True View 600 Series Hardware User Guide

2 True View 600 Series Hardware User Guide 10/26/2021

Contents

About GeoCue Group, Inc. ......................................................................................................................4

About True View® 600 Series.................................................................................................................. 5

A True View Cycle ................................................................................................................................... 5

True View Hardware Integration Kit (M600)............................................................................................6

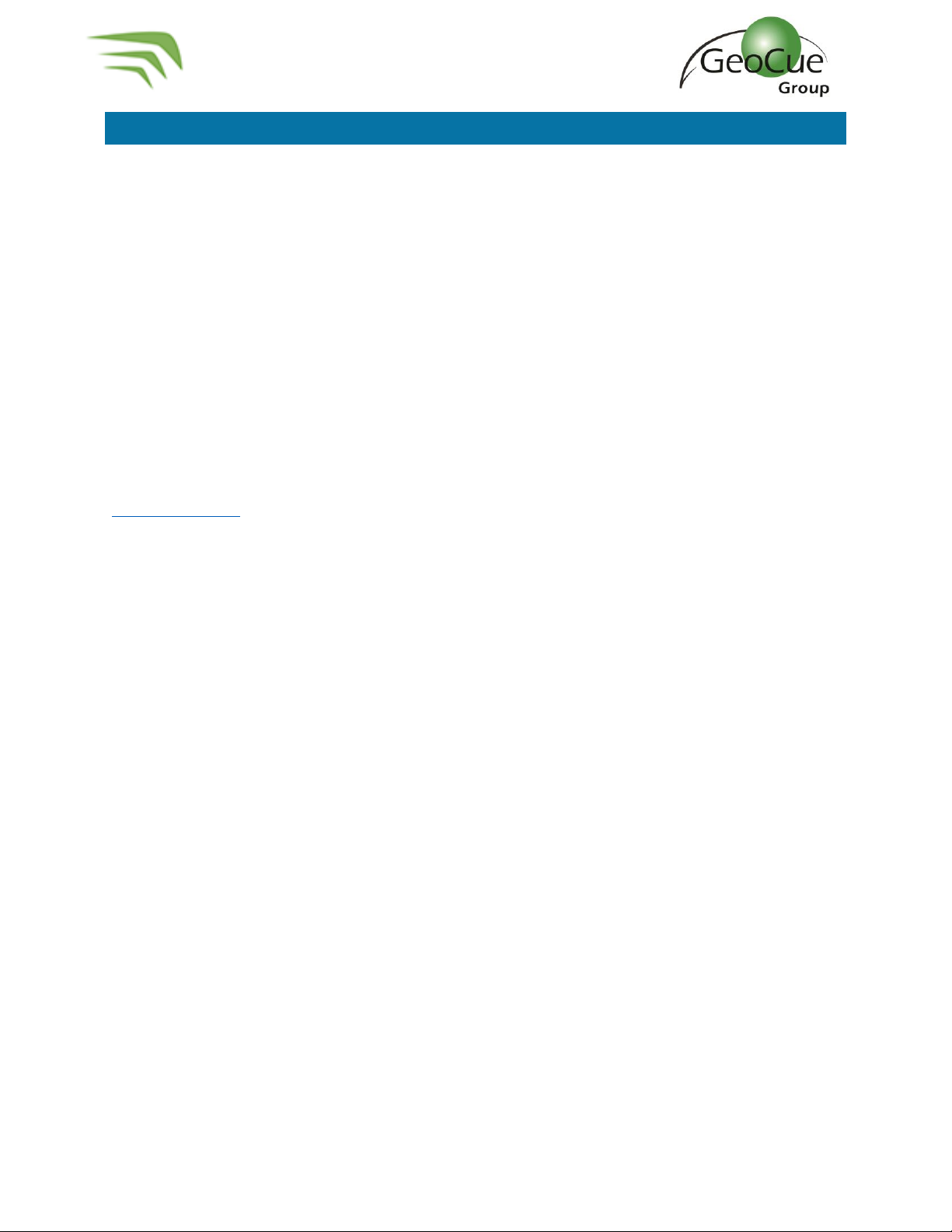

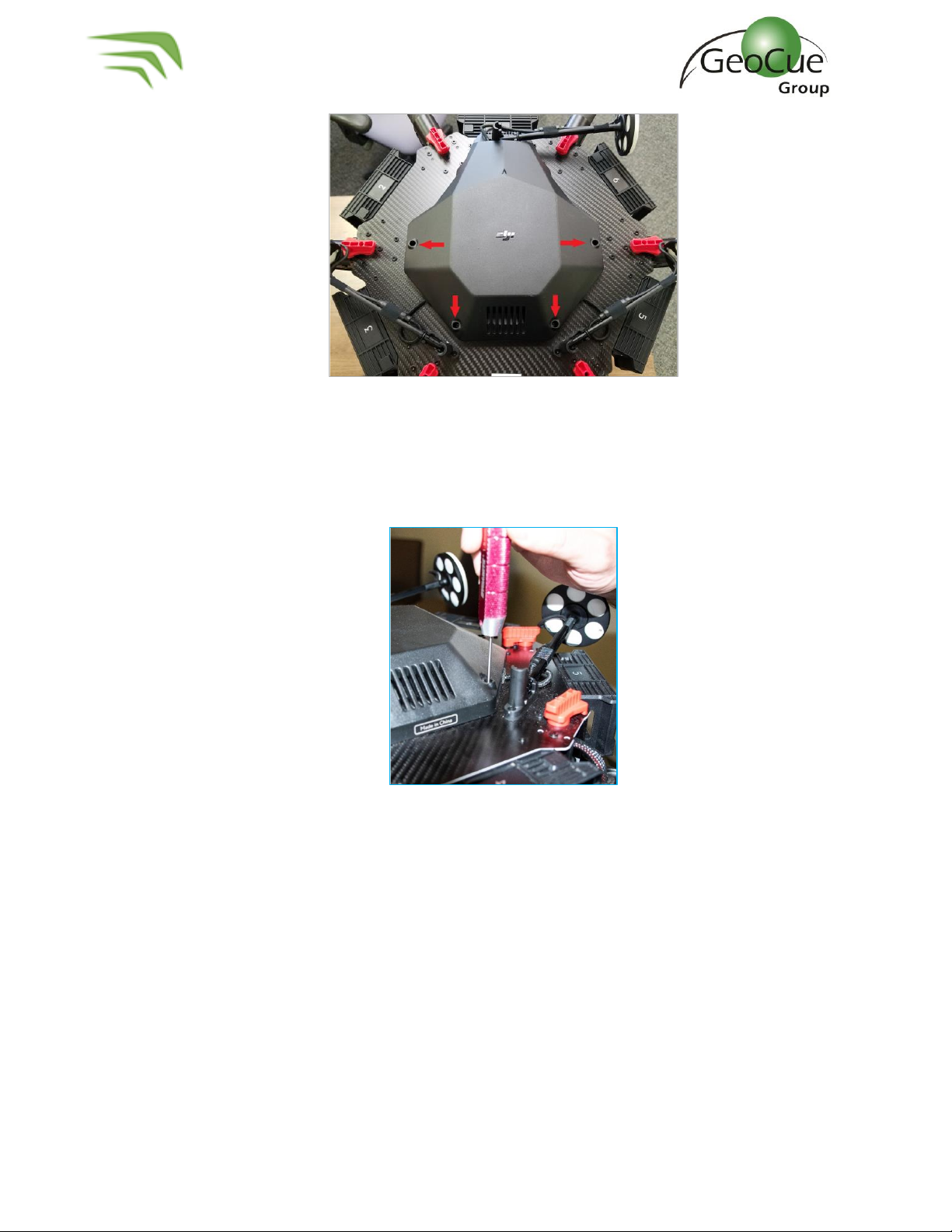

Installing the Top Plate and Controller Box .........................................................................................6

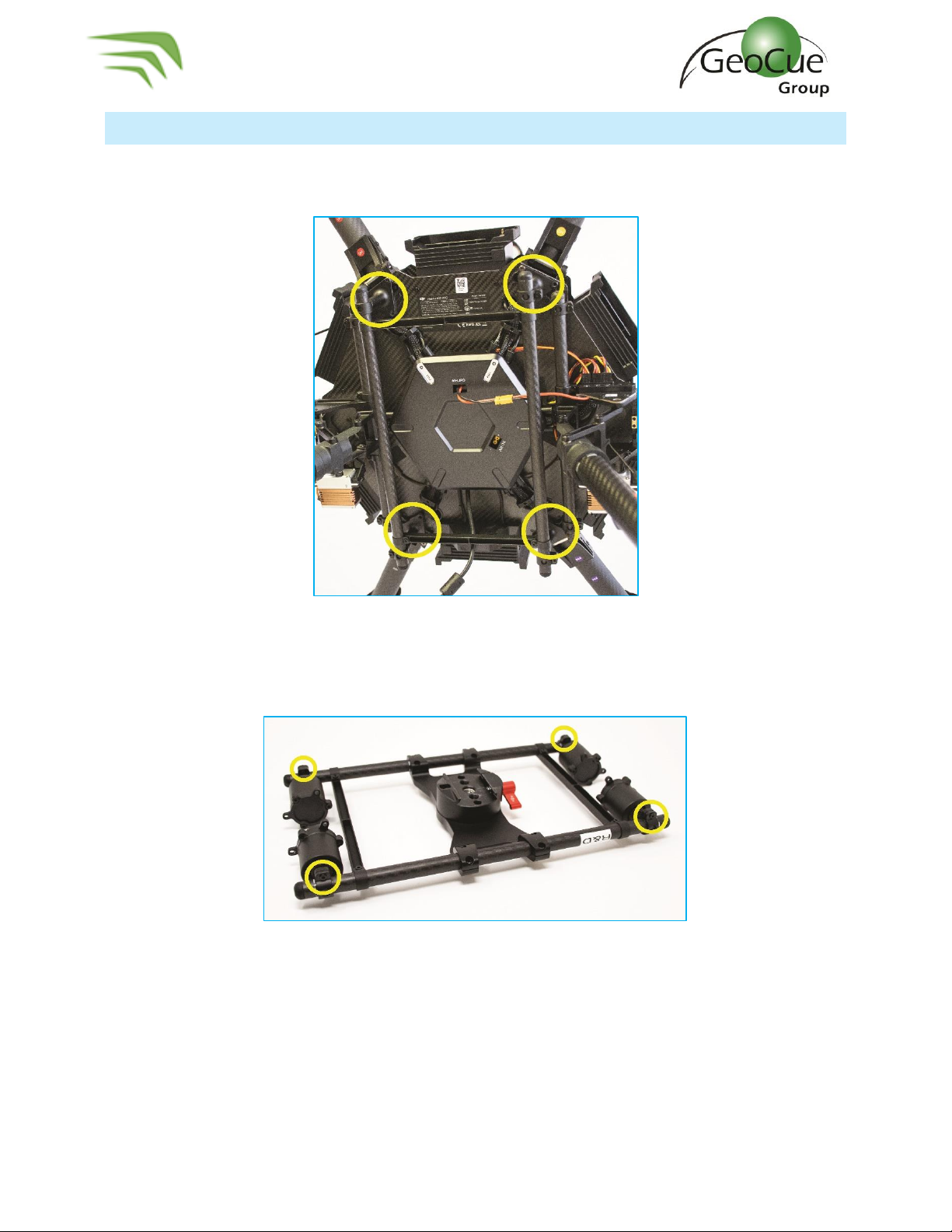

Installing the Ronin Mount ................................................................................................................ 10

True View 600 Series Installation .......................................................................................................... 12

True View Battery ................................................................................................................................. 16

True View Data Storage Devices............................................................................................................17

UMS...................................................................................................................................................17

Camera SD Cards ...............................................................................................................................17

System Configuration File (SCF)........................................................................................................ 18

Core Configuration File (CCF)............................................................................................................ 18

CCFSection6 –POS ....................................................................................................................... 18

CCFSection8 –Camera.................................................................................................................. 19

CCFSection11 –Configuration Laser..............................................................................................20

CCFSection15 –Battery................................................................................................................. 21

CCFSection16 - Cycle ....................................................................................................................22

CCFSection17 –Storage Auto Delete ............................................................................................ 23

True View 600 Series Field Operations..................................................................................................24

1. Base Station ..............................................................................................................................24

2. Pre-Flight .................................................................................................................................. 25

3. Controller Box LEDs .................................................................................................................. 27

4. Heading Alignment Maneuver...................................................................................................29

5. After Landing ............................................................................................................................ 30

True View EVO...................................................................................................................................... 31

Logging in To APX15............................................................................................................................. 32

Configure True View Wi-fi ................................................................................................................. 32

Log in to APX-15 ............................................................................................................................... 33

Download T04 Files....................................................................................................................... 33