−3−

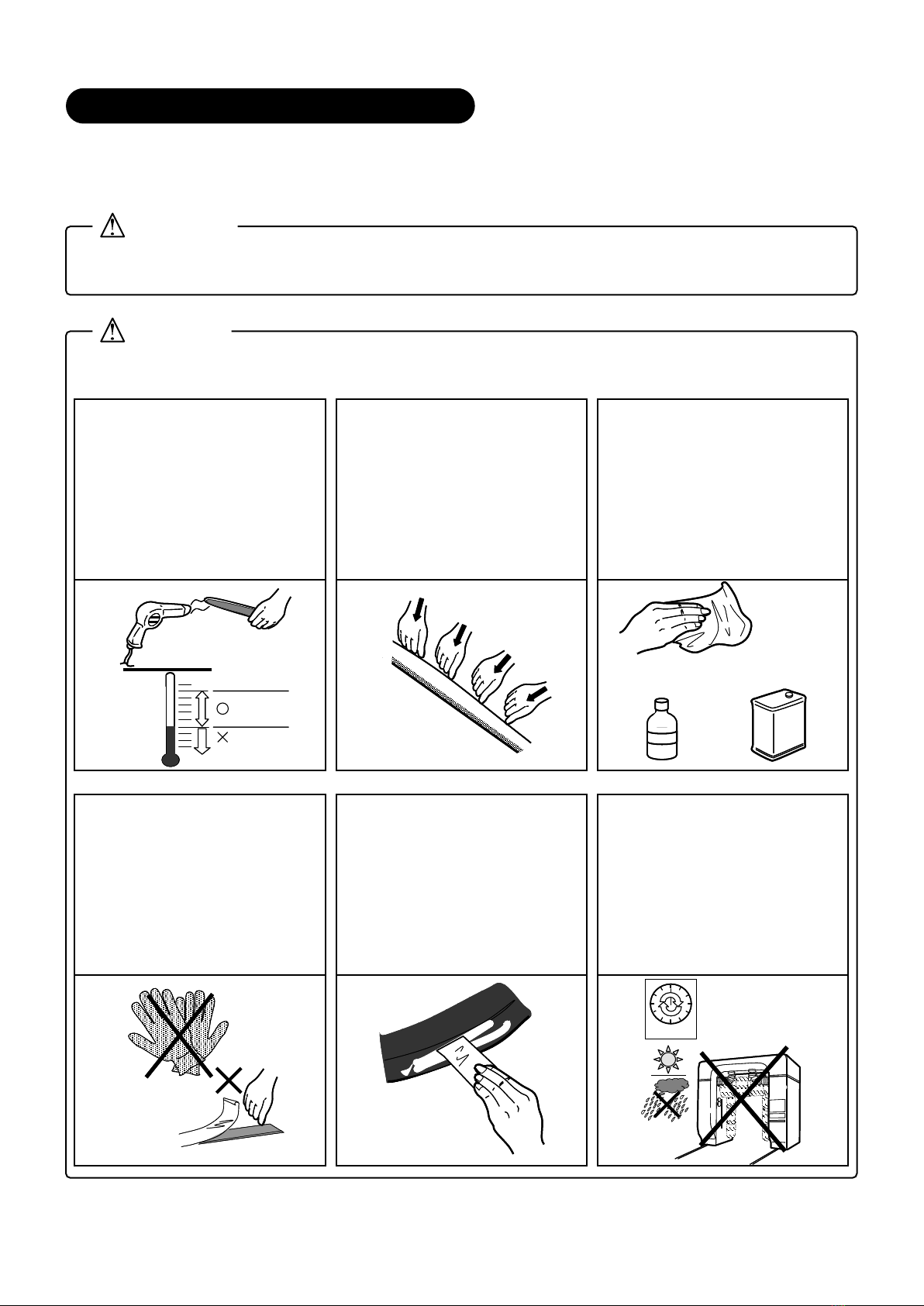

3.Check points before mounting

How to deal with a double‑stick tape

Used tools ☆Waste cloth ☆Masking tape ☆Primer☆Dryer or Infrared lamp

☆Cleaner [IPA (Isopropyl alcohol) or White gasoline or Hexane]

1. Atmosphere temperature 2.Stick firmly 3.Cleaning the adherend

4. Keep the tape away off

the stain. 6. Treatment after sticking

35℃(95°F)

15℃(59°F)

IPA

(Isopropyl alcohol) White gasoline

24 Hours

*An adherent indicates a door or a bumper,

parts are supplies materials.

・Park the car on a flat place, pull the handbrake well, set the stopper and start mounting.

If the car moves, it causes injuries.

Warning

Caution

Stickiness of an adhesive which keeps

off under 15℃is influenced by a resin

softness.Low temperature (under 15

℃) decrease firm stickiness and

lowers the sticking power.

When mounting it under the

atmosphere temperature, 15℃, warm

the a adherend and parts with a dryer

or an infrared lamp firmly.

Do not touch the adherend surface by

hand while working, or oil of grimy

hands sticks on the adherend.That

may cause lower the sticking power of

the double-stick tape.

In addition, do not stick any hair or

stain of the work gloves while working

with work gloves on.

To keep the adhered surface of the

double-stick tape fully, press the

adhered surface to the adherend

evenly.

Bond and press firmly the curved

edge of the double-stick tape or the

curbed adherend.

The sticking power is unstable within

24 hours after sticking.

Do not drive and wash the car within

24 hours and do not leave the car in

the rain.

Be sure not to stick again after

bonding and pressing the product.

That may cause lower the sticking

power extremely.

As for resin (material, uncoated)

adherend or glass, the surface treatment

with a primer is necessary to gain

adhesive power to be well attached onto

adherend surfaces. For a primer

treatment, perform a masking process no

to grease any other adherend surface of

the double-stick tape.

A stain, dust, or oil is subject to stick

on the double-side tape.That may

cause lower the sticking power of the

double-side tape.

Before sticking the tape, be sure to

clean the adherend surface with IPA

(isopropyl alcohol) or a white gasoline.

5. Surface treatment

with a primer