TABLE of CONTENTS

1. OVERVIEW .........................................................................................................................................................1

2. HARDWARE........................................................................................................................................................1

3. INSTALLATION....................................................................................................................................................2

3.1 TURNING ON POWER................................................................................................................................................2

3.2 EARTH GROUND ......................................................................................................................................................3

3.3 GAGES ...................................................................................................................................................................3

3.4 COMMUNICATIONS ..................................................................................................................................................3

4. SOFTWARE .........................................................................................................................................................3

5. BATTERY MAINTENANCE....................................................................................................................................4

5.1 AC POWER .............................................................................................................................................................4

5.2 SOLAR POWER.........................................................................................................................................................4

5.3 EXTERNAL BATTERY ..................................................................................................................................................4

5.4 BATTERY REPLACEMENT ............................................................................................................................................4

5.5 FUSES ....................................................................................................................................................................4

6. TROUBLESHOOTING ...........................................................................................................................................5

APPENDIX A. SPECIFICATIONS ................................................................................................................................7

A.1 CR800 MEASUREMENT AND CONTROL MODULE ..........................................................................................................7

A.1.1 Analog Inputs..............................................................................................................................................7

A.1.2 Excitation Outputs ......................................................................................................................................7

A.1.3 Pulse Inputs.................................................................................................................................................7

A.1.4 Control Ports ...............................................................................................................................................8

A.2 AVW200 VIBRATING WIRE INTERFACE (SEE AVW200 MANUAL FOR COMPLETE SPECIFICATIONS) ........................................8

A.3 MODEL 8032 MULTIPLEXER (SEE THE APPENDIX FCOMPLETE SPECIFICATIONS)...................................................................8

APPENDIX B. SHIP LIST ...........................................................................................................................................8

APPENDIX C. DATA STORAGE .................................................................................................................................9

C.1 INPUT LOCATIONS ....................................................................................................................................................9

C.2 DATA STORAGE .......................................................................................................................................................9

C.3 DATA STORAGE EXAMPLE........................................................................................................................................10

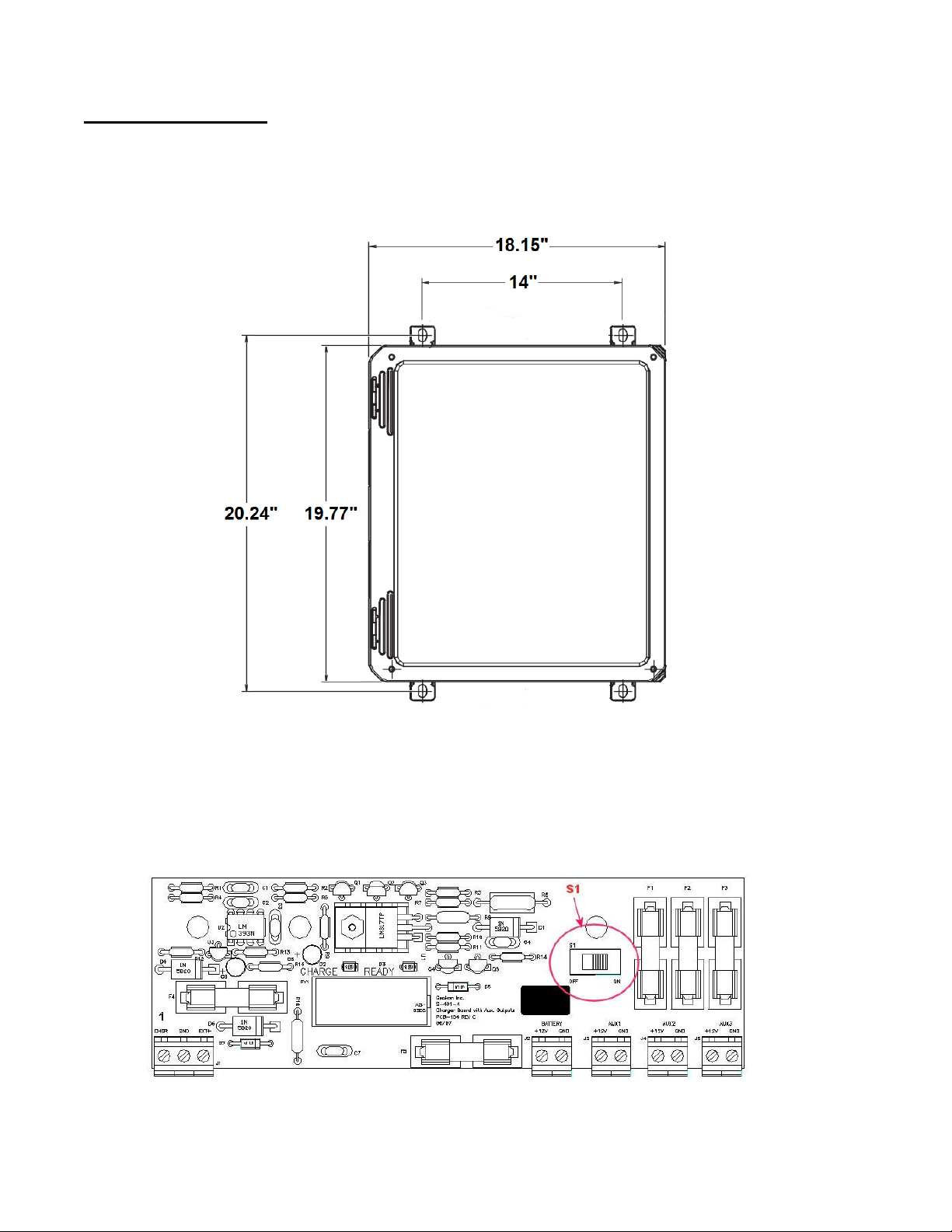

APPENDIX D. SYSTEM WIRING ............................................................................................................................. 11

D.1 CR800 WIRING (8025-2, 8025-3 AND 8025-4) ......................................................................................................11

D.2 AVW200 WIRING (8025-2, 8025-3 AND 8025-4) ..................................................................................................11

D.3. CR800 WIRING (8025-5).....................................................................................................................................11

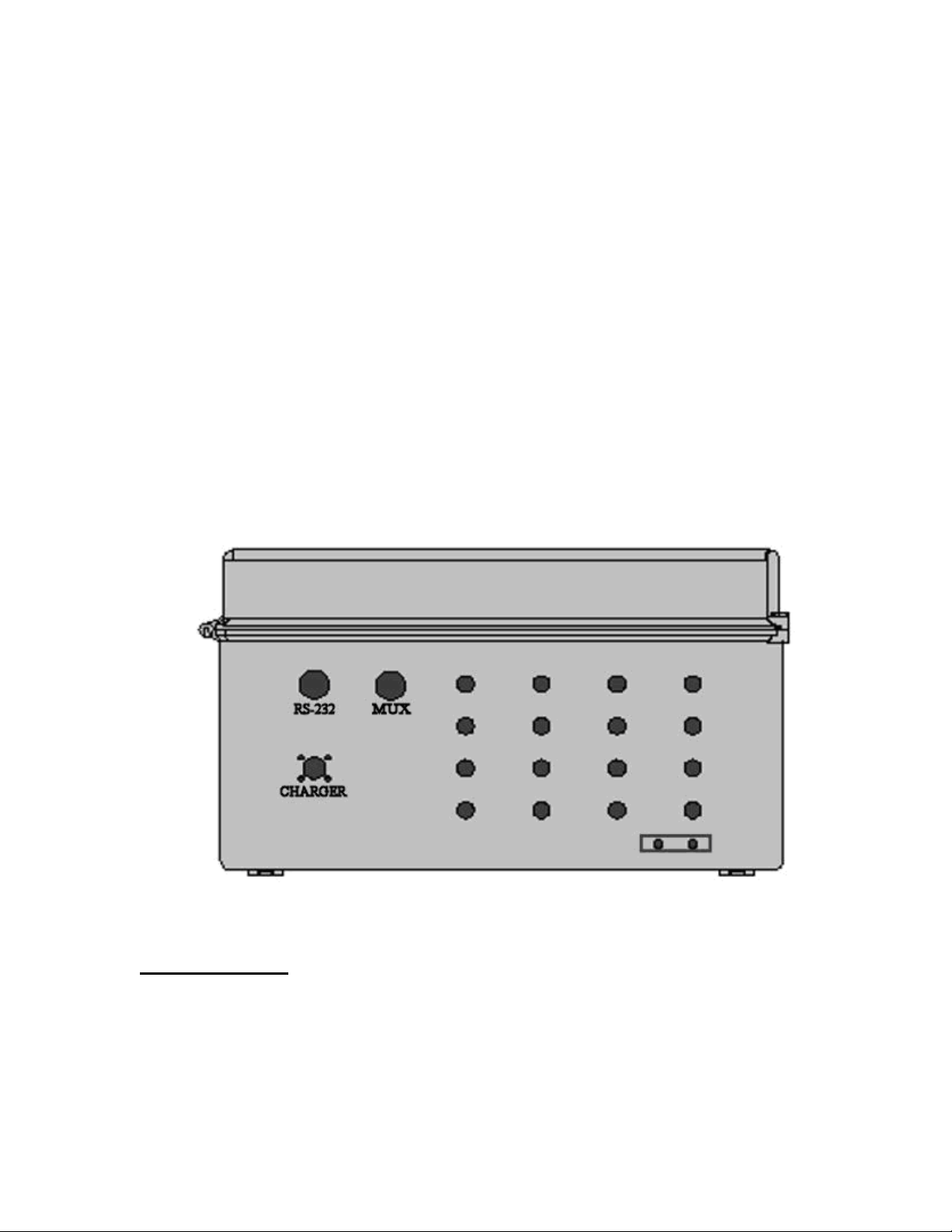

D.4 RS-232 CONNECTOR WIRING .................................................................................................................................12

D.5 CHARGER WIRING .................................................................................................................................................12

D.6 CABLES ................................................................................................................................................................12

D.6.1 AC Charger (110VAC/220VAC)..................................................................................................................12

D.6.2 External Power Cable................................................................................................................................12

D.7 FUSES..................................................................................................................................................................13

D.8 MULTIPLEXER CONNECTOR WIRING ..........................................................................................................................13