_ ! _ _'_%_ _%_ _ %_ 4'__ %_

Garage Doors are heavy objects that move with the help of springs

under high tension and electric opening equipment. Since moving

objects, springs under tension, and electric opening equipment

may cause injuries, your safety and the safety of others depend on

you reading and understanding the information in this manual.

If you have garage door related questions or do not understand the

information presented, call your nearest Genie Factory Authorized

Dealer listed at www.geniecompanyocom, or customer Service at

1-800-35-GENIE..

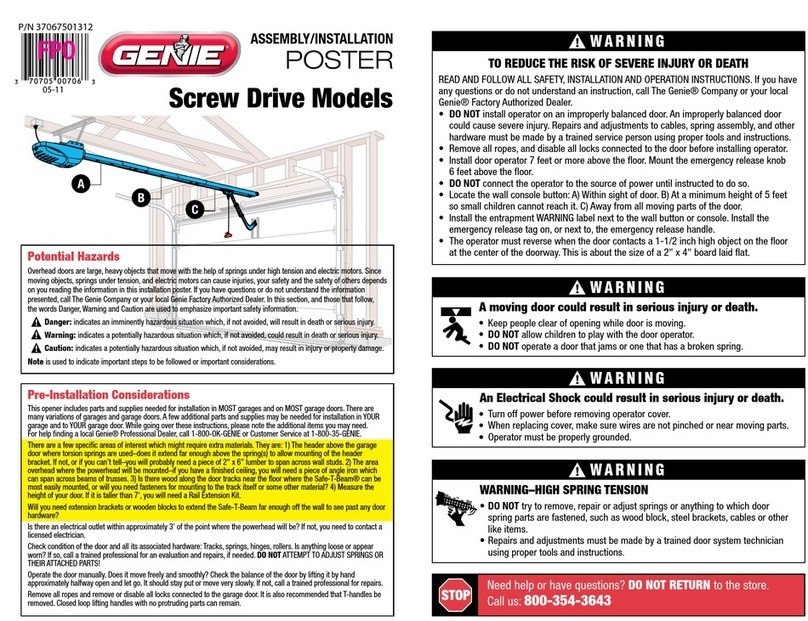

MOVINGDOOR

ELECTRICALSHOCK

HiGHSPRINGTENSION

EFFECT

WARNING:

Can Cause Serious

Injury or Death

WARNING:

Can Cause Serious

Injury or Death

WARNING:

Can Cause Serious

Injury or Death

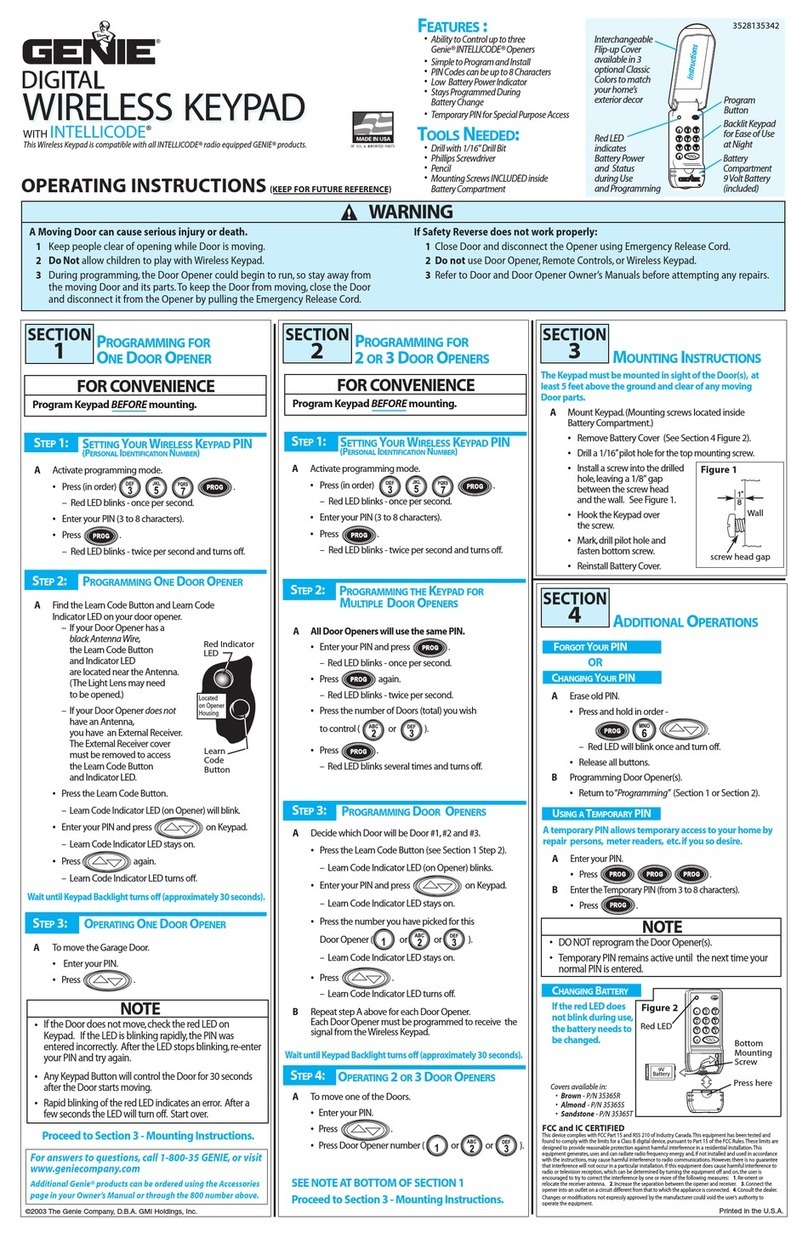

•Keep people clear of opening while door is moving.

•Do Not allow children to play with the door operator.

•Do Not operate a door that jams or one that has a broken spring.

•Turn off power before removing operator cover.

•Whep replacing cover, make sure wires are not pinched or near

mowng parts.

•Operator must be properly grounded.

•Do Not try to remove, repair or adjust springs or anythinqto

which door sprinq parts are fastened, such as,wood blocks,

steel brackets, caNes or other like items.

•Repairs and adjustments must be made by a trained service

person using proper tools and instructions.

WARNING:

TO REDUCETHE RISKOF SEVEREINJURYOR DEATH:

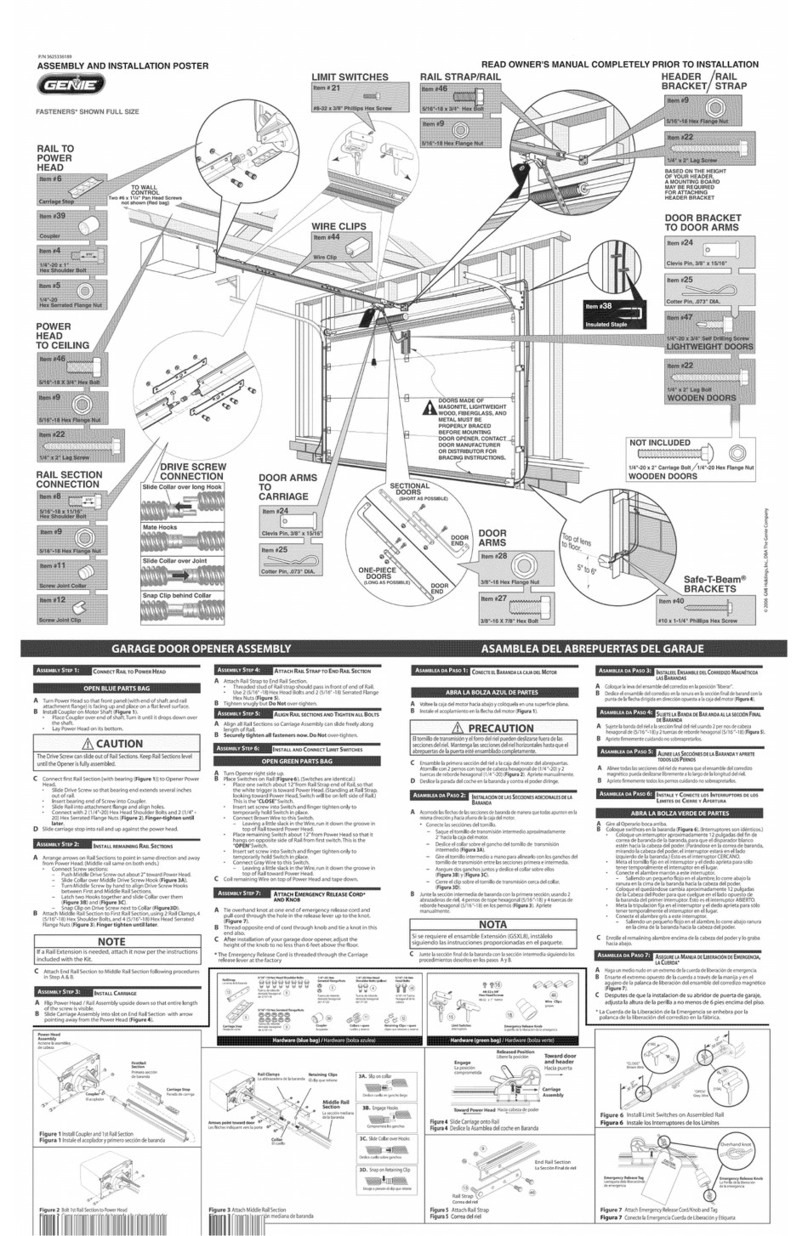

1 READAND FOLLOW ALL SAFETY,INSTALLATIONAND

OPERATIONINSTRUCTIONS.If you have any

questions or do not understand an instruction, call

your service representative.

2 Do Not install operator on an improperly balanced

door. An improperly balanced door could cause

severe injury. Repairs and adjustments to cables,

spring assembly, and other hardware must be made

by a trained service person using proper tools and

instructions.

3Remove all ropes, and disable all locks connected to

the door before installing operator.

4 Install door operator 7 feet or more above the floor.

Mount the emergency release knob 6 feet above

the floor.

5 Do Not connect the operator to the source of power

until instructed to do so.

6 Locate the control button:

• Within sightofdoor.

• At a minimum height of 5 feet, so small children

cannot reach it.

• Away from all moving parts of the door.

7 Install the entrapment WARNING label next to the

wall button or console. Install the emergency release

tag on, or next to, the emergency release

8 The operator must reverse when the door contacts a

1-1/2 inch his h object on the floor at the center of

the doorway.This is about the size of a 2 x 4 board

laid flat.

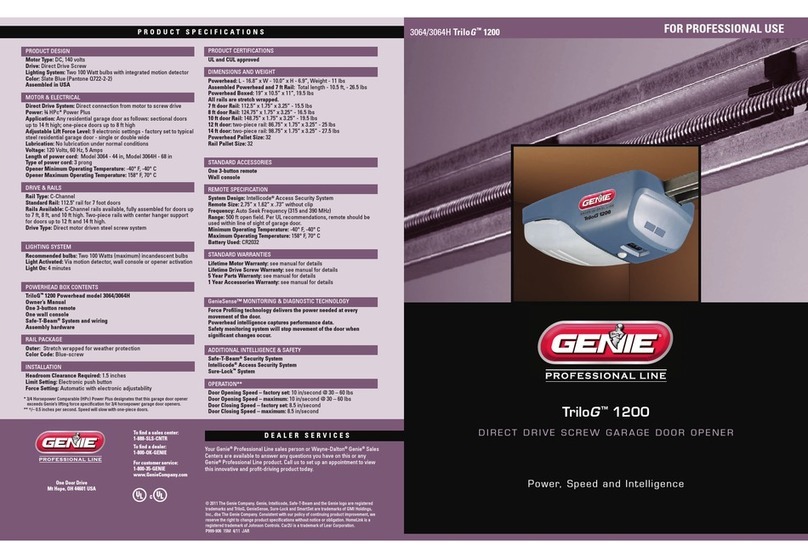

Safe-T-Beam® (STB)Non-Contact ReversingSystem

Places an invisible beam across door opening, that reverses

the door during down travel to the fully open position if

anything passesthrough beam.

Safe-T-Reverse®ContactReversingSystem

Automatically stops and reverses a closing door within 2

seconds of contact with an object.

Safe-T-Stop®Timed Reversed System

Automatically opens a closing door, if door does not close

within 30 seconds.

Force Guard ®Control

Used to set the force required for opening and closing

door. For maximum safety, set the minimum force required

to fully open and close door.

Automatic Lighting System

Two light bulbs up to 60 Watts max. each, are used for safer

entries and exits.The light turns on when door isactivated

and automatically turns off 4.5 minutes later.

Manual Emergency Release

Allows the garage door to be opened or closed manually

for emergencies or maintenance.