............................................................................................... 21

Improper Operating Conditions ................................................................................................ 22

ATEX Directive ......................................................................................................................... 22

Conversion Work ...................................................................................................................... 22

Installation and Commissioning ........................................................................................... 23

Operating Conditions ................................................................................................................ 23

Installation Dimensions ............................................................................................................. 23

Notes on Installation ................................................................................................................. 24

Filter/Strainer ............................................................................................................................ 24

Installing ................................................................................................................................... 24

Installation Position ................................................................................................................... 25