385190A_MAN_Installazione_MK4-IK4/SK4_11-2012_ENG

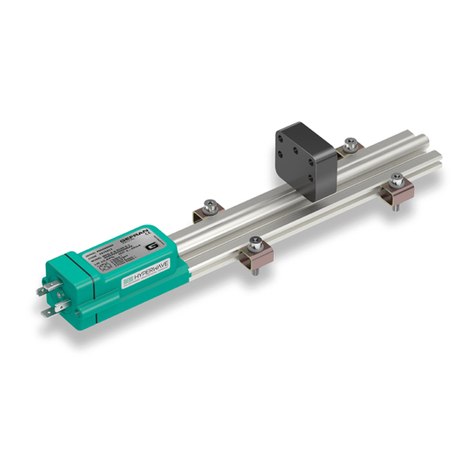

MK4 SERIES – CORRECT USE OF THE PCUR034 FLOATING CURSOR

Understandardconditions(Fig.1),thePCUR034cursormustbeinstalledonasupportmadeofnon-magneticmaterial

(suchasbrass,aluminium,orAISI316stainlesssteel).

Theinstallationkit,consistingoftwoscrews,twonuts,andtwowashers(allmadeofbrass),isincludedinthepackage.

Thecursor(Fig.2)mustbeinstalledwithmaximumattentiontohorizontalalignmentwiththetransduceraxis(maximum

toleranceis±2mm),aswellastothedistancefromthetransducersurfacefrom2to7mm(0to7mmforMK4-Sver-

sionwithdigitalSSIinterface).

Ifthereisnoalternativetoamagneticsup-

port,it’snecessarytopreventthesupport

fromchangingthemagneticfieldgenerated

bythecursor,becausethiscouldcausepro-

blemswiththecorrectmeasurementofthe

cursorposition.

Forthisreason,anon-magneticspacer

mustbeaddedbetweenthecursorandthe

magneticsupport(Fig.3-Sol.1).

Therecommendedspacerthicknessis15mm.

Iftheapplicationdoesnotpermittheinstal-

lationofanon-magneticspacer,it’spossible

toinstallthecursordirectlyonthemagnetic

support,beingcarefulnottoletthesupport

makedirectcontactwiththepartofthecursor

containingthemagnet(Fig.3-Sol.2).

Iftheapplicationrequiresinstal-

lationofmultiplecursors(twoor

more),thecursorsmustbemini-

mum75mmapart(Fig.4).

Rememberthatinordertoensu-

reprecisemeasurement,each

magnetmustbeinstalledatthe

samedistancefromthetransdu-

cersurface.

Inaddition,allcursorsmustbe

keptatthesameworkingtempe-

rature.

Fig.1 Fig.2

Totallength

Totalstroke

Support

Cursor

Screws

96 58

max±2mm

2...7mm

Fig.4

min75mm.

Fig.3

Non-magnetic

Support

Magnetic

Support

Support

magnetic

Non-magnetic

spacer

Cursor Cursor Cursor

Screws Screws Screws

Sol.1 Sol.2

Max

12mm