3

Table of content

1.0 General safety precautions . . . . . . . . . . . . . . . . . . 3

1.1 Danger ..................................3

1.2 Field of application . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Handling ................................3

1.4 Technical data.............................3

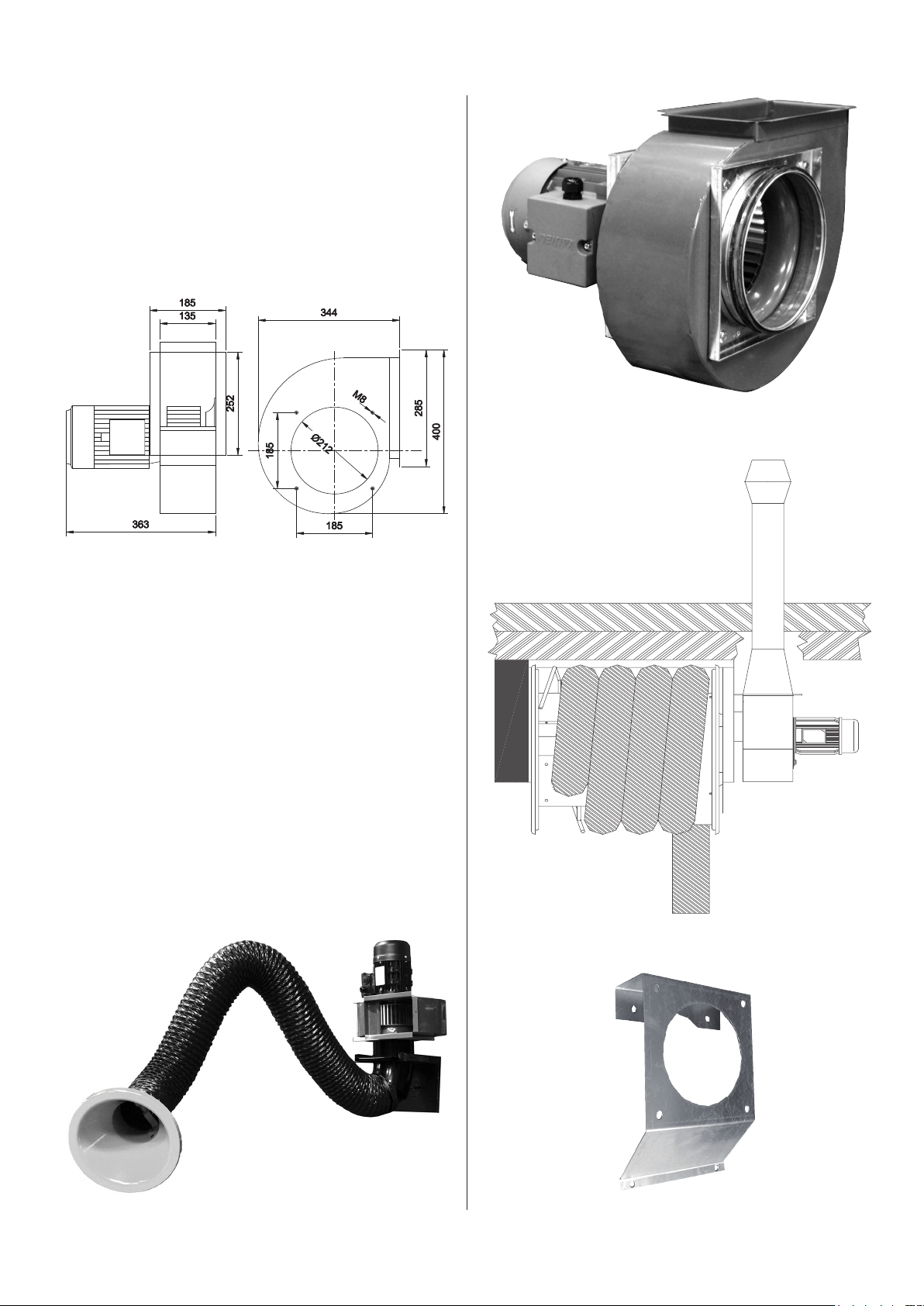

1.5 Construction .............................4

2.0 Installation ...............................4

2.1 Fitting accessories .........................5

2.2 Trial run - adjustment .......................5

3.0 User instruction - application .................5

4.0 Maintenance..............................5

4.1 Trouble shooting ...........................5

5.0 Liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5.1 Disposal .................................6

5.2 Environmental impact.......................6

6.0 Declaration of conformity ....................7

1.0 General safety precautions

IMPORTANT - Please study all the instructions before

mounting and commissioning.

Please keep these instructions in a safe place and

instruct all users in the function and operation of the

product.

Do not dismantle any factory-mounted parts, since it

impedes the commissioning of the equipment.

All electrical installations must be carried out by an

authorised electrician.

1.1 Danger

Mounting must be completed before conneting and

using the fan.

Removing the protection net on the fan whilst in opera-

tion involves risk of mutilation.

Always switch o the current when mounting something

on the fan or when servicing it.

1.2 Field of Application

The Fan MSQ is applied for process extraction within

the industry for the extraction of welding smoke,

exhaust gasses, grinding dust and vapours.

The Fan is not suitable for the extraction of aluminium

dust, our, textile dust nor for sawdust or other media,

which are connected with danger of explosion, without

specic approval from Geovent A/S.

1.3 Handling

Aleays use gloves when handling the fan.

The fan should be lifted by using one hand under the

motor and one under the casing.

1.4 Technical data

Temperature

Temperature extracted air Max 80 °C

Temperature ambient. Max 40 °C

For use at higher temperatures, use special motors.

Please enquire at Geovent.

Noise

The sound level depends on various factors under

various circumstances. For instance, where in the room

the Fan has been installed, the size of the room, the

temperature in the room, the accoustic prole of the

room and also the connection (hose><pipe) of the fan

inuences the sound level of the fan.

The actual ampere consumption and the kW of the

motor are shown on the metal sign on the Fan

Pressure drop

150

500

Airflow [m³/h]

Ventilator MSQ-200

1000 1500 2000 2500 3000 3500 4000 4500 5000 5500

300

450

600

750

900

1050

1300

1450

1600

1750

200

Tryktab [Pa]

Type Lp, dB(A) Lp, 1m

MSQ-200 78 72