10 9950 Transmitter

Operating Instructions

Thank you for purchasing the Signet line of Georg

Fischer measurement products.

If you would like to register your product(s), you can now

register online in one of the following ways:

• Visit our website www.gfsignet.com.

Under Service and Support click Product

Registration Form

• If this is a pdf manual (digital copy), click here

Refer to your local Georg Fischer Sales office for the

most current warranty statement.

All warranty and non-warranty repairs being returned

must include a fully completed Service Form and

goods must be returned to your local GF Sales office or

distributor.

Product returned without a Service Form may not be

warranty replaced or repaired.

Signet products with limited shelf-life (e.g. pH, ORP,

chlorine electrodes, calibration solutions; e.g. pH buffers,

turbidity standards or other solutions) are warranted out

of box but not warranted against any damage, due to

process or application failures (e.g. high temperature,

chemical poisoning, dry-out) or mishandling (e.g. broken

glass, damaged membrane, freezing and/or extreme

temperatures).

Warranty Information Table of Contents

Product Registration

General Information .........................................................2

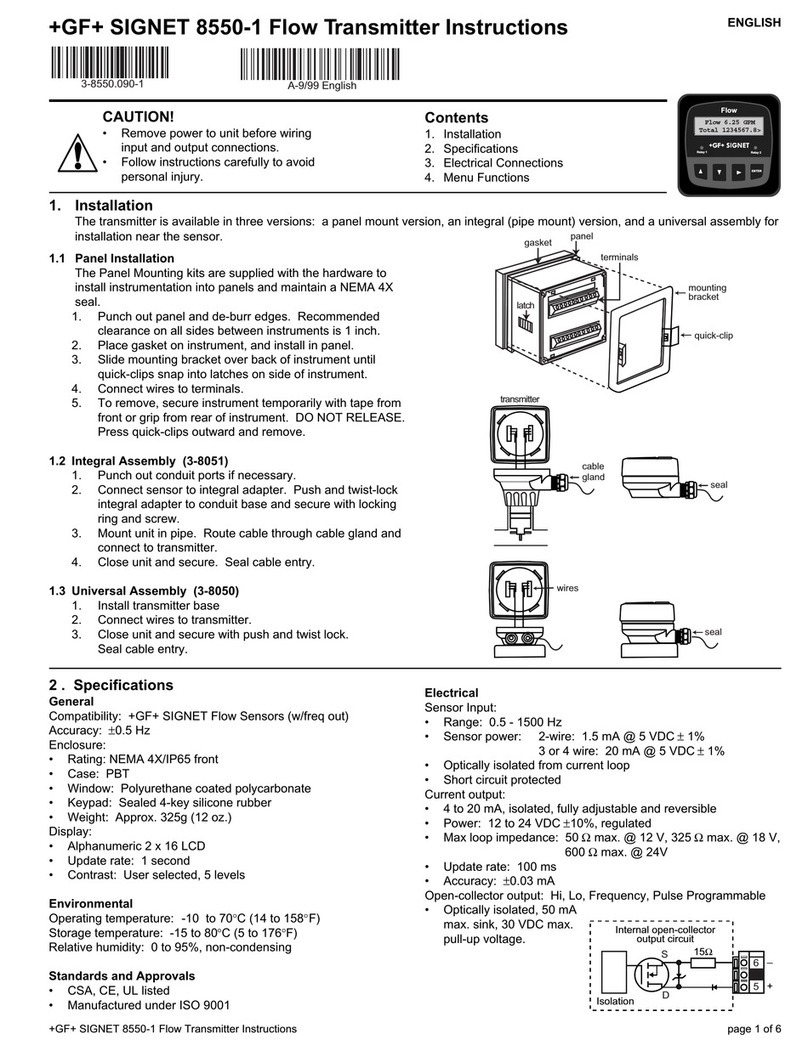

Safety Information/Installation..........................................2

Terminal Identification ......................................................3

Wiring ...............................................................................4

Sensor Wiring.............................................................4

Sensor Wiring.............................................................5

Power Wiring..............................................................6

Relay Module Wiring..................................................7

Operation .........................................................................8

Password ...................................................................9

Keypad Operation ......................................................9

Signal Type: 4 to 20 mA...........................................10

Warranty Information................................................10

Product Registration ................................................10

Table of Contents .....................................................10

Dimensions ..............................................................11

Module Installation ................................................... 11

Plug-In Modules .............................................................12

Relay Modules ...............................................................12

Signal Type: Frequency ................................................13

Signal Type: Digital (S3L) ..............................................13

Signal Type: 4 to 20 mA................................................14

Relay Functions .............................................................14

Relay Modes ............................................................15

Derived Functions ....................................................19

Menu System .................................................................20

Common Menu ........................................................21

Loop Menus .............................................................21

Relay Menu ..............................................................22

Option Menu.............................................................24

View Mode ...............................................................26

Sensor-Specific Menus..................................................28

Flow..........................................................................28

pH.............................................................................30

ORP..........................................................................32

Conductivity/Resistivity ............................................34

Pressure...................................................................36

Level/Volume............................................................38

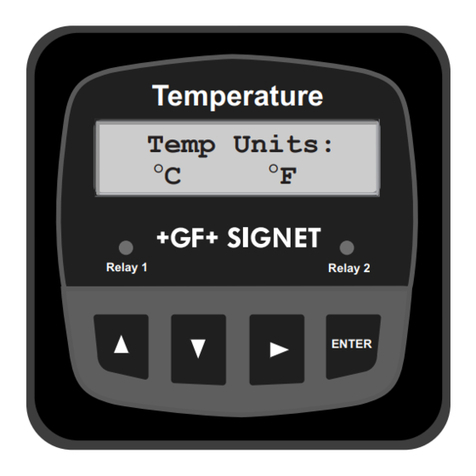

Temperature .............................................................41

4 to 20 mA................................................................42

Salinity......................................................................44

Dissolved Oxygen ....................................................46

Field Software Update ...................................................48

Updating the 9950..........................................................48

Troubleshooting .............................................................49

Appendix ........................................................................51

Averaging .................................................................51

LOG Current Loop Output .......................................51

Custom Measurements............................................52

Calibration Procedures - pH.....................................56

Calibration Procedure - ORP ...................................58

Calibration Procedure - Conductivity/Resistivity......60

Calibration Procedure - Flow ...................................61

Calibration Error Messages .....................................62

USP Limits................................................................63

Maintenance.............................................................63

Map of 9950 Relay and Loop Sources ....................64

Specifications .................................................................65

Ordering Information ......................................................68