NOTICE: ONLY IVORY® DISHWASHIN LIQUID IS TO BE USED. OTHER BRANDS

ARE NOT RECOMMENDED AND MAY CAUSE YOUR DETECTOR TO

MALFUNCTION.

6. Allow smoke detector to soak for approximately 10 minutes (longer if extremely

dirty). Then agitate for 5 or 10 seconds to flush out any remaining dirt left inside

detector's housing.

7. Remove detector from wash water and transfer directly to one of the first rinse

buckets containing clear water. Again, allowing smoke detector to become

completely submerged, agitate once more for 5 or 10 seconds to remove soap

residue.

8. Finally, transfer detector to your second and final rinse bucket, repeating method

found in Step 7, then remove smoke detector to a clean dry area for a period of 48

hours to allow it to thoroughly dry.

I PORTANT: It is recommended to change wash and rinse water after five (5) smoke

alarms. If your devices are extremely dirty, water should be changed more frequently.

NOTICE: SMOKE DETECTORS ARE TO AIR DRY ONLY. DO NOT PLACE SMOKE

DETECTOR IN OVEN OR USE A HOT AIR BLOWER TO ACCELERATE DRYIN

TIME. THIS COULD RESULT IN DAMA E TO YOUR SMOKE DETECTOR.

In the event you experience difficulty in the cleaning of your smoke detectors or if you

have any questions, please contact entex Corporation or your local entex distributor

If the smoke detector does not work properly, do not try and fix

it yourself. This will void your warranty. See "To Return a Smoke Detector" for

instructions to return smoke detectors that do not operate properly. DO NOT TRY

TO FIX IT YOURSELF.

I PORTANT: entex recommends smoke detectors be tested a minimum of once a

week.

Never use an open flame of any kind to test your smoke

detector. You may ignite and damage the smoke detector as well as the

surrounding area. The test feature of your smoke detector accurately simulates

smoke conditions and tests the smoke detector’s functions as required by

ANSI/UL 268.

Do not cover, tape, or otherwise block the openings of your

smoke alarm. These openings are designed to allow air to pass through your

smoke detector, thus sampling the air around the smoke detector.

Smoke detectors are not to be used with detector guards

unless the combination has been evaluated and found suitable for that purpose.

NOTICE: FAILURE TO RE ULARLY CLEAN THIS SMOKE DETECTOR MAY RESULT

IN NUISANCE ALARMS. A BUILD UP OF DUST CREATES AN OBSCURATION THAT

\SIMULATES SMOKE. THIS MEANS THE UNIT MAY O INTO ALARM WITHOUT A

SMOKE CONDITION.

TO RETURN A S OKE DETECTOR

Should you experience problems with your smoke detector, proceed as follows:

1. Turn off electrical power to the detector.

2. Rotate the detector counter-clockwise to remove it from its mounting plate.

3. Unplug the connector from the back of the detector. Do not remove the wire

connection; leave the connector for your replacement detector. If the system is to

remain active while the detector is removed, a jumper plug must be installed.

Contact factory for part.

4. Carefully pack (the manufacturer cannot be responsible for consequential damage)

and return to the manufacturer. Include complete details as to exact nature of

difficulties being experienced and date of installation.

5. Return to: entex Corporation, 10985 Chicago Drive, Zeeland, Michigan 49464.

RMA number from our return department.

LIMITED WARRA TY

For a period of 24 months from the date of purchase, or a maximum of 20 months from the date of manufacture,

Gentex warrants to you, the original consumer purchaser, that your Smoke Detector will be free from defects in

workmanship, materials, and construction under normal use and service. If a defect in workmanship, materials, or

construction should cause your Smoke Detector to become inoperable within the warranty period, Gentex will repair

your Smoke Detector or furnish you with a new or rebuilt replacement Smoke Detector without charge to you except

for postage required to return the Smoke Detector to us. Your repaired or replacement Smoke Detector will be

returned to you free of charge and it will be covered under this warranty for the balance of the warranty period.

This warranty is void if our inspection of your Smoke Detector shows that the damage or failure was caused by

abuse, misuse, abnormal usage, faulty installation, improper maintenance, or repairs other than those performed by

us. A Y WARRA TIES IMPLIED U DER A Y STATE LAW, I CLUDI G IMPLIED WARRA TIES OF

MERCHA TABILITY OR FIT ESS FOR A PARTICULAR PURPOSE, APPLY O LY FOR THE WARRA TY

PERIOD SPECIFIED ABOVE. PLEASE OTE THAT SOME STATES DO OT ALLOW LIMITATIO S O HOW

LO G A IMPLIED WARRA TY LASTS, SO THE ABOVE EXCLUSIO MAY OT APPLY TO YOU.

GE TEX WILL OT BE LIABLE FOR A Y LOSS, DAMAGE, I CIDE TAL OR CO SEQUE TIAL DAMAGES

OF A Y KI D ARISI G I CO ECTIO WITH THE SALES, USE OR REPAIR OF THIS SMOKE DETECTOR.

PLEASE OTE THAT SOME STATES DO OT ALLOW THE EXCLUSIO OR LIMITATIO OF I CIDE TAL OR

CO SEQUE TIAL DAMAGES, SO THE ABOVE EXCLUSIO MAY OT APPLY TO YOU.

If a defect in workmanship, materials, or construction should cause your Smoke Detector to become inoperable

within the warranty period, you must return the Smoke Detector to Gentex postage prepaid. You must also pack the

Smoke Detector to minimize the risk of it being damaged in transit. You must also enclose a return address. Smoke

Detectors returned for warranty service should be sent to: Gentex Corporation, 10985 Chicago Drive, Zeeland, MI

49464.

If we receive a Smoke Detector in a damaged condition as the result of shipping, we will notify you and you must

file a claim with the Shipper.

THIS LIMITED WARRA TY GIVES YOU SPECIFIC LEGAL RIGHTS. YOU MAY ALSO HAVE OTHER RIGHTS

WHICH VARY FROM STATE TO STATE.

GE TEX CORPORATIO

10985 CHICAGO DRIVE, ZEELA D, MI 49464

PHO E: 1-800-436-8391

www.gentex.com

550-139-LAC 9-29-97

Important otice:

These materials have been prepared by Gentex Corporation ("Gentex") for informational purposes only, are necessarily summary, and are not purported to serve as legal advice and should not be used as such. Gentex makes no representations and warranties, express or implied, that these

materials are complete and accurate, up-to-date, or in compliance with all relevant local, state and federal laws, regulations and rules. The materials do not address all legal considerations as there is inevitable uncertainty regarding interpretation of laws, regulations and rules and the application of

such laws, regulations and rules to particular fact patterns. Each person's activities can differently affect the obligations that exist under applicable laws, regulations or rules. Therefore, these materials should be used only for informational purposes and should not be used as a substitute for seeking

professional legal advice. Gentex will not be responsible for any action or failure to act in reliance upon the information contained in this material.

Pg. 8-4

e. The test knob is not an electrical switch, nor is it connected in any way to the

alarm horn. Therefore, when you test with the test knob, you are simulating the

smoke condition in the detector and testing all elements of the smoke detector

that are necessary for the detection of actual smoke. To check for proper smoke

entry into your smoke detector's sensing chamber, entex recommends using the

Home Safeguard Smoke Detector spray or CHEKKIT® SMOKE Detector Tester

from SDI. This test should be performed once a year and should be sprayed from

a distance no closer than 12 inches from smoke detector (refer to NFPA 72 for

details).

3. A trouble buzzer will sound if any detector is removed from its socket in supervised

circuits. CAUTION: When a smoke detector is removed it may cause other smoke

detectors to have a loss of power and become inoperative. If this happens,

reconnect the smoke detector until a replacement can be installed, or use a jumper

plug which can be ordered separately from the factory.

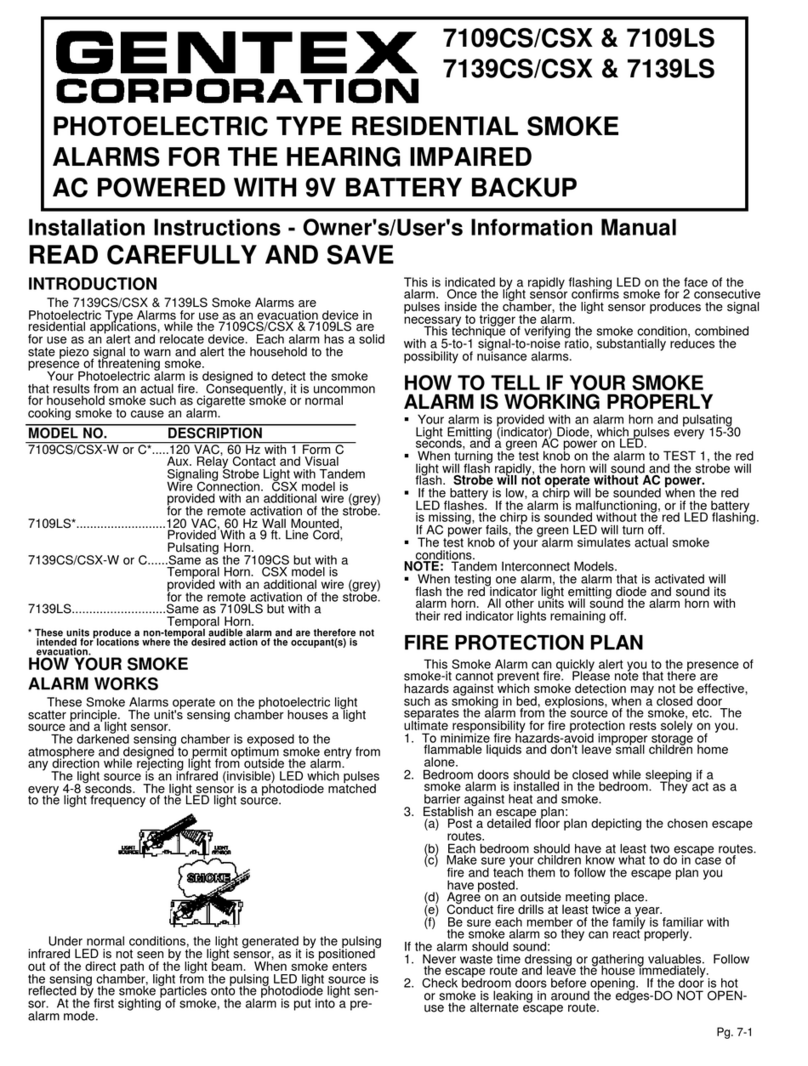

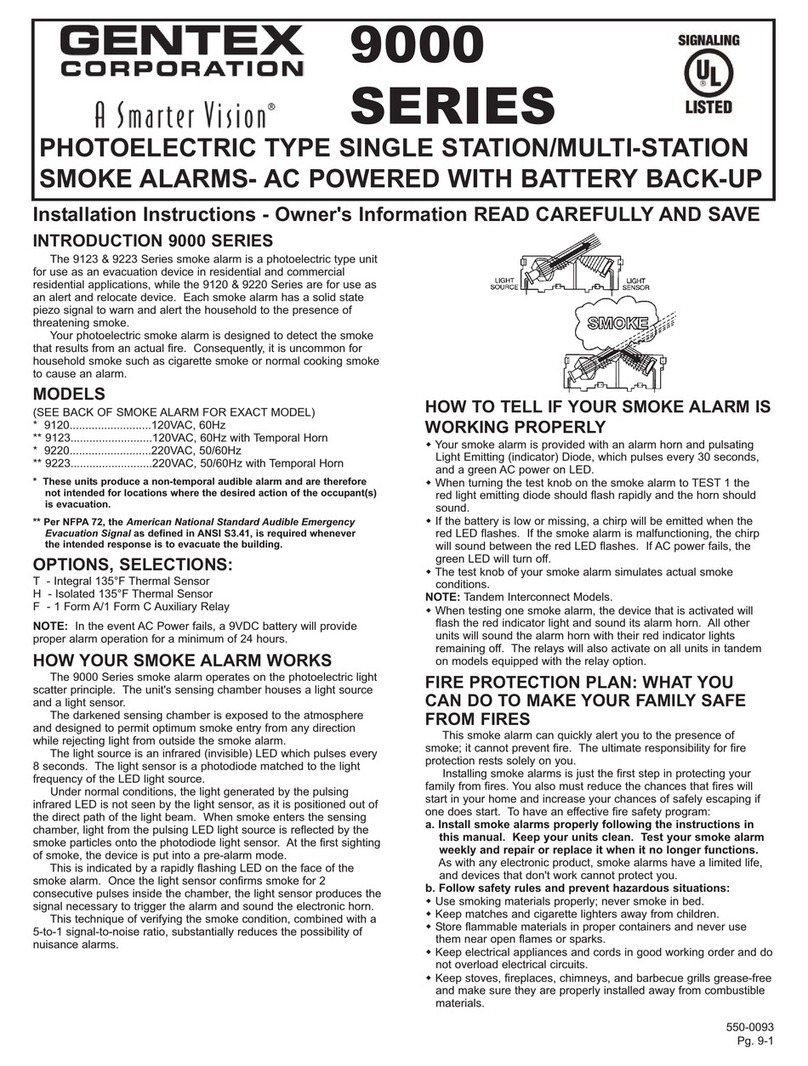

4. Power-On- Alarm Light. The LED on the face of the smoke detector blinks every

15-30 seconds, indicating electrical power is being supplied, see FI URE I. If the

smoke (or test knob) persists for about 20 seconds, the LED will be on continuously

for latching models or flash rapidly for non-latching models to indicate the alarm

condition of the smoke detector. It will stay on until the system is reset.

AINTENANCE

After your smoke detector has been in operation for a period of time or if it was

installed prior to the completion of all building construction, your smoke detector may

have become more sensitive due to dirt build-up in the smoke detector's optic sensing

chamber. This could cause nuisance alarms or cause the smoke detector to activate

from small amounts of smoke build-up. If this should occur, following this simple

washing procedure will restore your smoke detector back to its original condition.

For further information regarding frequency of maintenance and testing, refer to

NFPA 72, NFPA, Batterymarch Park, Quincy, MA 02269.

NOTICE: FAILURE TO FOLLOW FULL CLEANIN INSTRUCTIONS COULD

RESULT IN DAMA E TO THIS SMOKE DETECTOR.

1. Turn off electrical power to the detector.

2. Twist the smoke detector counter-clockwise to remove it from its mounting plate.

The fire alarm system shall remain active during all

maintenance. Therefore, while servicing one smoke detector, either use a

replacement smoke detector or jumper plug to keep the fire alarm system

operative. Contact your local Gentex distributor for the proper jumper plugs to

use with your fire system.

3. Unplug the connector from the back of the smoke detector. Do not remove the wire

connection; leave the connector for your replacement smoke detector or jumper plug.

4. Select three (3) standard size wash buckets and fill them each with one gallon of

normal tap water (distilled or de-ionized treated water is recommended as a final

rinse if water is extremely hard in your area).

5. Add 1/8 cup of Ivory® dishwashing liquid to the first bucket of water and allow it to

mix thoroughly, then place dirty smoke detector in the soap water mixture until it

becomes completely covered or submerged. NOTE: If the smoke detectors are

exceptionally dirty, you may wish to first wipe off any excess dirt before washing

smoke detector so as not to dirty the wash water too quickly.

DO NOT open smoke alarm for cleaning. IF S OKE ALAR IS

OPENED DURING CLEANING, PRODUCT WARRANTY BECO ES VOID.

FI URE I