Rev. 00 12/22

4 • Table of contents OptiMove CR09-C

System parameters .............................................................................................. 30

Entering the system parameters ............................................................. 30

CAN bus ............................................................................................................... 34

General information ................................................................................. 34

Hardware ................................................................................................. 35

Determining device address (Node-ID) and Baud rate ........................... 36

DigitalBus parallel interface .................................................................................. 37

Overview .................................................................................................. 37

16 bits parallel bus structure.................................................................... 37

Command table and value ranges .......................................................... 39

Control sequence .................................................................................... 39

Software description ................................................................................ 41

Digital Connector CD02 with connection designations ........................... 42

Operation 43

Operation .............................................................................................................. 43

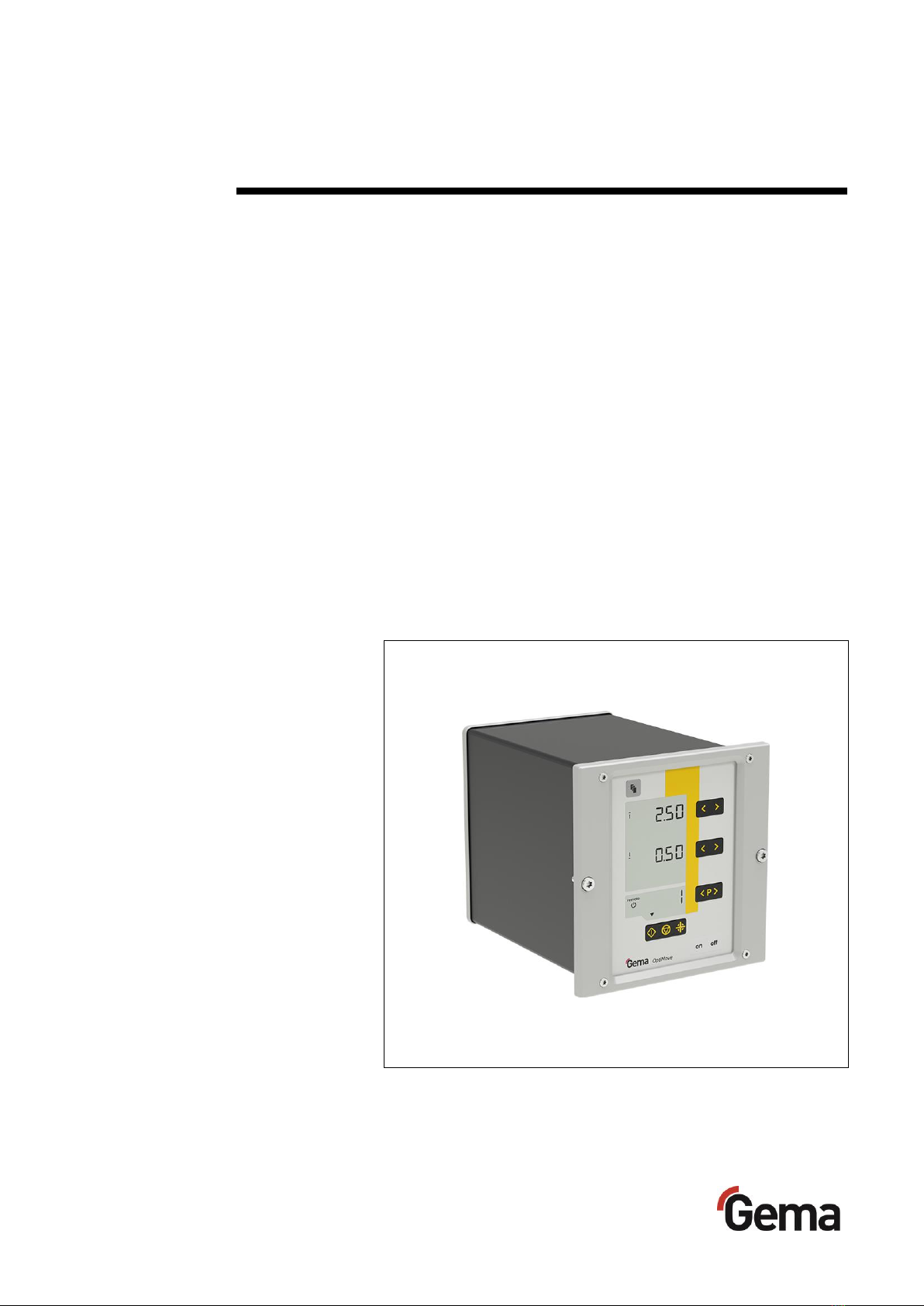

Operating the axis control unit .............................................................................. 43

Switch on/off the axis control unit ......................................................................... 43

Travel to reference point ....................................................................................... 44

Start/stop the axis ................................................................................................. 44

Program change ................................................................................................... 45

Displaying the cycle time ...................................................................................... 45

Edit programs ....................................................................................................... 45

Axes operating modes 47

General ................................................................................................................. 47

Pendulum operating mode ................................................................................... 47

Editing/Setting ......................................................................................... 48

Sequence program ............................................................................................... 48

Structure of a program step (procedure step) ......................................... 49

Programming example – positioning ....................................................... 50

Programming example – pendulum movements ..................................... 50

Programming example with path-time diagram ....................................... 51

Semiautomatic pendulum operating mode ........................................................... 51

Sequence program X_GunClean ......................................................................... 52

Setup .................................................................................................................... 52

Setup mode by keyboard (pendulum operating mode / semiautomatic

mode) ....................................................................................................... 52

Setup mode by keyboard (sequence program) ....................................... 53

Memory Reset ...................................................................................................... 54

Default values after RAM reset ............................................................... 54

Checking the software version ............................................................................. 55

Query of the hour counter ..................................................................................... 55

Decommissioning / Storage 57

Shutdown .............................................................................................................. 57

If in disuse for several days ..................................................................... 57

Storage conditions ................................................................................................ 57

Hazard notes ........................................................................................... 57

Type of storage ........................................................................................ 57

Storage duration ...................................................................................... 57

Space requirements ................................................................................ 57

Physical requirements ............................................................................. 58

Maintenance during storage ................................................................................. 58

Maintenance schedule ............................................................................. 58

Maintenance works .................................................................................. 58