4

Contents

Original instruction manual ............................................................................................................ 3

Contents........................................................................................................................................... 4

1Intended use .......................................................................................................................... 6

2About this document ............................................................................................................. 6

2.1 Warnings ................................................................................................................................ 6

3Safety and responsibility ....................................................................................................... 6

4Transport and storage........................................................................................................... 7

5Design and function............................................................................................................... 7

5.1 Function ................................................................................................................................. 7

5.2 Principle of operation............................................................................................................ 7

6Technical data........................................................................................................................ 9

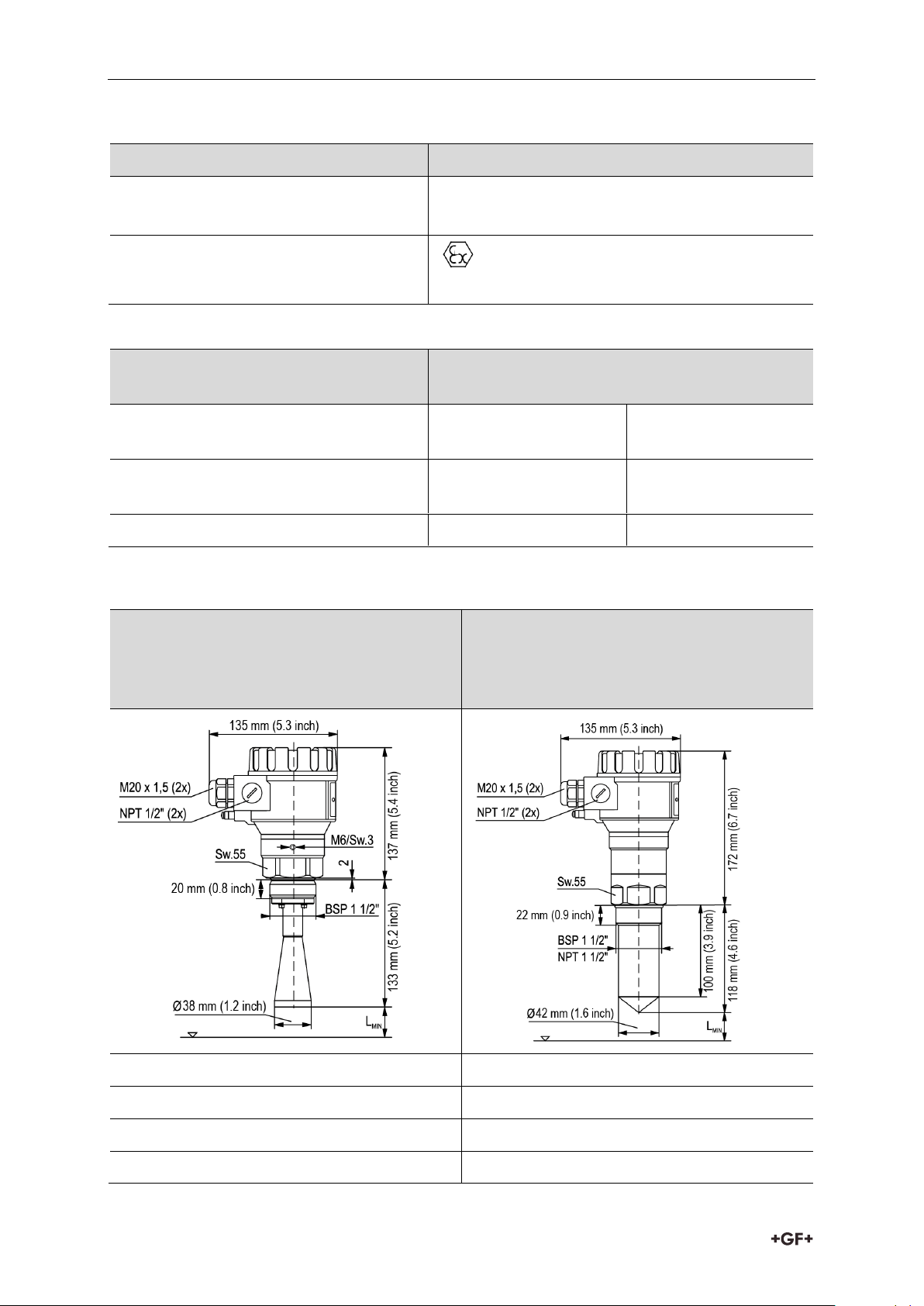

6.1 Dimensions ...........................................................................................................................10

6.2 Determining the maximum measuring range ....................................................................11

7Conditions of safe operation ................................................................................................12

8Installation ............................................................................................................................12

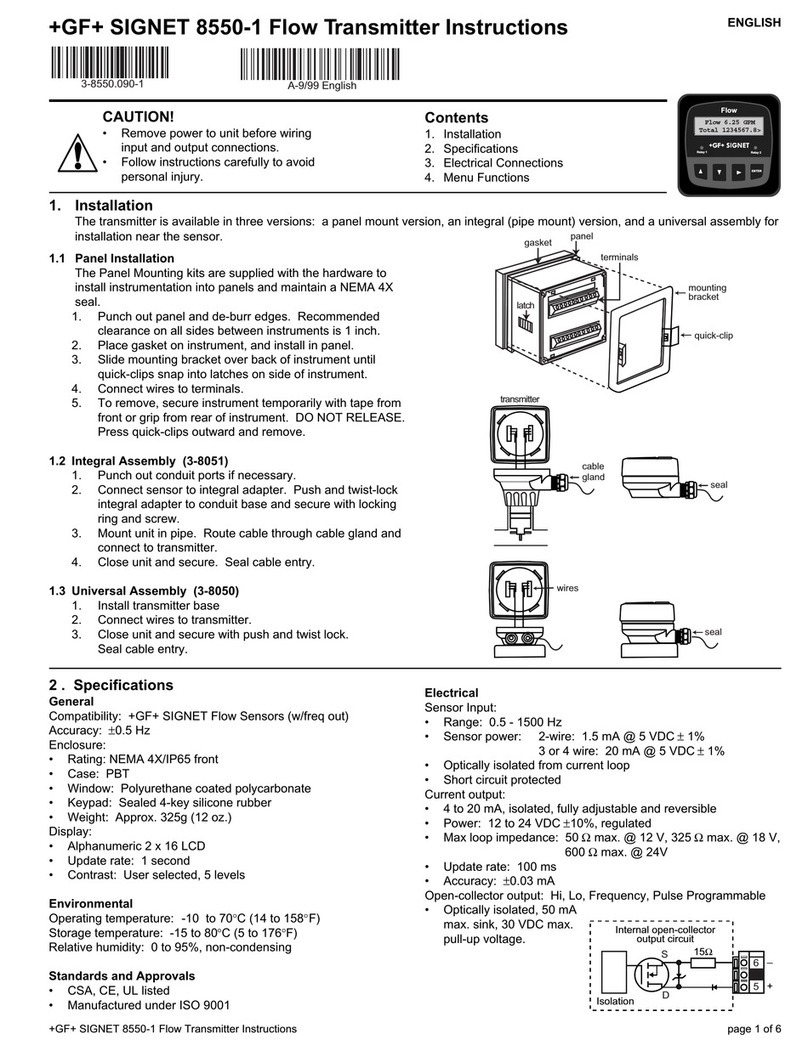

8.1 Mounting ...............................................................................................................................12

8.2 Wiring ....................................................................................................................................14

8.2.1 Wiring of the devices ............................................................................................................15

8.2.2 Determine the appropriate power supply voltage ..............................................................16

8.3 Loop current checking with hand instrument ....................................................................17

9Programming 2290 Level Transmitter ...............................................................................18

9.1 The display unit.....................................................................................................................18

9.1.1 Information Screens.............................................................................................................20

9.1.2 Echo Map...............................................................................................................................21

9.2 Programming with the display module...............................................................................21

9.2.1 Components of the programming interface .......................................................................21

9.2.2 Menu structure .....................................................................................................................23

9.3 Programmable features description...................................................................................23

9.3.1 Basic measurement setting.................................................................................................23

9.3.2 Output setup..........................................................................................................................25

9.3.3 Digital output ........................................................................................................................26

9.3.4 Optimization..........................................................................................................................26

9.3.5 Calculations ..........................................................................................................................29

9.3.6 Service ..................................................................................................................................32

10 Repair and Maintenance ......................................................................................................34