V 04/13

OptiFeed B FPS19 Table of contents •1

Table of contents

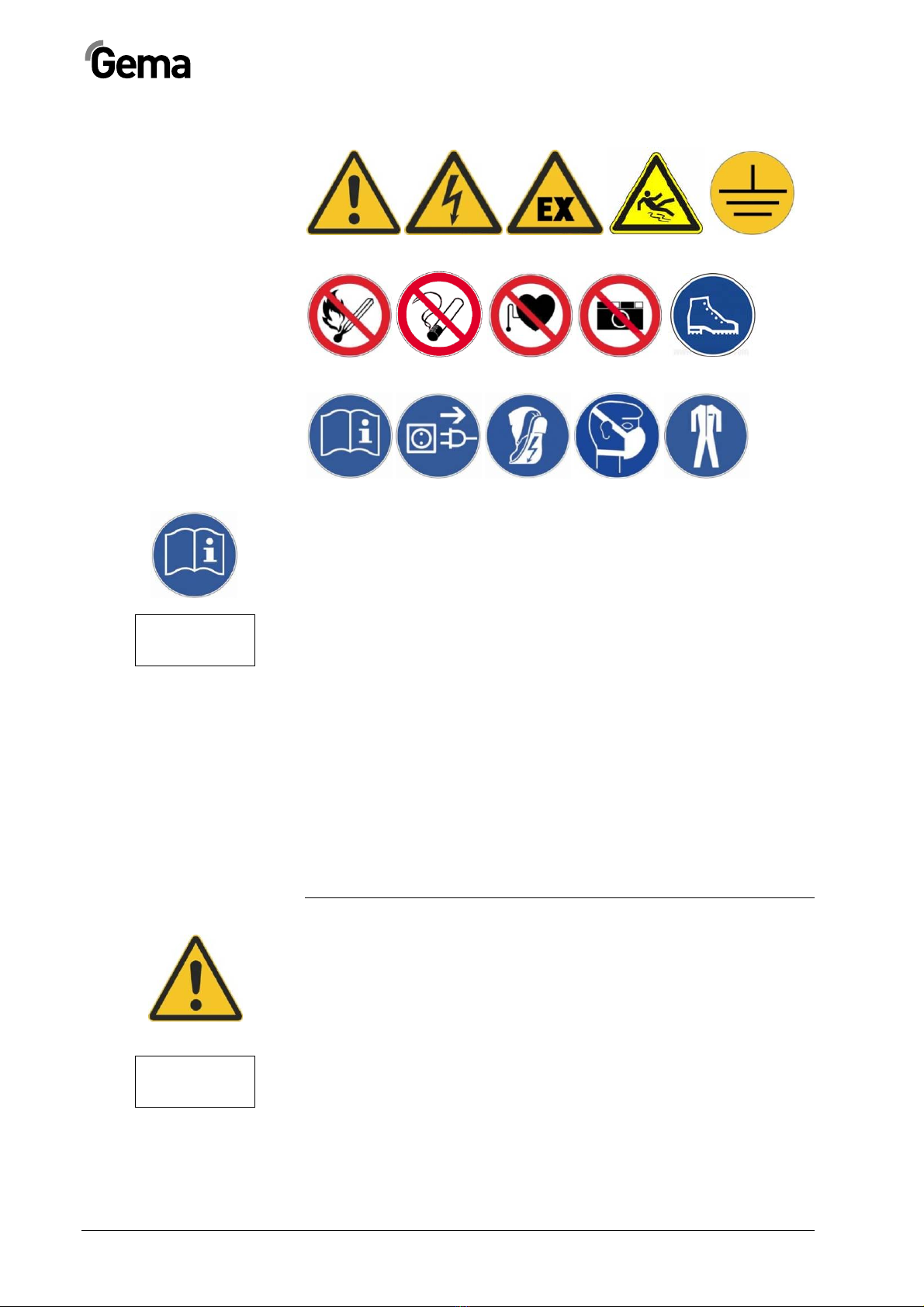

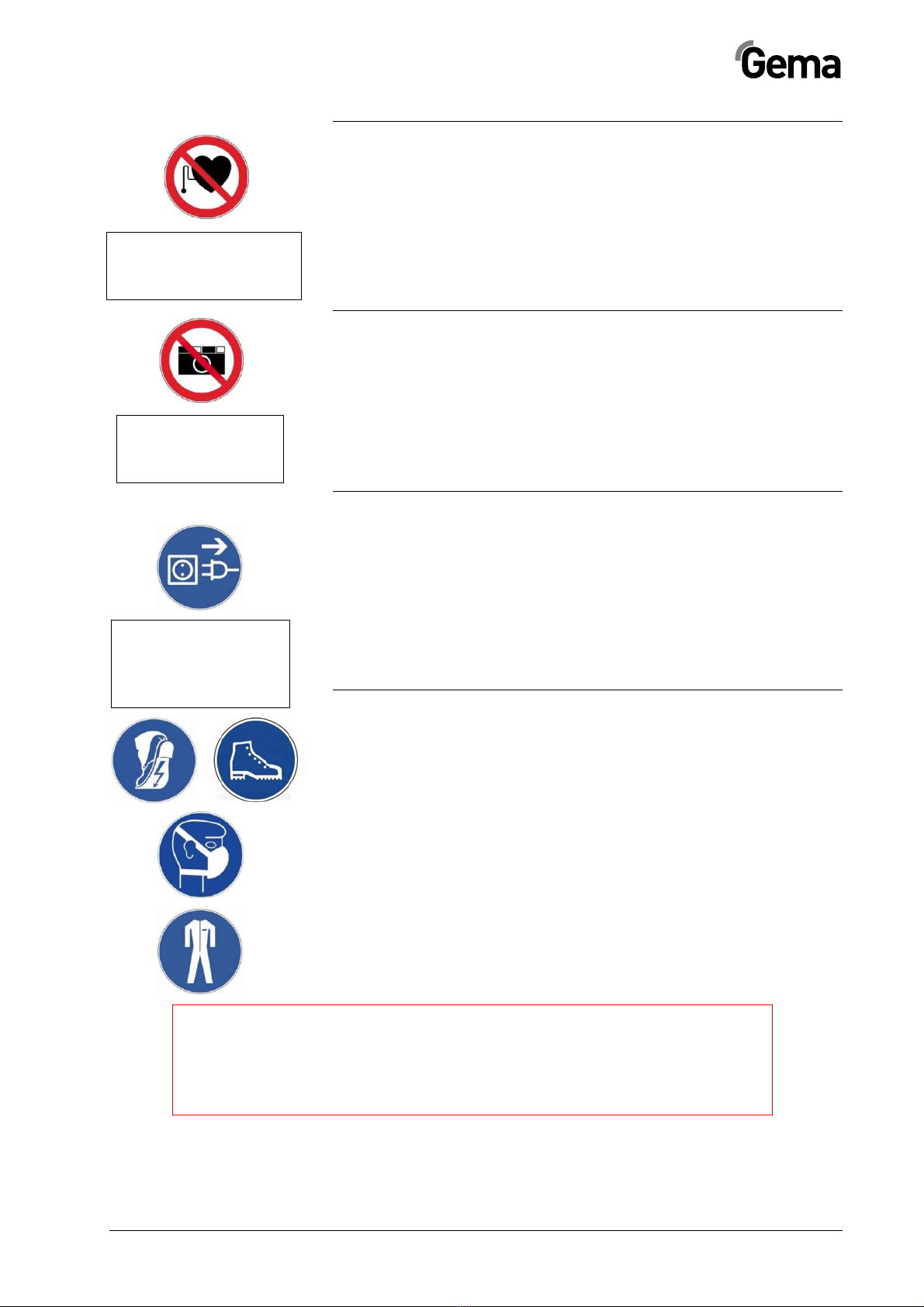

General safety regulations 3

Safety symbols (pictograms) ...................................................................................3

Conformity of use ....................................................................................................8

Product-specific safety measures ...........................................................................8

OptiFeed B FPS19 Fresh powder system..................................................8

About this manual 9

General information.................................................................................................9

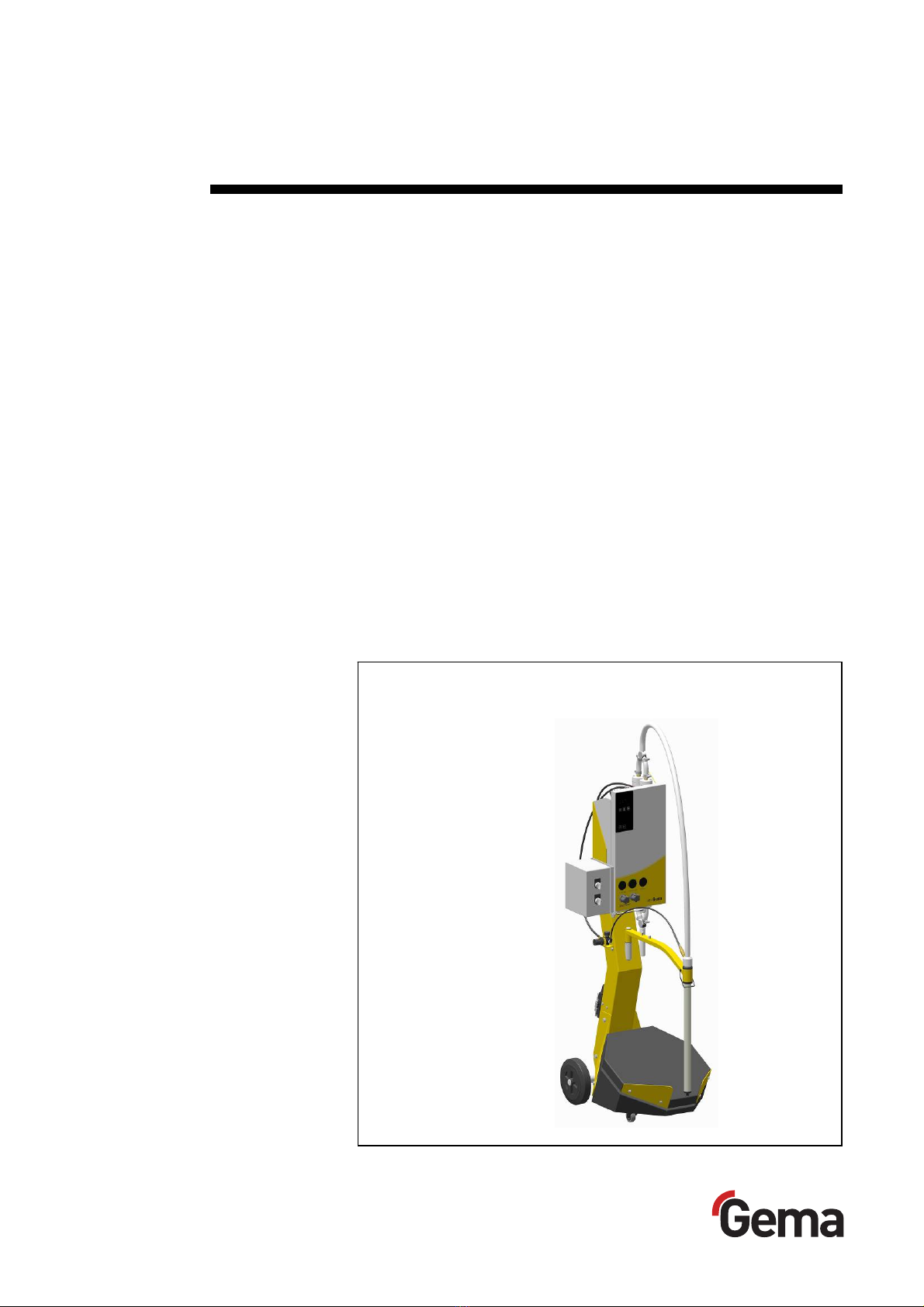

Product description 11

Field of application ................................................................................................11

Utilization ..................................................................................................12

Reasonably foreseeable misuse ..............................................................12

Technical data .......................................................................................................12

Electrical data...........................................................................................12

Pneumatic data ........................................................................................12

Conveying performance/powder output ...................................................13

Dimensions...............................................................................................13

Processible powders ................................................................................13

Design and function...............................................................................................14

General view ............................................................................................14

Scope of delivery...................................................................................................15

OptiFeed B FPS19 ...................................................................................15

Accessories (Option) ................................................................................15

Typical properties - Characteristics of the functions .............................................15

Processing the powder directly from the original powder manufacturer's

container...................................................................................................15

Start-up 17

Preparation for start-up .........................................................................................17

Basic conditions .......................................................................................17

Set-up ....................................................................................................................17

Initial start-up 19

Operation...............................................................................................................20

Powder hose rinsing.................................................................................21

Color change .........................................................................................................22

General information..................................................................................22

Shutdown...............................................................................................................23

Cleaning and maintenance 25

Daily maintenance.................................................................................................25

Weekly maintenance .............................................................................................25

If in disuse for several days...................................................................................25

Cleaning ................................................................................................................26

Cleaning the fluidizing/suction unit...........................................................26