3

NOTE:

Notes are specific and important points which are informative and are included for further information

about the particular subject.

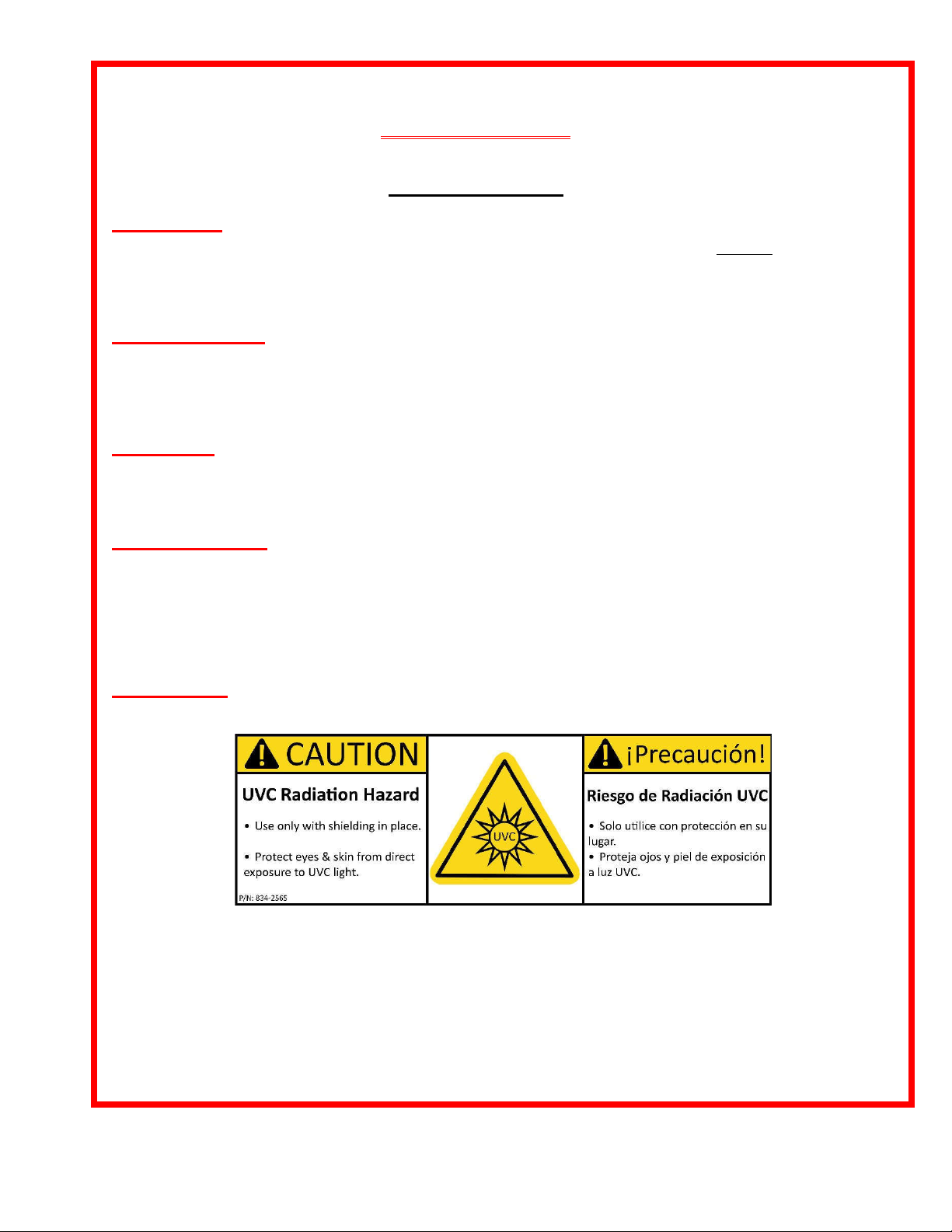

CAUTION!

Cautions are procedures, practices, or specific points of information which, if not carefully followed, may

result in damage to the machines or equipment or, may lead to minor personal injury.

WARNING! Warnings are procedures, practices, or specific points of information which, if not carefully

followed, may result in serious personal injury—even death—or, may result in severe damage to the

machinery or equipment. They are preceded by this exclamation diagram.

INTRODUCTION

Preface

This manual will only benefit all of us if you, and others responsible for the operation and maintenance of

this equipment, review this manual and keep it with the machine where it can be referenced for immediate

use.

For safety and reliable operation, custom equipment like this machine requires a working understanding

of the adjustments and principles of operation by the personnel involved.

To order parts, the correct part number, serial number, and model number of the equipment will be

required.

Throughout this manual, features and appearances may vary from your model. Due to CI (continuous

improvement), the pictures shown may not depict exactly your machine; however, the concepts are the

same.

In this manual, reference is made to the following terms:

Parts Ordering

Please refer to the machine model number and part number when ordering parts.

Our normal business hours are 8:00 a.m. to 5:00 p.m. USA Eastern Standard Time (EST), Monday

through Friday.

The information contained or disclosed by this document is considered proprietary by Geerpres. This document, items, and

information contained or disclosed herein shall not be used, copied, or reproduced in whole or in part, nor shall the contents be

revealed in any manner to any person unless written permission is obtained from Geerpres.