Signet 9900 Transmitter

3-9900.091 Rev. 7 07/18 English

*3-9900.091*

Start-Up Guide

Look for the Quick Start icon to

quickly set up your new 9900.

The 9900 is compatible with all

GF Signet products listed in the

column to the right.

• pH and ORP electrodes require the

Signet 2750/2751 DryLoc®Sensor

Electronics (sold separately).

• Conductivity/Resistivity or Salinity

measurement requires either

the optional Direct Conductivity/

Resistivity Module (part number

3-9900.394) or the Signet 2850

Conductivity/Resistivity Sensor

Electronics (sold separately).

NOTE: If using the 2850, use ONLY

the one-channel Digital (S3L) models

3-2850-51/-61, or the 2-channel

model 3-2850-63 with only one

channel connected. Do not use

with both channels connected. The

4 to 20 mA models 3-2850-52 and

3-2850-62 are not compatible with

the 9900.

• Turbidity measurement using

Signet 4150 or Dissolved

• Oxygen measurement using

Signet 2610-31 requires Signet

8058 i-Go®Signal Converter

(sold separately).

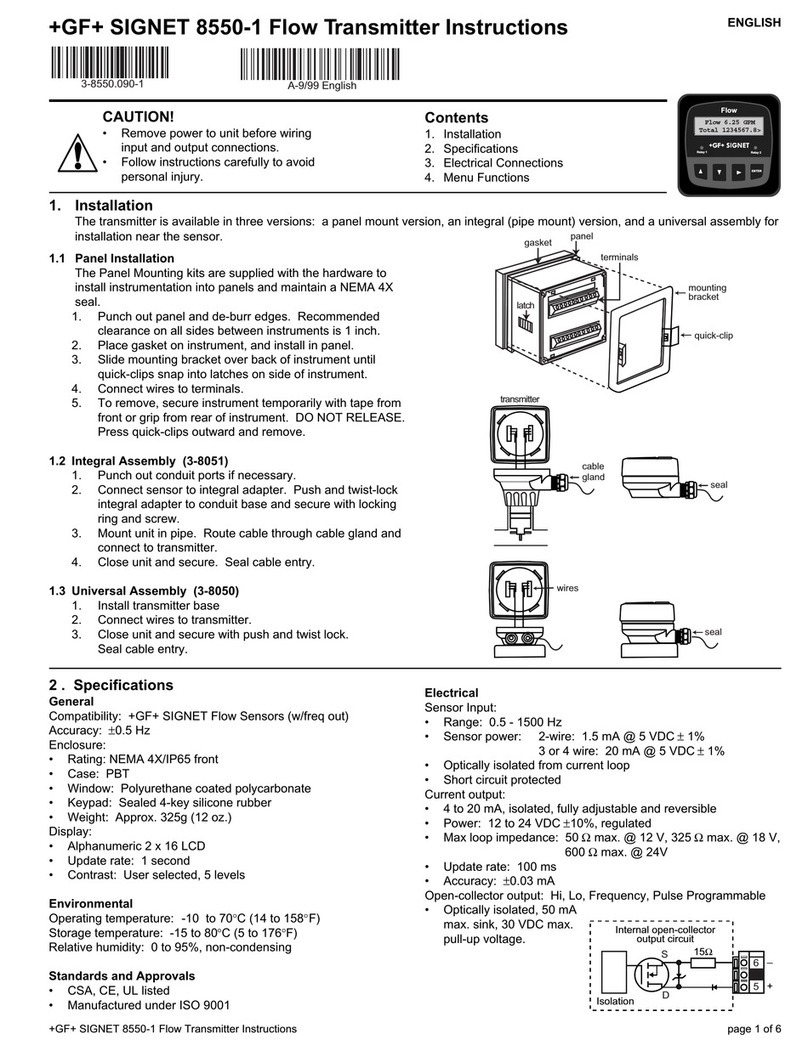

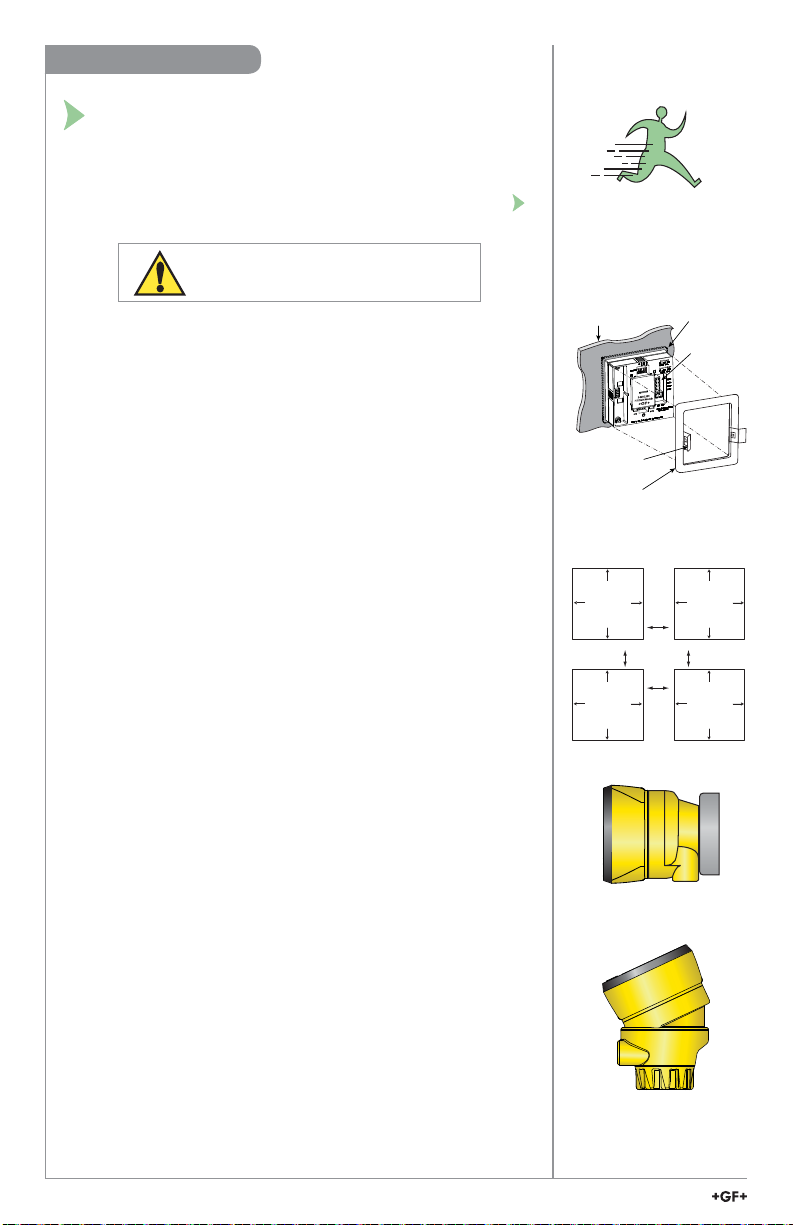

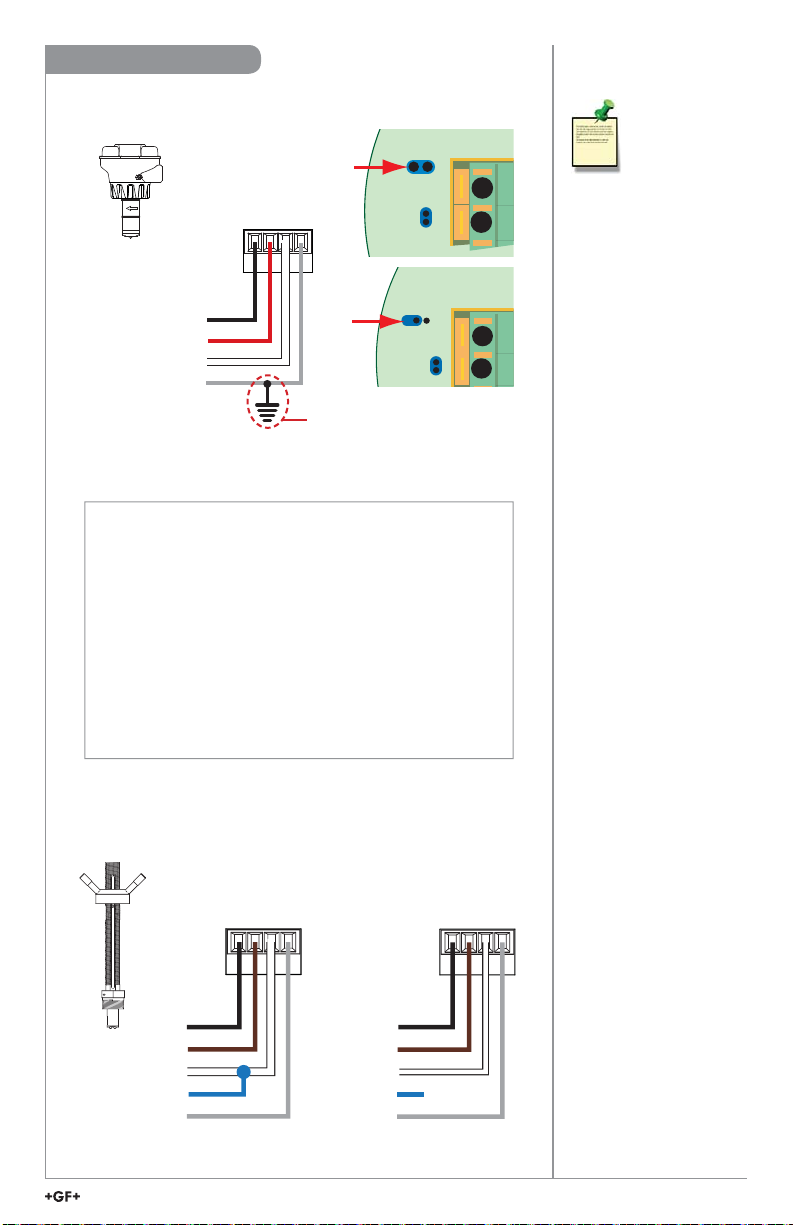

Field Mount

Panel Mount

English, Deutsch, 中文

The 9900 Transmitter, a member of Signet's line of SmartPro®

instruments, provides a single-channel interface for all Flow,

pH/ORP, Conductivity/Resistivity, Salinity, Pressure, Temperature,

Level, Dissolved Oxygen, Turbidity, Batch and other applications.

The 9900 is available in either Panel or Field Mount, runs on

10.8 to 35.2 VDC power (24 VDC nominal), and can power

certain sensors on loop power (see NOTE on page 7).

The 9900 Transmitter, also allows third-party 4 to 20 mA signals

to be used as an input (optional Signet 8058 i-Go®Signal

Converter required, sold separately).

• English

• Deutsch

• Français

• Español

• Italiano

• 中文

Compatibility

Flow

515*/8510*, 525*, 2000,

2100, 2507, 2536*/8512*,

2537, 2540*, 2551, 2552

pH/ORP

2724-2726 with 2750*/2751

2734-2736 with 2750*/2751

2756-WTx–2757-WTx with

3719 and 2750*/2751

2764-2767 with 2750*/2751

2774-2777 with 2750*/2751

Conductivity/Resistivity,

Salinity

2819-2823 with 2850 or

Cond/Res Module

2839-2842 with 2850 or

Cond/Res Module

Level, Temperature,

Pressure

2250*, 2350*, 2450*

Turbidity

4150 requires 8058

Dissolved Oxygen

2610-41, 2610-51 direct

to 9900

*Can be run on Loop Power

(see NOTE on page 7)

Description