12

A0Flashing light 01x No pre-warning, static output

02 With pre-warning, static output

1Garage light time 0...5.0...903 59= 59 sec.; 2.5= 2 min. 50 sec., etc

2Gate speed 01...903 01: minimum speed (40Hz);

02: 45Hz, 03: 50Hz, 04: 55Hz, ...

09: maximum speed (80Hz)

3Slowdown speed 01...903 01: minimum speed (21Hz);

02: 22Hz, 03: 23Hz, 04: 24Hz, ...

09: maximum speed (29Hz)

6Maximum trapping current (each value

equivalent to 0.5A)

The digit D3 can be used to adjust

current to normal speed

The digit D4 can be used to adjust

current to slow speed

0...90...900 00: disabled;

01: disabled at normal speed and 0.5A at

slow speed;

10: 0.5A at normal speed and disabled at

slow speed; ...;

65: 3A at normal speed and 2.5A at slow

speed;...;

99: 4.5A at normal and slow speed

7Closing photocell used during standby

(in automatic mode only)

00 No effect

01 Immediate closing after crossing

02x Restarts standby time

8Effect of pushbuttons (ST1, ST2) during

stand-by time (in automatic mode only)

00 No effect

01 Cause immediate close

02x Restart stand-by time

9Opening mode 01 Collective opening

02x Step-by-step alternative shutdown

03 Automatic alternative shutdown (only in

automatic mode, F2 K00

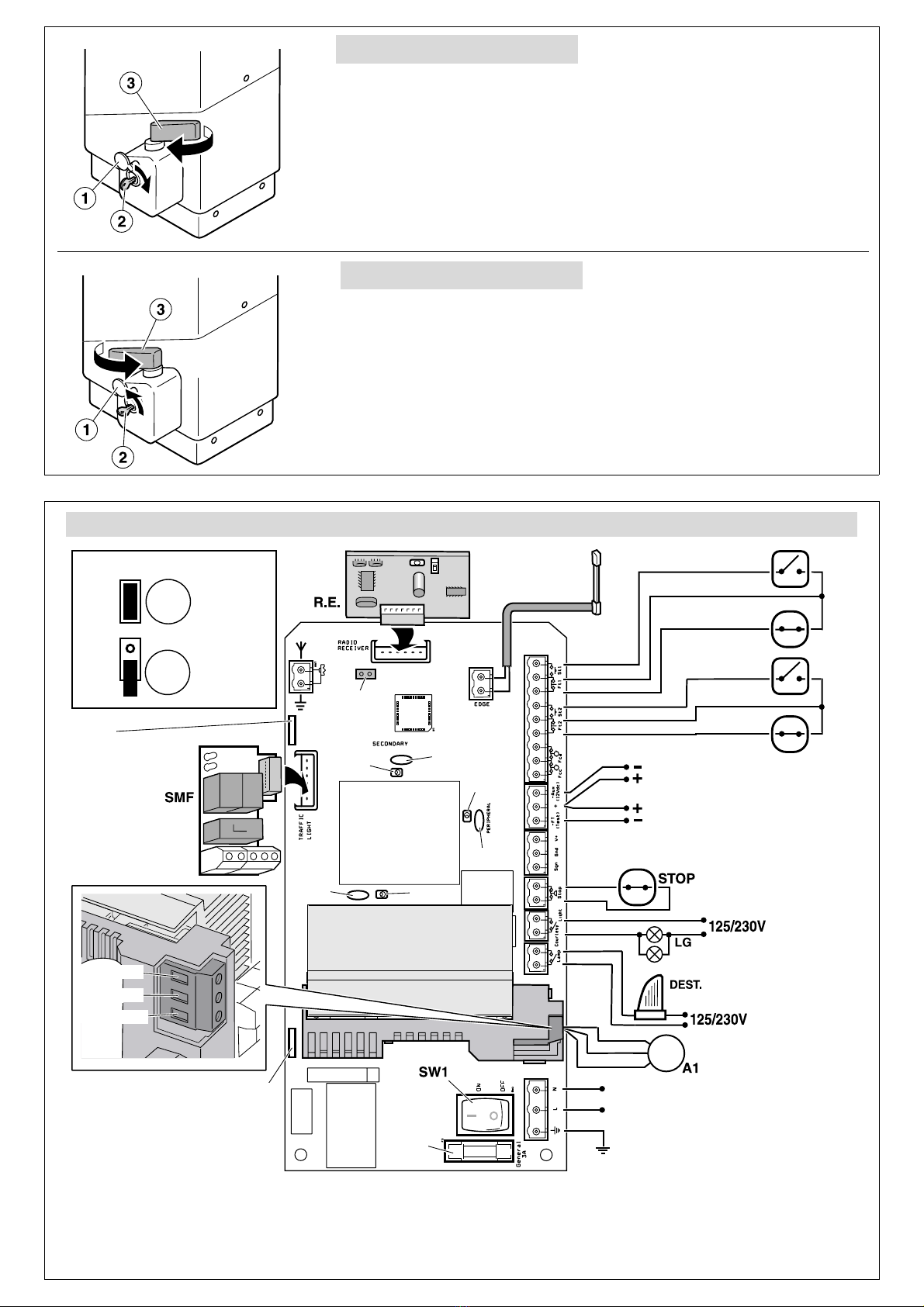

bUsing the EPS1 card connector

For parameters Ab02 and Ab03, use

the EPS1 card and bridge the network

input cable connectors instead of

disconnecting them from the network.

00x use for standard traffic light

01 use for brakes

02 NC contact with gate open (L1-COM) and

gate closed (L2-COM)

03 impulse 1 second Open (L1-COM) when

starting opening and Close (L2-COM) when

starting closing. Allows another board to be

activated

ESpecial functions 00x no special function

02 industrial

(1.5s delay in shutdown and reversing)

ç0Programming lock key

Be sure to remember any key used, for

future access to the programming

X X 0000 The preset option is 0000 (no key). If any

figure is changed, this is considered a key.

Select the required key (starting with D1)

using UP and DOWN. Press ESC to cancel or

ENTER to confirm and move to D2, and so

on.

1Operations carried out (total counter) XX Indicates the hundreds of cycles completed

(for example, 68 indicates 6,800 cycles

completed)

2Operations carried out (partial counter,

restarts with ST1 and ST2)

XX Indicates the hundreds of cycles completed

(for example, 68 indicates 6,800 cycles

completed)

3Restore to default values, operation,

radio and configuration

rS With the display showing ç3rS (with 3

flashing), press ENTER and b0rr will flash.

Hold down ENTER until D1 shows b,

restoring all programming menu values to

default.