2

PREFACE

SPECIFICATIONS

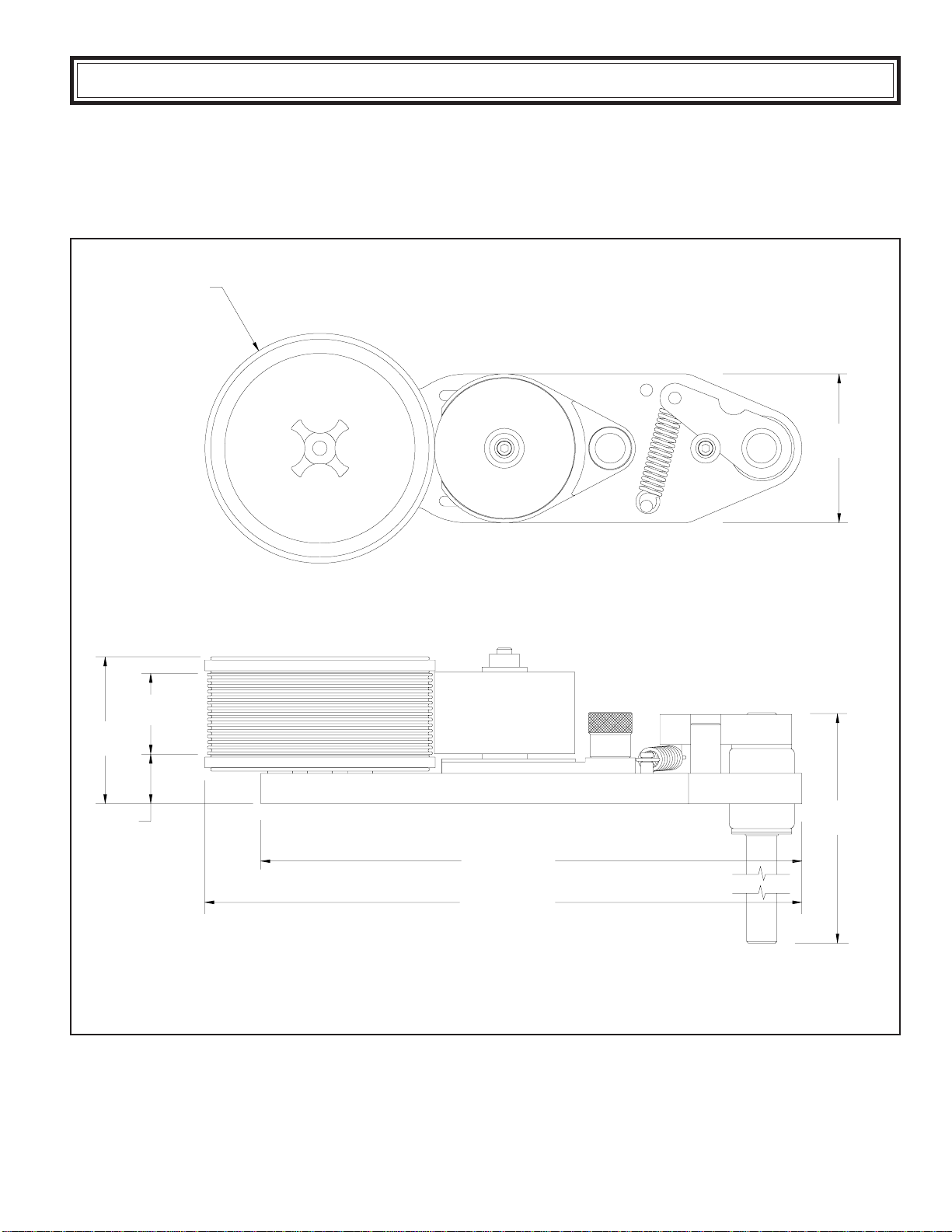

MS-120NI-LeftHandMount

MS-150NI-LeftHandMount

MS-180NI-LeftHandMount

MS-220NI-LeftHandMount

MS-250NI-LeftHandMount

MS-280NI-LeftHandMount

IndexingandNon-IndexingModels

MountingConfigurations

Printing Dies

InkRolls

Reservoir Roll Covers & 4oz. Reservoir Ink Cartridges

QUICK START

Pre-InkingMicrocell Rolls

InstallingthePre-InkedRoll

Installing the Printing Dies

Adjusting the Inking System

CODERINSTALLATION

CartonAlignment

Die Positioning for Indexing Coder Models

MAINTENANCE

Installing the Optional Reservoir Roll Covers

Installing the 4oz. Reservoir Ink Cartridges

Pre-Inking Neoprene & XF Neoprene Foam Rolls

Cleaning the Coder

Cleaning the Printing Dies

MOUNTINGCONFIGURATIONCONVERSION

Right-Hand & Left-hand Field Conversion

Changing Print Drum Sizes

PARTS DIAGRAMS & PARTS LISTS

IMPORTANT NOTE

UNIVERSAL products are manufactured to exacting standards and every available step has been taken to assure your

complete satisfaction. It is most important, however, that the instructions contained in this manual are read and carefully

followed for best results. Failure to do so may result in unsatisfactory performance, damage to the equipment and personal

injury.

- LIMITED WARRANTY -

UNIVERSAL PorousMidsizeCodersare guaranteedto befree fromdefects inmaterials andworkmanship fora periodof

90 days from the date of purchase. Components found to be defective during this time will be repaired free of charge if

returnedto thefactory.Damageresultingfrom useofimproperinks,improper installation,oroperation isnotcoveredunder

thescopeof thiswarranty. Forwarrantyservice pleasecontact ourCustomerService Department.

3

4

5

6

7

8

9

10

10

11

12

13

14

15

16

17

18

20

22

22

23

24

24

25

26

27

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○