02

Disclaimer

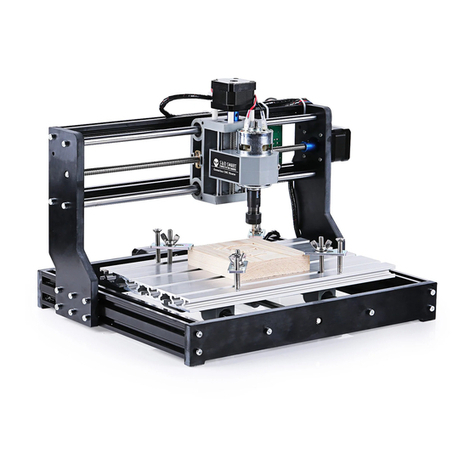

Please be careful when using your CNC machine.This machine is an electrical device with moving parts and

dangerous areas.

● Genmitsu CNC Machines are for Indoor Use Only.

● You must be 18 years or older to operate this machine, unless supervised by a knowledgeable adult familiar

with the machine.

● Wear the proper Personal Protection Equipment (Safety Glasses etc.).

● Always place the CNC Machine on a stable surface.

● The SainSmart Genmitsu CNC Machine is supplied with Switchable Power Supply 230VAC or 115VAC. Never

use a different power supply; it may cause malfunctions or damage to the machine.

● The PROVerXL 6050 Plus utilizes a high amp power supply. It is recommended that you do not plug the CNC

Router into an extension cord, or power strip as it may damage the machine.

● Ensure the Emergency stop button is easily accessible at all times.

● Never disassemble the Power Supply or Electrical Components. This will VOID the warranty.

● DO NOT TOUCH the machine spindle, or place any body part near the working area when the machine is

operating.Serious injury may oCcur.

● DO NOT leave children unsupervised with the CNC Machine even when it's not operating. Injury may occur.

● DO NOT leave the machine unattended while it's operating.

● Ensure your CNC Machine is in a well-ventilated area. Some Materials may discharge smoke or fumes during

operation.