Tennsmith PR16 Guide

MODEL PR16 POWER ROTARY

OPERATION, PARTS & MAINTENANCE MANUAL

6926 Smithville Hwy. McMinnville, TN 37110

Phone: 931-934-2211 • Fax: 931-934-2200

Email info@tennsmith.com

www.tennsmith.com

Proudly Made in the USA

A Family Tradition Since 1928

MACHINE SPECIFICATIONS

Model PR16

Maximum forming capacity, mild steel 16 gauge / 1,6mm

Maximum forming capacity, stainless steel 20 gauge / 1,0mm

Maximum Throat length 10 in. / 254mm

Working Speed variable 3 to 45 rpm

Motor-230, 3 phase, 60Hz 1/2 hp

Amp Draw of 3 phase motor 1/2hp 1.5 amps

Motor-230, 1phase, 60Hz 1/2 hp 230 volt 1 phase

Amp Draw of 1 phase motor 3hp 2 amps

Shipping weight 350 lbs. / 159 kg

APPROXIMATE SHEARING, BENDING AND FORMING

CAPCITIES FOR VARIOUS MATERIALS COMPARED TO MILD STEEL

Mild Steel Capacity 20ga. 18ga. 16ga. Mild Steel Capacity 20ga. 18ga. 16ga.

NON-FERROUS METALS FERROUS METALS

Aluminum Iron-dead soft 20ga. 18ga. 16ga.

1100-0, 2024-0 .070 .090 .125 Steel low carbon

5052-0. 6061-T4 .070 .090 .125 1074, 1095 C.R. Spring Steel 24ga. 22ga. 20ga.

2024-T3, 5052-H34 .048 .063 .090 Hot Rolled 20ga. 18ga. 16ga.

5086-H36, 6061-T6 .048 .063 .090 Low carbon Cold Rolled 20ga. 18ga. 16ga.

Copper and Alloys Stainless Steel Annealed 24ga. 22ga. 20ga.

Electrolytic Copper 18ga. 16ga. 14ga. OTHER MATERIALS

Bronze Commercial 18ga. 16ga. 14ga. Plastics

Brass 70-30 18ga. 16ga. 14ga. ABS Compounds .120 .150 .200

Nickel Alloys Polycarbonate .075 .105 .125

Inconel 600 24ga. 22ga. 20ga. Printed Circuit Boards

Monel R405 24ga. 22ga. 20ga. Copper-Clad

Nickel 200A Annealed 24ga. 22ga. 20ga. Epoxy Laminate .086 .115 .150

Zinc as Rolled 20ga. 18ga. 16ga.

Approximate Gauge Equivalents

Gauge 28 26 24 22 20 18 16 14 12 11 10

Inches .015 .018 .024 .030 .036 .048 .060 .075 .105 .120 .135

Millimeters .38 .46 .61 .76 1.00 1.25 1.60 2.00 2.70 3.05 3.50

6926 Smithville Hwy McMinnville, TN 37110

Phone: (931) 934-2211 • Fax (931) 934-2220

www.tennsmith.com

FOREWORD

This manual has been prepared for the owner and operators of the TENNSMITH Model

PR16 POWER ROTARY.

Its purpose, aside from operation instruction, is to promote safety through the use of accepted

operating procedures. Read all instructions thoroughly before operating your machine.

Also contained in this manual is the parts list for your PR16. It is recommended that only

TENNSMITH factory authorized parts be used for replacement parts.

WARRANTY

The Model PR16 has a three year limited warranty from the date of purchase. The terms of the

warranty are stated on the warranty registration card shipped with your machine. Please

complete and return this card to activate your warranty.

SAFETY

1. Each employee involved with the installation, operation and maintenance with this

machine must review and understand the section of the manual entitled safety.

2. Always disconnect the machine from the main power supply prior to any maintenance

and repair work to the machine.

3. The machine must only be operated by authorized personnel that have been trained and

fully understand the operation of this machine.

4. To ensure that there are no conflicts of authority, responsibilities for machine operation

and maintenance must be clearly defined and carried out by trained personal, prior to the

installation and regular operation of this machine.

5. The operator must ensure that no unauthorized personnel work with this machine with

regard to either operation or maintenance.

6. Electrical hazards such as shock exist with this machine. All work regarding electrical

installation and maintenance must be performed by dully-trained personnel. Before

initial connection, check to verify that the operating voltage on the label attached to the

electrical box complies with the main voltage of the electrical connection used for this

machine.

7. All safety devices and labels must not be removed from the machine

8. The work area around the machine must be clear of obstructions, which could interfere

with the proper operation of the machine.

9. The main electrical supply line must be disconnected prior to any work performed inside

the electrical cabinet. Proper lockout procedures must be performed to ensure that the

main electrical supply cannot be activated during any work performed inside the

electrical box.

10.Modification or conversion of this machine is prohibited.

11.The operator of this machine must ensure that non-authorized personnel cannot operate

the machine. Lock out tags must be used on the main disconnect while the machine is

unused by the trained and authorized personnel.

12.The operator of this machine must ensure that his hands and body parts do not enter the

area of the forming rolls when the machine is in use.

13.Danger! Maintain a safe distance from the machine when it is activated. Hands and

fingers can be crushed. Wear protective clothing and work boots while operating the

machine. Do not wear loose clothing, rings or any jewelry while operating this machine.

Work gloves should only be used outside of the danger area of the forming rolls.

14.The operator must review the machine and work area for any possible hazards prior to

operating the machine. Any hazards must be reported to the proper personnel.

15.Use work-holding devices such as tongs for handling small works pieces.

16.Never exceed the rated capacity of the machine.

DO NOT OPERATE THE PR16 POWER ROTARY WITHOUT SAFETY

WARNING LABELS AND SHEET METAL COVERINGS GUARDS IN

PLACE.

SAFETY LABELS

RECEIVING THE MACHINE

1. Any damage that may have occurred during shipping must be reported immediately.

2. Use caution in transporting the machine within your facility. The machine is top heavy.

3. Strap through the two lifting rings located on the top of the main housing of the machine

and lift the machine off of the shipping pallet. Note* the machine has an approximate

shipping weight of 350 lbs. be sure that your lifting mechanisms can handle that load.

4. After the machine has been removed from the shipping pallet, it should be leveled and

bolted to the floor using ½ inch lagging bolts.

5. A qualified electrician should be used to connect the machine to the main electrical

supply; all cables have been prepared so that only the main supply line is all that needs

to be connected to the terminals inside the electrical box. Please consult Tennsmith if

any questions arise during electrical installation.

OPERATION SAFETY

1. Warning! Due to the nature of the machine and the necessity to feed parts by hand

into the machine while it is turning, great care must be followed to ensure that fingers,

hands, and body parts do not come near the forming rolls when in use.

2. Warning! There is also a danger to fingers and hands while the upper shaft is being

set to the proper forming pressure. The upper shaft will move downward towards the

lower shaft. Care must be taken to ensure that hands, fingers, and body parts are

clear of the two shafts will forming pressure is being set.

3. Protective clothing such as hairnets, tight clothing, and tight fitting protective gloves

should be used while operating this machine.

4. Prior to any work being formed, each operator must be thoroughly instructed as to the

proper way to handle and guide the work pieces in a safe manner so that the

necessary safety clearances between the operator and the machine is met.

MODEL PR16 PART’S VIEW

MODEL PR16 PARTS BREAKDOWN

Part Number Description Number Required

100 Top Arbor Shaft 1

101 Bottom Arbor Shaft 1

104 Gear 2

105 Housing 1

110 Tension Ring 1

111 Top Arbor Bushing 2

112 Arbor Bearing 2

113 Front Arbor Block 1

114 Rear Arbor Block 1

115 Thrust Bearing 9

117 Bottom Arbor Adjusting Block 1

120 Top Arbor Adjusting Housing 1

123 Housing Sub Plate 1

124 Stand 1

125 Stand Sub Plate 1

127 Snap Ring 2

130 Material Guide 1

132 Bottom Arbor Adjustment Handle 1

137 Rear Cover Plate 1

138 Top Housing Cover 1

139 Tension Cover 1

140 Bottom Housing Cover 1

OPERATION of the MODEL PR16

1. The upper arbor (100) of the PR16 is depth controlled either by either by a crank

handle located on the top the main cast body of the machine or by hydraulic powered

depth selection, depending on which model you have.

2. The lower arbor (101) has in and out horizontal adjustment that is controlled by the

lever handle designated part #132 in this manual.

3. An adjustable material guide part #130 is provided to serve as a stop to guide your

against while operating this machine.

4. The rolls are secured to the end of the shaft via a small circular plate located on the

end of each shaft. An allen wrench is needed to lock and unlock the plate. Be sure

that the power is in the off position when adjusting or replacing the rolls. Also, be

sure that the rolls are properly seated against the shaft and secured with the circular

plate before resuming operation of the machine.

5. Hydraulic Depth Selection Equipped Machines Only! The pressure adjustment

knob (figure 1) is used to set the pressure rating of the hydraulic clamp tension. The

range of the hydraulic pressure is 0 to 2700 psi. The amount of pressure needed will

vary depending upon the material type and thickness, and upon the profile or rolls

being used. The hydraulic pressure will show a 0 reading on the indicator dial until

the top roll engages the material or lower roll. Please consult the factory if you have

any questions regarding the pressure adjustment. The Hydraulic depth selection

machines are also equipped with a depth selection switch (figure 2) that allows you to

jog the upper shaft up or down to engage or disengage the work piece. The proper

depth is determined by material type and thickness being formed. It is advised to use

a scrap piece of the material being formed to determine the proper depth selection

prior to beginning a production run. The machine is also equipped with a directional

selector switch that determines the rotation of the rolls. The switch is located on the

front of the electrical box facing the operator. The 3 positions on the switch are; 1.

Forward 2. Off 3. Reverse. Forward and reverse are engaged by the foot switch

(figure 3) provided with the machine. The 2. position (off) allows the operation to

engage the depth selection and adjust the hydraulic pressure of the machine without

the possibility of the rolls being engaged by the footswitch. VERIFY THAT THE

DIRECTIONAL SELECTOR SWITCH IS IN THE OFF POSITION WHILE SETTING

THE UPPER SHAFT DEPTH WITH THE DEPTH SELECTOR SWITCH.

6. The standard machines have a hand crank adjustment knob located at the top front

of the housing (105) of the machine. The adjustment knob controls the depth either

up or down, of the upper shaft.

7. Each machine is equipped with a lower roll adjustment handle (part 132). This

adjustment allows for the horizontal adjustment of the lower arbor (101) either

towards or away from the operator. This movement is determined by rolls be used

and profile that you are trying to achieve. Figure 4 shows the roll adjustment handle

in detail. The adjustment includes a locking handle that locks and unlocks the lower

roll position. To move the lower roll unlock the adjusting handle and move the knob

under the handle either up or down depending upon the desired position of the lower

roll. If you have any questions regarding this adjustment, please consult the factory.

8. The Material Guide Part (130) is used to serve as a stop for the end of the material to

run against as it is being formed. The guide can be moved either in or out as needed

to confirm the profile being formed. Figure 5 shows the locking screw that locks and

unlocks the material guide.

MAINTENANCE AND LUBRICATION

1. Warning! The power must always be disconnected prior to any scheduled

maintenance of this machine. Turn the power off at the main disconnect and secure

with a safety lock. Service, maintenance and repair should only be carried out by

authorized personnel.

2. Models with the hydraulic depth selection option require a 2-quart capacity oil reserve

located on underneath the main housing. Check the tank monthly to verify that the oil

level is at the lower edge of the filler opening. The oil used at the factory is a T46

Shell Oil hydraulic fluid. Please contact the factory if you have any questions

regarding types and quantity of oil needed for your unit. The picture on the following

page shows the location of the filler opening under the main housing.

3. We recommend that the hydraulic oil be changed once annually. The drain plug

located between the hydraulic motor and the reserve tank. Please consult the factory

if you have any questions regarding this procedure.

4. Industrial grade grease should be applied monthly to the drive gears (part #104).

Again, power must be disconnected before maintenance of this machine. The figure

on the following page shows the top cover (part # 139) removed to show the access

to the drive gears (104).

5. A light film of industrial grade lubricant oil should be applied monthly to all exposed

metal working parts such as the drive shafts (100 & 101). Clean the area of all

excess oil before operating the machine.

6. Replace all covers and protective devices before operating the machine.

PLEASE CONSULT THE FACTORY AT 931-934-2211 IF YOU HAVE ANY

QUESTIONS REGARDING THE SAFETY, OPERATION OR MAINTENANCE OF THIS

MACHINE.

Available Rolls for the Model PR16 Power Rotary

Additional Rolls are Available. For Custom Applications Please Contact Tennsmith Inc.

Table of contents

Other Tennsmith Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

WOOD'S POWR-GRIP

WOOD'S POWR-GRIP MRTALPCH611LDC3 instructions

dymax

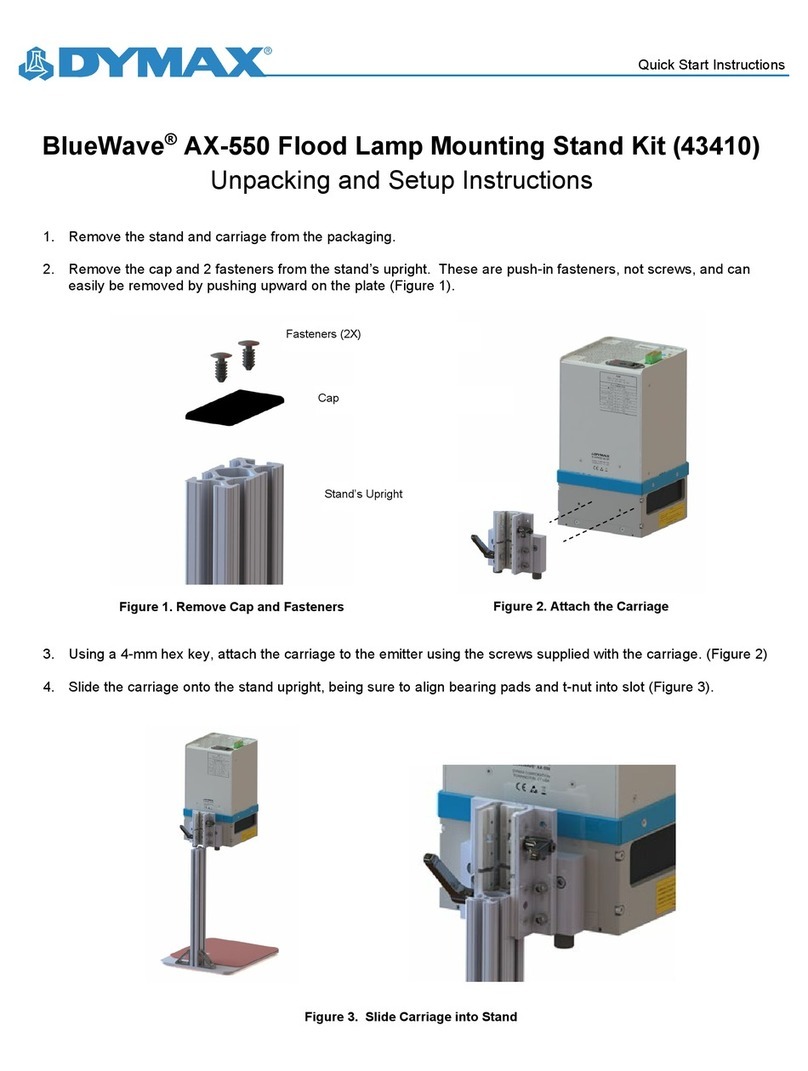

dymax BlueWave AX-550 Quick start instructions

Vaughan

Vaughan ROTAMIX SYSTEM Installation, operation & maintenance instructions

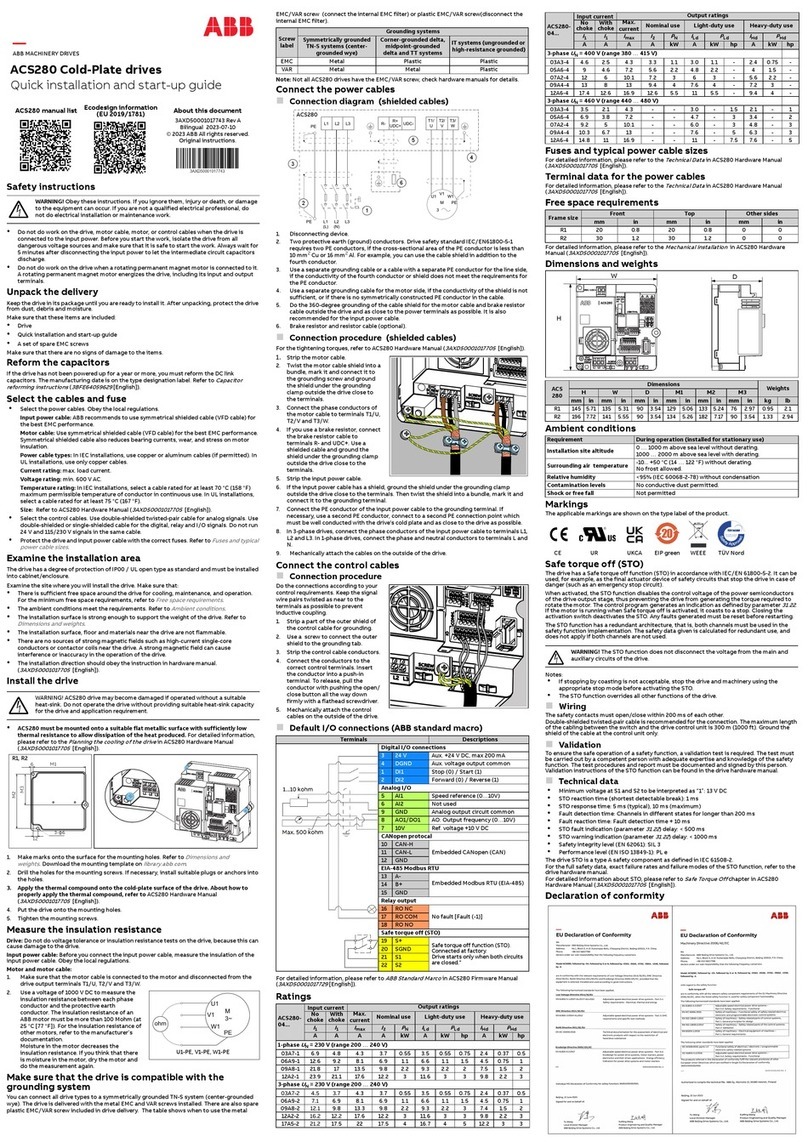

ABB

ABB ACS280 Quick installation and start-up guide

HEIDENHAIN

HEIDENHAIN ERN 9080 Mounting instructions

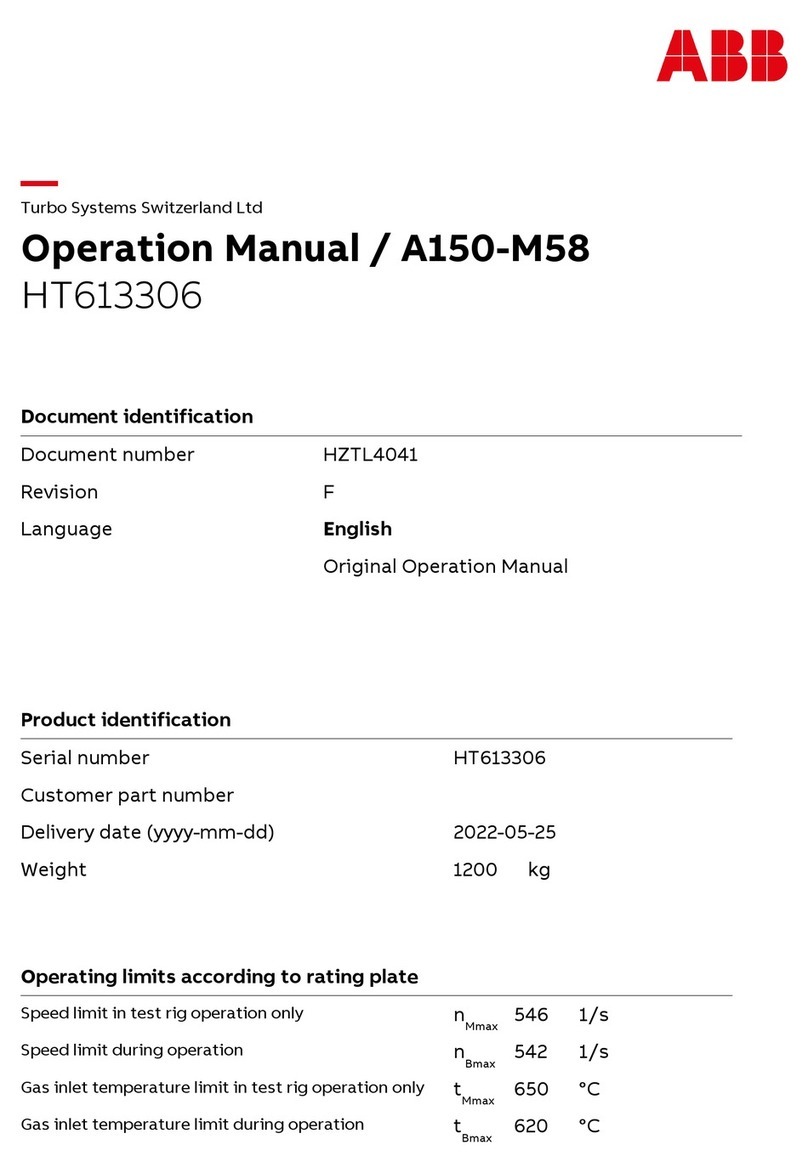

ABB

ABB HT613306 Operation manual