1

Content

1. Safety and responsibility ..............................................................................................................................3

1.1 Intended use ...............................................................................................................................................3

1.2 Safety regulations for the Ex approved units............................................................................................3

2. Transport and storage..................................................................................................................................3

3. Design and function......................................................................................................................................3

3.1 Design .........................................................................................................................................................3

3.2 Function ......................................................................................................................................................4

3.3 Basic concepts and elements of the ultrasonic measurement...............................................................4

3.4 Identification...............................................................................................................................................5

4. Technical Data ..............................................................................................................................................6

4.1 Dimensions.................................................................................................................................................7

4.2 Scope of delivery ........................................................................................................................................7

4.3 Maintenance and repair.............................................................................................................................7

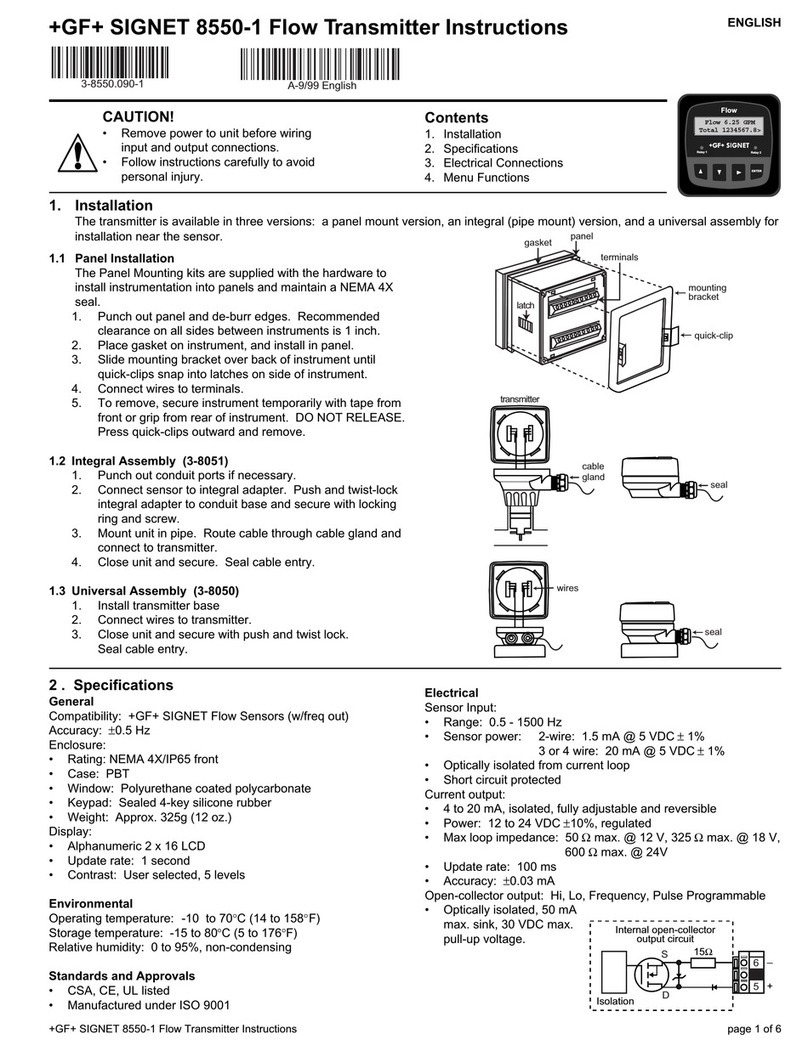

5. Installation ....................................................................................................................................................8

5.1 Liquid Level Measurement ........................................................................................................................8

5.2 Installation and electrical connection.....................................................................................................10

5.2.1 Installation of the (BSP or NPT) threaded models .........................................................................10

5.2.2 Details electrical connection.............................................................................................................11

5.3 Loop current checking.............................................................................................................................12

6. Programming in general............................................................................................................................13

6.1 Programming without display module....................................................................................................13

6.1.1 Procedure of programming ..............................................................................................................14

6.1.2 Teach-in: Minimum level, (empty tank) assignment to 4 mA .........................................................14

6.1.3 Teach-in: Maximum level (full tank) assignment to 20 mA.............................................................14

6.1.4 “Error state” indication by the analogue signal...............................................................................14

6.1.5 Damping time setting ........................................................................................................................15

6.1.6 RESET: Returning to the default.......................................................................................................15

6.1.7 Indication of mistakes (by LEDs) made during programming ........................................................15

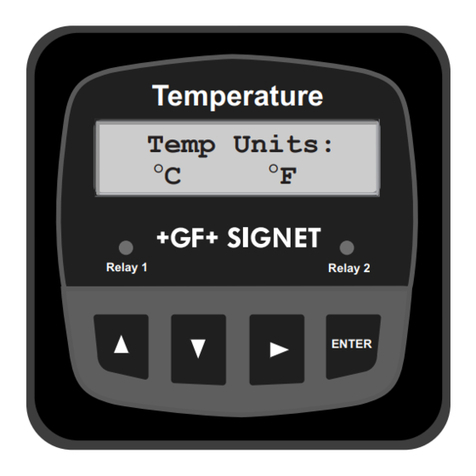

6.2 Programming with the Display Module ..................................................................................................16

6.2.1 Display Module...................................................................................................................................16

6.2.2 Steps of the Display Module..............................................................................................................17

6.2.3 Indications of the DISPLAY MODULE and LED Status.....................................................................18

6.2.4 QUICKSET...........................................................................................................................................19

6.2.5 Full parameter access ......................................................................................................................20