PartNo.97866 GenieTMZ-34/19 5

Operator's Manual

Fourth Edition • First Printing

SAFETY RULES

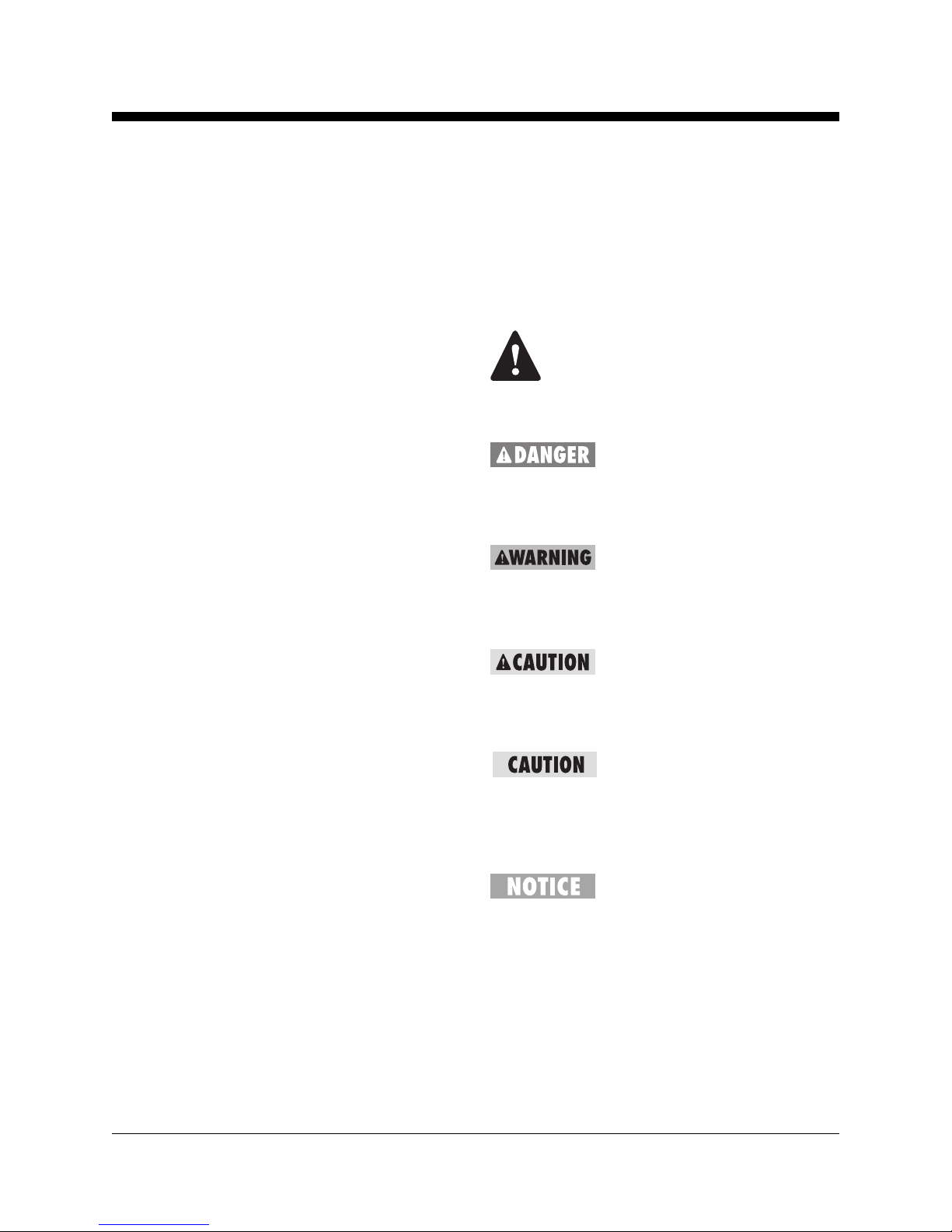

Decal Legend

Genie product decals use symbols, color coding

and signal words to identify the following:

Safety alert symbol—used to alert

personneltopotentialpersonalinjury

hazards. Obey all safety messages that

follow this symbol to avoid possible injury

ordeath.

Red—usedtoindicate the

presence of an imminently

hazardous situation which, if not

avoided, will result in death or

seriousinjury.

Orange—usedtoindicatethe

presence of a potentially

hazardous situation which, if not

avoided, could result in death or

seriousinjury.

Yellow with safety alert symbol—

used to indicate the presence of a

potentiallyhazardoussituation

which, if not avoided, may cause

minorormoderateinjury.

Yellow without safety alert

symbol—used to indicate the

presence of a potentially

hazardous situation which, if not

avoided, may result in property

damage.

Green—used to indicate operation

or maintenance information.

Towing Hazards

Read, understand and obey all of your tow vehicle

manufacturer’srecommendations,warningsand

instructions before towing this machine.

Donottowthemachineunlesstheboomhold-down

latches are securely locked in place.

Do not overload your tow vehicle. Check the

manufacturer'sGrossVehicleWeightRating

(GVWR). To obtain the gross vehicle weight, add

the tongue weight of the trailer to the vehicle weight

(includingvehicle,passengersandcargo).

Do not load cargo on the machine. The TMZ-34 is

not designed to carry any extra cargo.

Be sure the hitch is securely attached to the tow

vehicle.

Be sure the safety chains (if required) are securely

attached to the tow vehicle.

Be sure that all driving lights are operational.

Be sure all hitch components, lights and mirrors

and methods of attaching the trailer to the tow

vehicle conform to local, state and federal

regulations.

Do not tow the machine on public roads unless it

meetsallgovernmentalregulationsfortowing.

Do not exceed 60 mph / 97 km/h. Obey all local

andnationaltowingspeedlaws.

Be sure to chock the wheels of the trailer when

parking on a hill.