4

Contents

Original instruction manual ............................................................................................................ 3

Contents........................................................................................................................................... 4

1Intended use .......................................................................................................................... 5

2About this document ............................................................................................................. 5

2.1 Warnings ................................................................................................................................ 5

3Safety and responsibility ....................................................................................................... 5

4Transport and storage........................................................................................................... 6

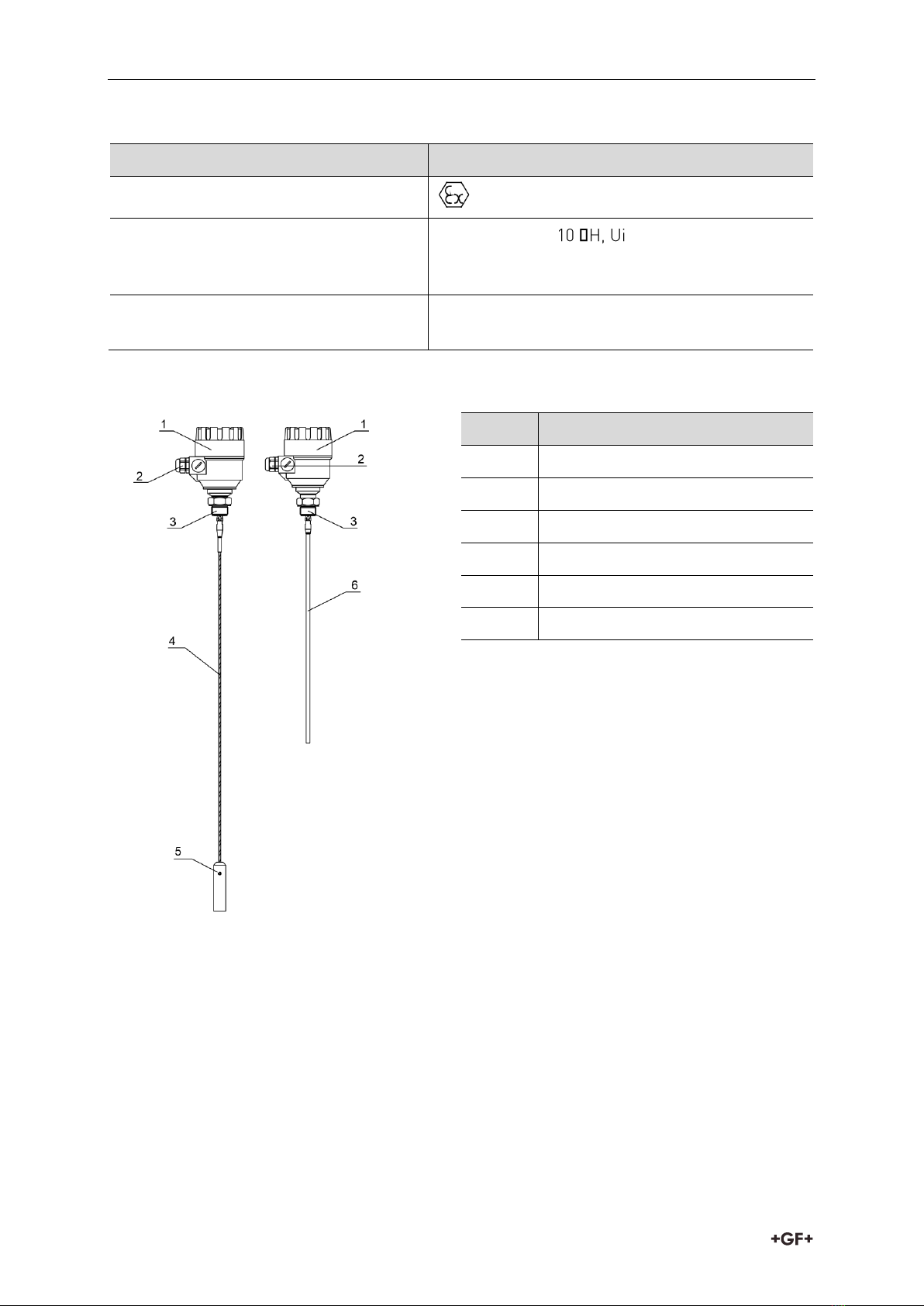

5Design and function............................................................................................................... 6

5.1 Function ................................................................................................................................. 6

5.2 Principle of operation............................................................................................................ 6

6Technical data........................................................................................................................ 7

6.1 Dimensions ............................................................................................................................ 8

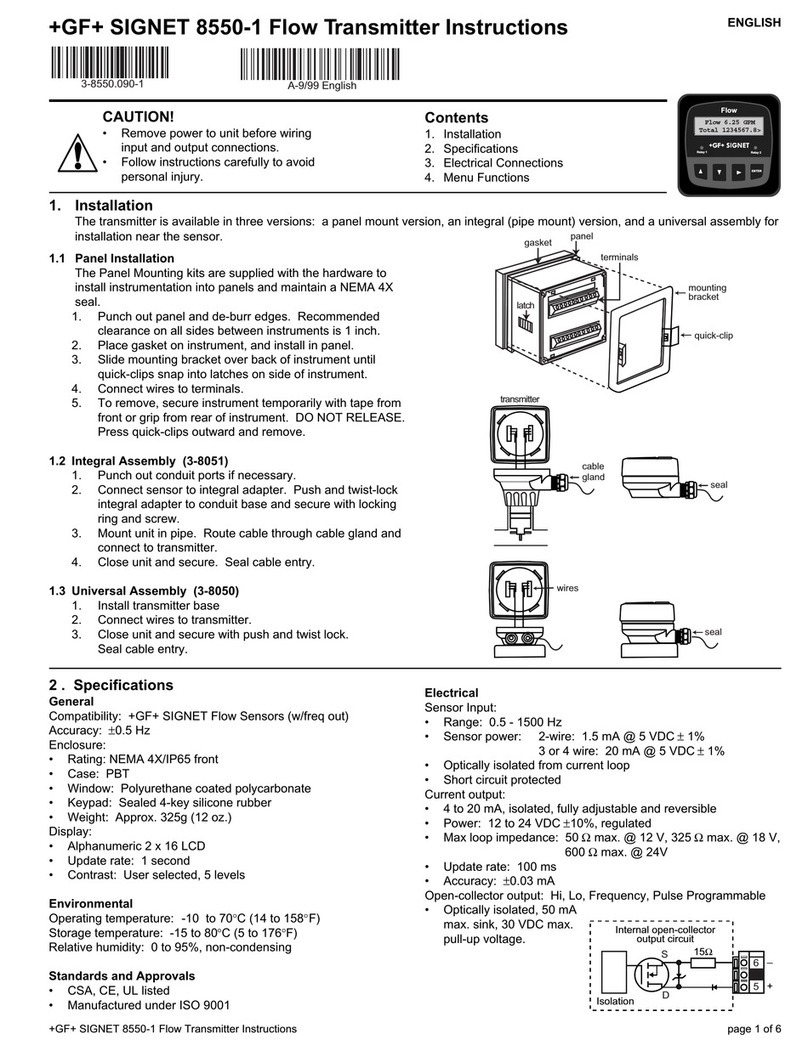

7Installation ............................................................................................................................. 9

7.1 Handling and Storage............................................................................................................ 9

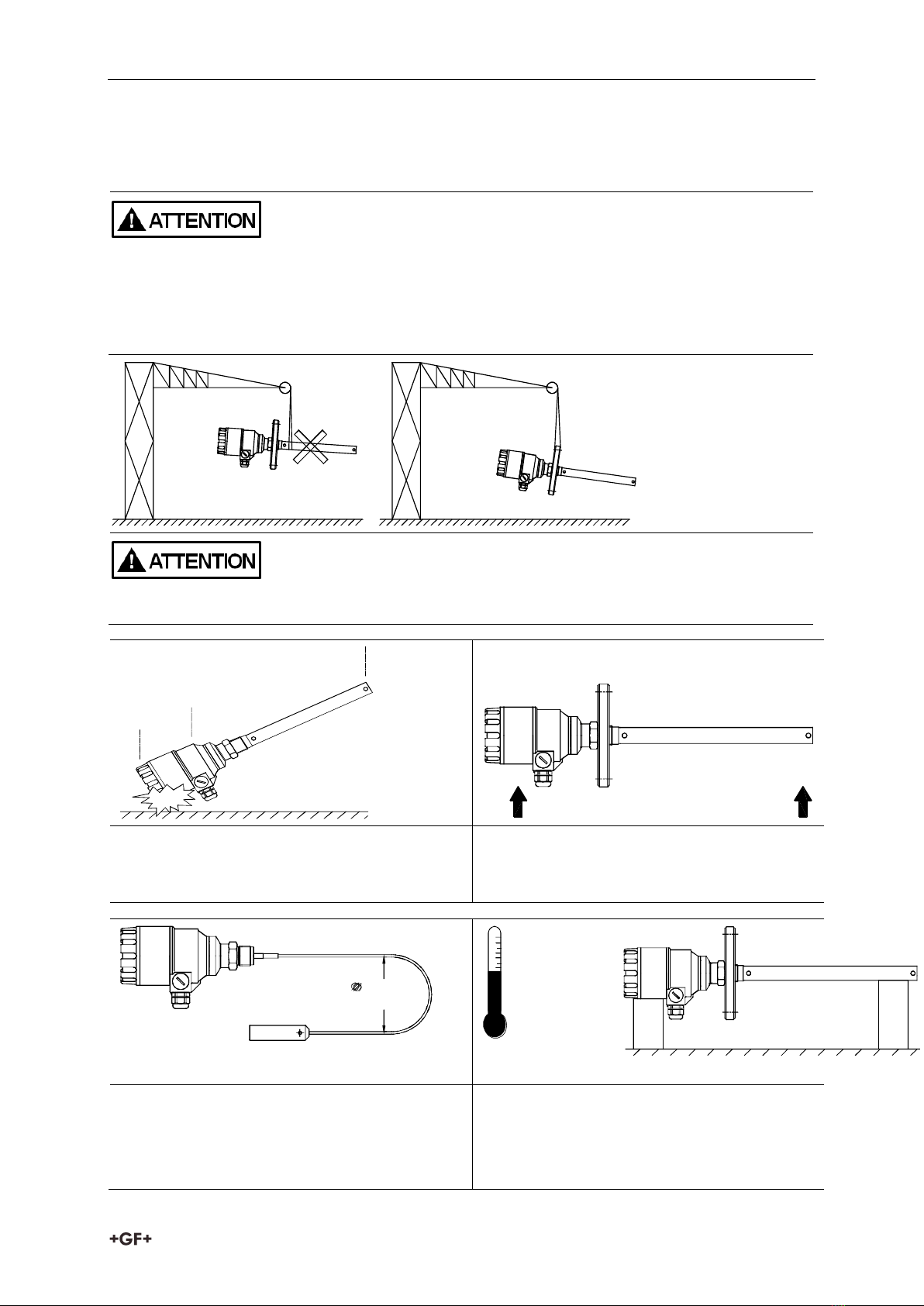

7.2 Mounting on the tank ...........................................................................................................10

7.2.1 Installation instructions: General notes..............................................................................10

7.2.2 Specific installation instructions: Gauge –solid applications ...........................................13

7.3 Wiring ....................................................................................................................................14

7.4 Power on and start-up .........................................................................................................17

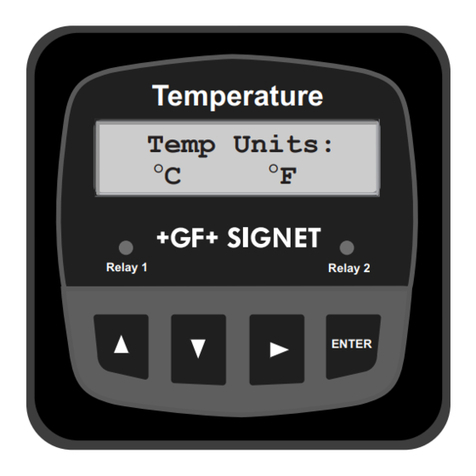

8Programming type 2291.......................................................................................................18

8.1 The display unit.....................................................................................................................18

8.1.1 Behavior in manuals programming mode ..........................................................................18

8.1.2 Manual programming...........................................................................................................19

8.2 Characteristics .....................................................................................................................20

8.2.1 Gauge operating logic when the reflection is lost ..............................................................21

8.2.2 Gain and voltage amplitude..................................................................................................22

8.2.3 Typical signal trends ............................................................................................................24

8.2.4 Automatic adjustment..........................................................................................................25

8.2.5 Level measurement when more than one phase or layer in the tank ..............................25

9Troubleshooting....................................................................................................................27

10 Repair and Maintenance ......................................................................................................30

11 Accessories...........................................................................................................................30

12 Set-up parameters ...............................................................................................................30

13 Disposal.................................................................................................................................30