4

Motor: B5 flange motor, directly driven. Protection class

IP 54.

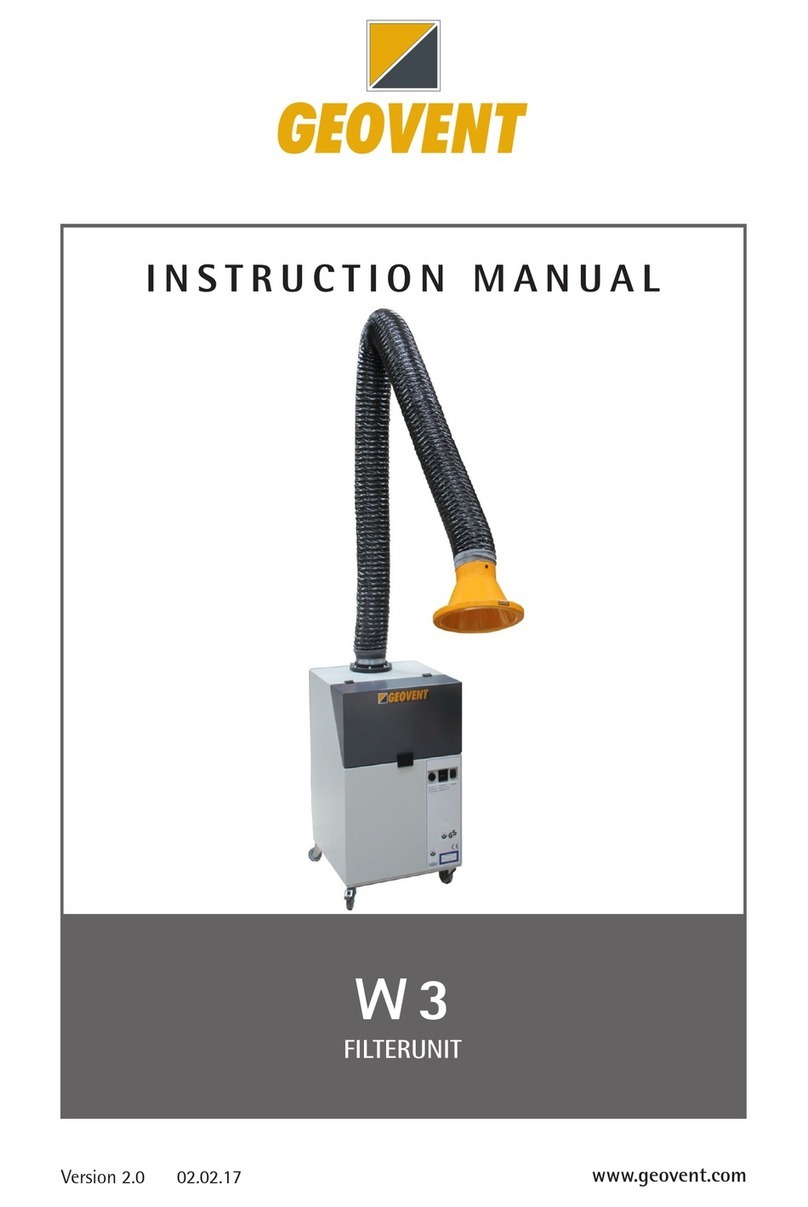

The unit is polyester coated, RAL 1007

Hose/hood: 2x5m ø125mm or ø160mm flexible and

light, hose with flexible connection for easy mounting

and dismounting. Epoxy coated suction hood with mag-

net for fixation. RAL 1007.

Cable: 10m rubber cable.

Switch On/Off switch with build in thermal fuse 10A.

2.0 Installation

Avoid bending of the hose immediately before the inlet

or the outlet, as this may reduce the efficiency of the

fan.

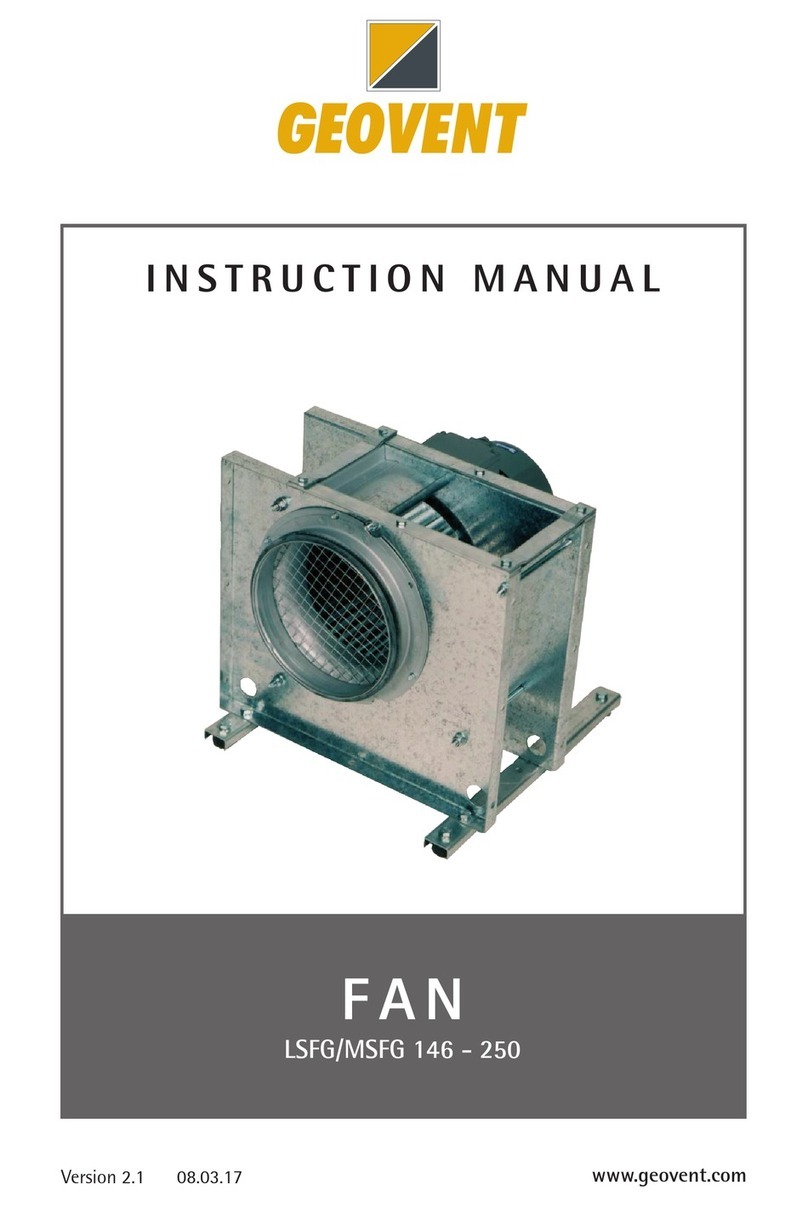

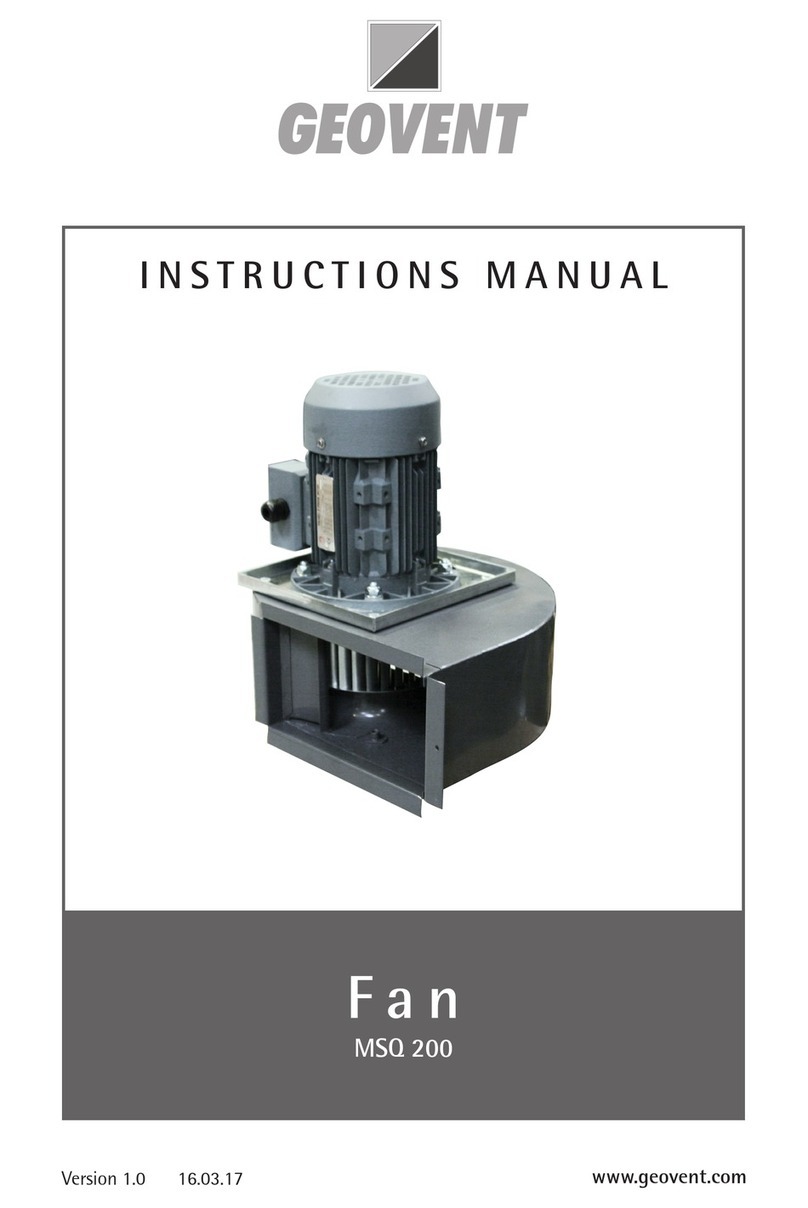

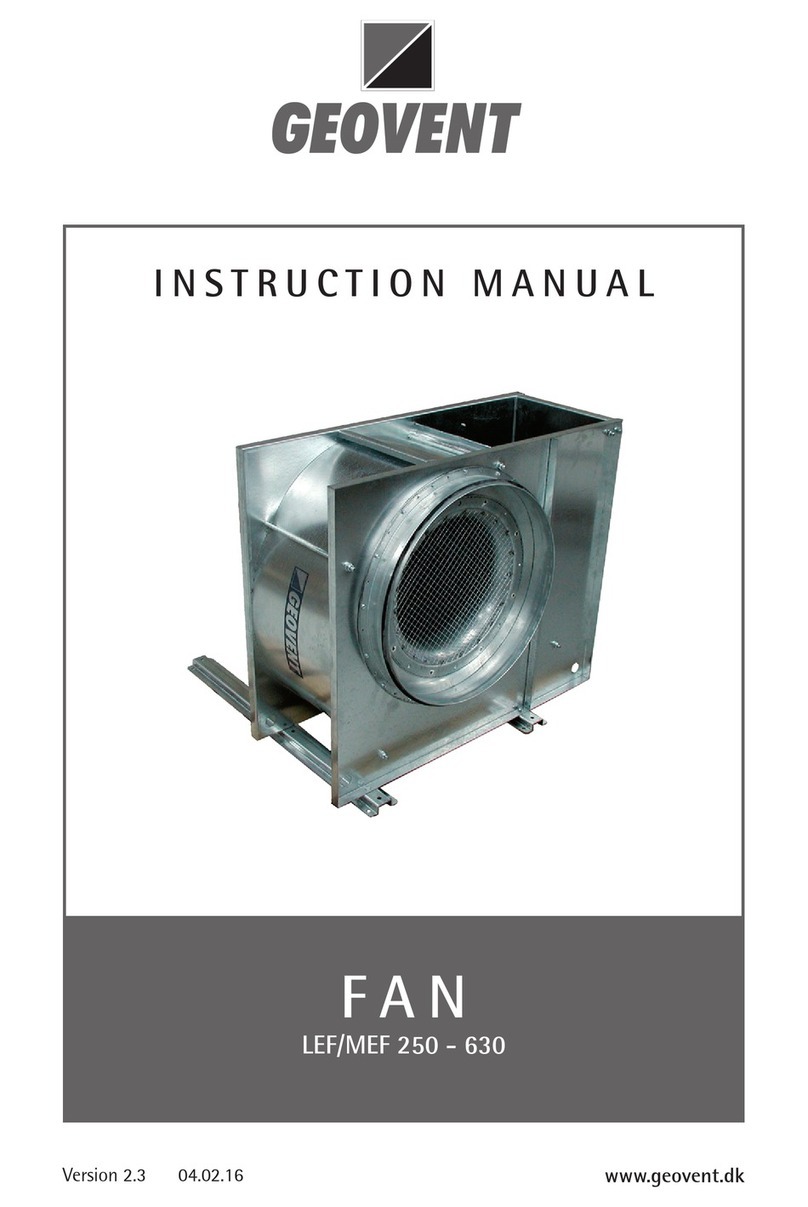

The fan is supplied in complete/assembled condition,

ready for connection to piping and to the mains.

If at all possible, please avoid bends just before the inta-

ke and after the outlet, since otherwise this would redu-

ce the yield of the fan.

Connection of the fan to the mains:

1. The fan should be connected to 1x230V 50Hz, as

standard.

2. Circuit diagram 1-phase motor (nonadjustable).

Should only be changed by qualified electrician, in

case the direction of the impeller is wrong.

3.0 User instruction – application

When extracting large quantities of air containing dust,

the fan wheel may get out of balance due to dirt on the

wheel.

In many cases, the fan is started by pushing the green

button on the motor protection switch (if automatics are

not used).

The fan does not work according to the purposes, if …

- unauthorised parts have been mounted on the fan (e.g.

unauthorised wheel).

- the wheel runs in the wrong direction. It will still work,

but the capacity will be reduced to a third of the normal

capacity.

- no motor protection switch is used.

4.0 Maintenance

Periodic maintenance

• In principle, the motor is free of maintenance because

of the factory-mounted, completely closed special ball

bearings. Exchange of worn bearings should only be

handled by an electrician.

• The wheel and the fan housing should be cleaned once

a year or according to requirement. The wheel and the

housing may be cleaned by means of a washing-up

brush and a dishwater. Remember to disconnect the

power before the washing. Afterwards wipe the parts

with a dry cloth. This results in a longer life of the fan.

4.1 Trouble-shooting

In case of problems with the fan, the following items may

be reviewed:

The volume of air or the pressure is below the

stated level:

• Wrong direction of the wheel.

May be due to wrong electrical installation. Please

double-check the direction of the rotation. Change two

phases, if necessary.

• Leaky hose/flanges.

• Bending hose inlet/outlet possibilities near the fan may

reduce the yield (e.g. 90° bend before the inlet).

• Damaged wheel.

• If the temperature deviates substantially from the lab

measurements, where the temperature was 20°C with

an atmospheric pressure of 101.4 kPa.

• The suction net has been blocked by cotton waste, a

cloth, or the like.

1

0

420300

350

Circuit breaker/termosikring 5A

ON/OFF switch - Tænd/sluk knap

Handle/Håndtag

Vibrationpads/vibrationsdæmpere

10 m cable/10m gummikabel

Outlet/Afkast ø125/150/160 mm

Inlet/Indtag ø125/150/160 mm