Contents

1 Safety........................................................................ 3

1.1. Application as directed.......................................................................... 3

1.2. Safety instructions ................................................................................ 3

1.3. Work bench / Authorized user .............................................................. 3

2 Technical description.............................................. 4

2.1. Warranty conditions .............................................................................. 4

2.2. Technical data....................................................................................... 4

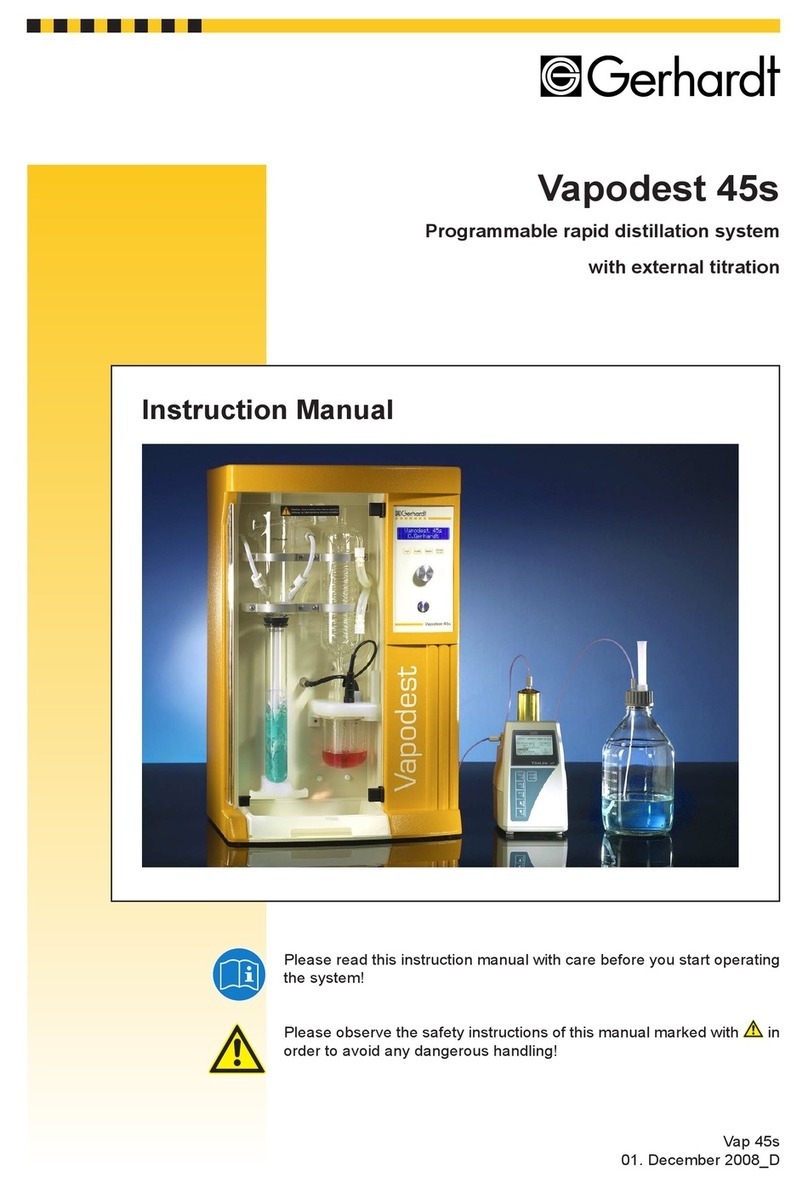

3 Description of the system ...................................... 5

3.1. Check for transport damage ................................................................. 5

3.2. Parts list................................................................................................ 5

3.3. Front view ............................................................................................. 6

3.4. Rear view.............................................................................................. 7

4 Assembly and setting into operation .................... 8

4.1. General................................................................................................. 8

4.2. Tubing connections............................................................................... 8

4.3. Mains connection.................................................................................. 9

4.4. Setting into operation............................................................................ 9

5 Operation ............................................................... 10

5.1. Keyboard ............................................................................................ 10

5.2. Setting of timer ................................................................................... 10

5.3. Priming the tubes................................................................................ 11

5.4. Test run............................................................................................... 11

5.5. Distilling a sample............................................................................... 12

6 Errors...................................................................... 13

6.1. Distillation does not start or is interrupted .......................................... 13

6.2. Results too high.................................................................................. 13

6.3. Results too low or no results .............................................................. 14

7 Maintenance........................................................... 15

7.1. Spare parts and accessories .............................................................. 15

7.2. Service and cleaning ......................................................................... 15

7.2.1. Cleaning the glass parts .................................................................. 16

7.2.2. Cleaning the steam generator ......................................................... 16

7.3. Trouble shooting / Contact the Service department ........................... 16

7.4. Disposal.............................................................................................. 17