280618_MAN_IO-LINK IMPACT_12-2019_ENG

INDEX

1. GENERAL INFORMATION...............................................................................................................................................................4

1.1. General information .................................................................................................................................................................4

1.2. Copyright..................................................................................................................................................................................4

1.3. Correct use ..............................................................................................................................................................................4

2. MELT IO-LINK...................................................................................................................................................................................4

2.1. Impact IO-Link models.............................................................................................................................................................4

2.2. Transducer General Information .............................................................................................................................................4

2.3. Models .....................................................................................................................................................................................5

3. TECHNICAL DATA ...........................................................................................................................................................................6

4. MECHANICAL DIMENSIONS...........................................................................................................................................................7

5. INSTALLATION AND POSITIONING ON THE MACHINE ...............................................................................................................7

5.1. Installation seat........................................................................................................................................................................7

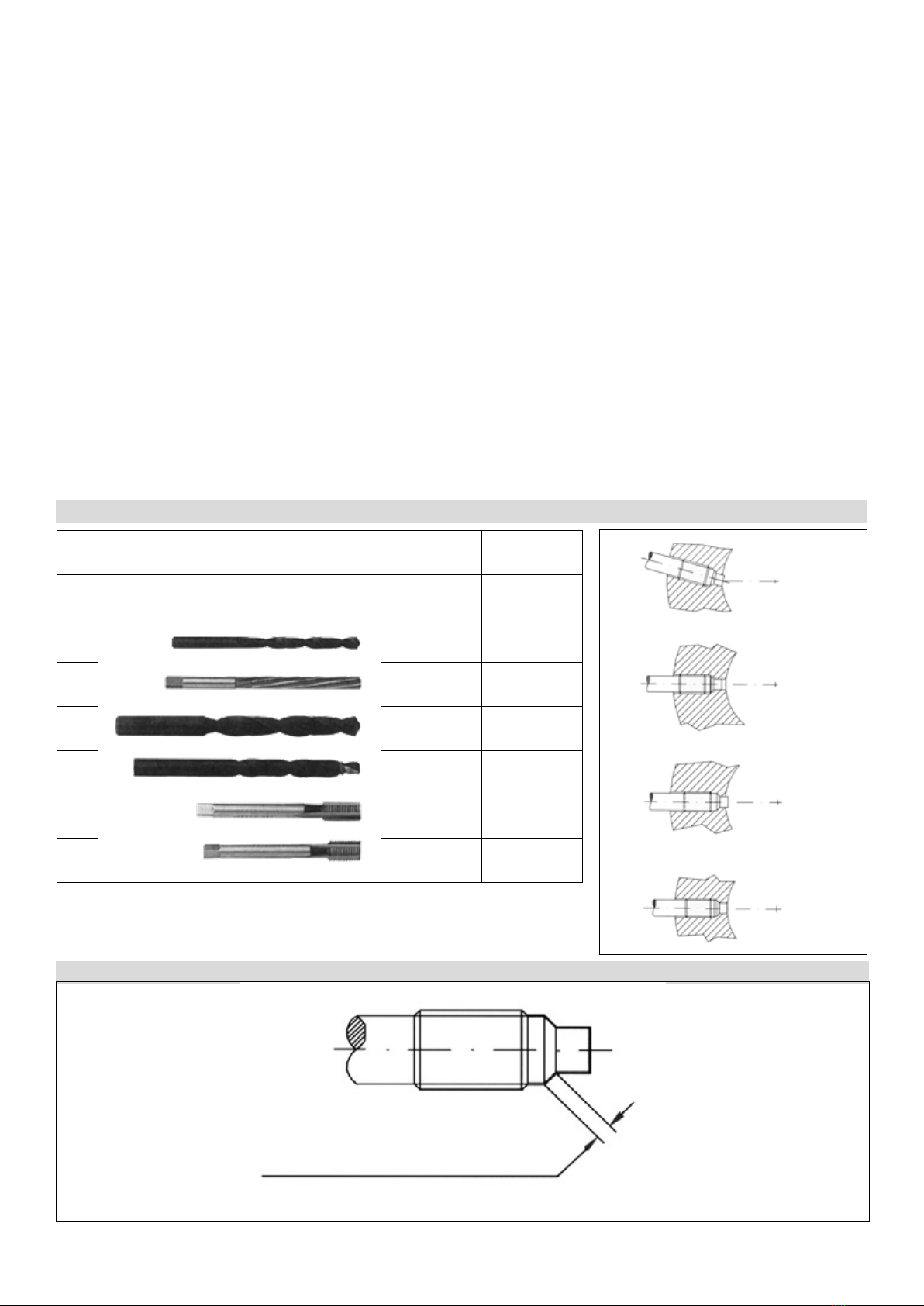

5.2. Drilling tool kit...........................................................................................................................................................................8

5.3. Torquing the sensor ...............................................................................................................................................................10

5.4. Connecting amplier ..............................................................................................................................................................10

6. INSTALLATION AND ELECTRICAL CONNECTIONS................................................................................................................... 11

6.1. General precautions............................................................................................................................................................... 11

6.2. Electrical installation .............................................................................................................................................................. 11

6.3. Standard reference ................................................................................................................................................................13

6.4. EMC and RoHS Requisites....................................................................................................................................................13

7. COMMAND MODES ......................................................................................................................................................................14

7.1. IO-Link Information ...............................................................................................................................................................14

7.2. SIO mode and IO-Link mode .................................................................................................................................................14

7.3. Process Data mapping (IO-Link)............................................................................................................................................14

7.4. Parameterization data............................................................................................................................................................15

7.5. LED behavior .........................................................................................................................................................................21

7.6. Switching signal channels (SSCs) conguration....................................................................................................................22

7.7. Reranging (LRV/URV) – only for SIL 2 / PL d analog output version –..................................................................................24

7.8. Relay Threshold change – only for SIL 2 / PL d relay output version – .................................................................................25

7.9. Damping lter parameter .......................................................................................................................................................25

7.10. Autozero command..............................................................................................................................................................25

7.11. Enable CAL parameter.........................................................................................................................................................26

7.12. Analog Out Type parameter .................................................................................................................................................26

7.13. Autocompensation effect on Impact series ..........................................................................................................................26

8. MAINTENANCE..............................................................................................................................................................................27

8.1. Maintenance ..........................................................................................................................................................................27

8.2. Transport, storage and disposal

9. FUNCTIONAL SAFETY NOTES (FOR SIL 2 / PL d CERTIFIED VERSIONS ONLY) -waiting for Notied Body certication-............28

9.1. Application..............................................................................................................................................................................28

9.2. Restrictions of use .................................................................................................................................................................30

9.3. Maintenance and periodic checks..........................................................................................................................................30

9.4. Mean Time to Restoration .....................................................................................................................................................31

9.5. Indication on response times .................................................................................................................................................31

9.6. Effects on the safety function of deviations in performance...................................................................................................31

9.7. Inhibition and suspension of the safety function ....................................................................................................................31

9.8. Indications and alarms...........................................................................................................................................................32