1Signet 8250-2 Level Transmitter

CAUTION!

• Remove power to unit before wiring

input and output connections.

• Follow instructions carefully to avoid

personal injury.

Signet 8250-2 Level Transmitter English

Contents

1. Description

2. Specifications

3. Panel installation

4. Electrical Connections

5. System configuration

Signet Level

Transmitter

Level

+10.00 ft

Relay 1 Relay 2

ENTER

1. Description

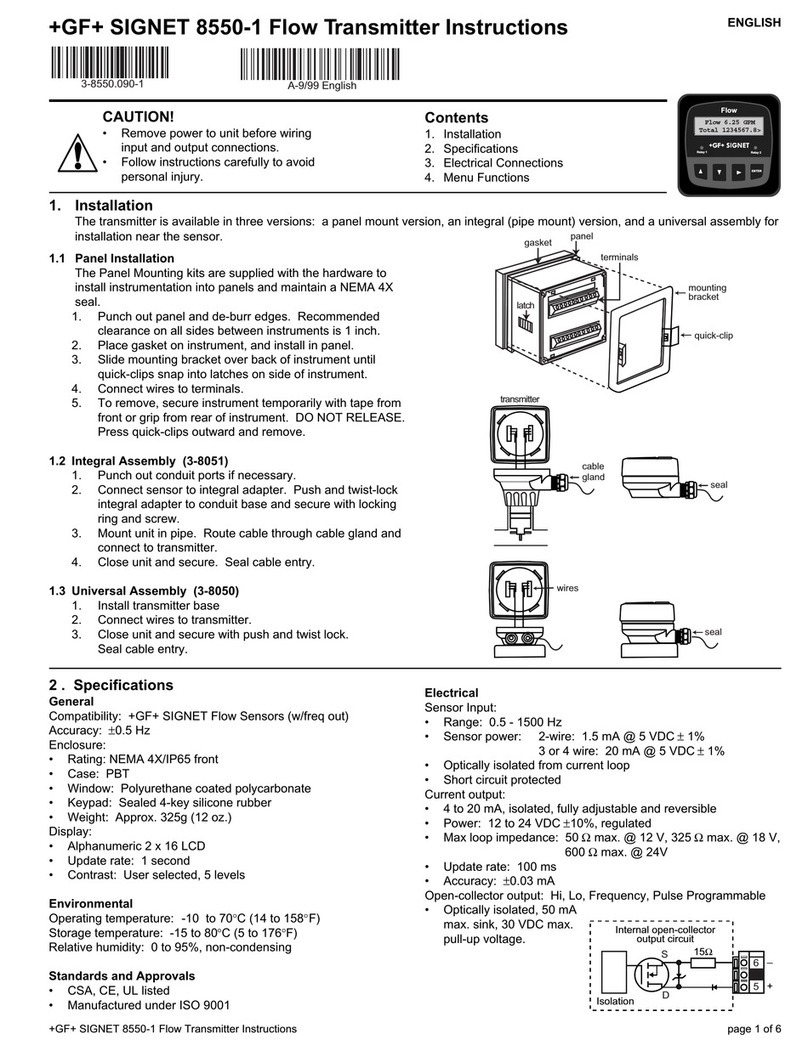

ProcessPro transmitters are available in two styles: panel mount and field mount. The panel mount is supplied with the necessary

hardware to install the transmitter. This manual includes complete panel mounting instructions.

Field mounting requires one of two separate mounting kits. The 3-8052 integral kit joins sensor and instrument together into a single

package. The 3-8050 Universal kit enables the transmitter to be installed virtually anywhere.

Detailed instructions for integral mounting or other field installation options are included with the 3-8052 Integral kit or the 3-8050

Universal kit.

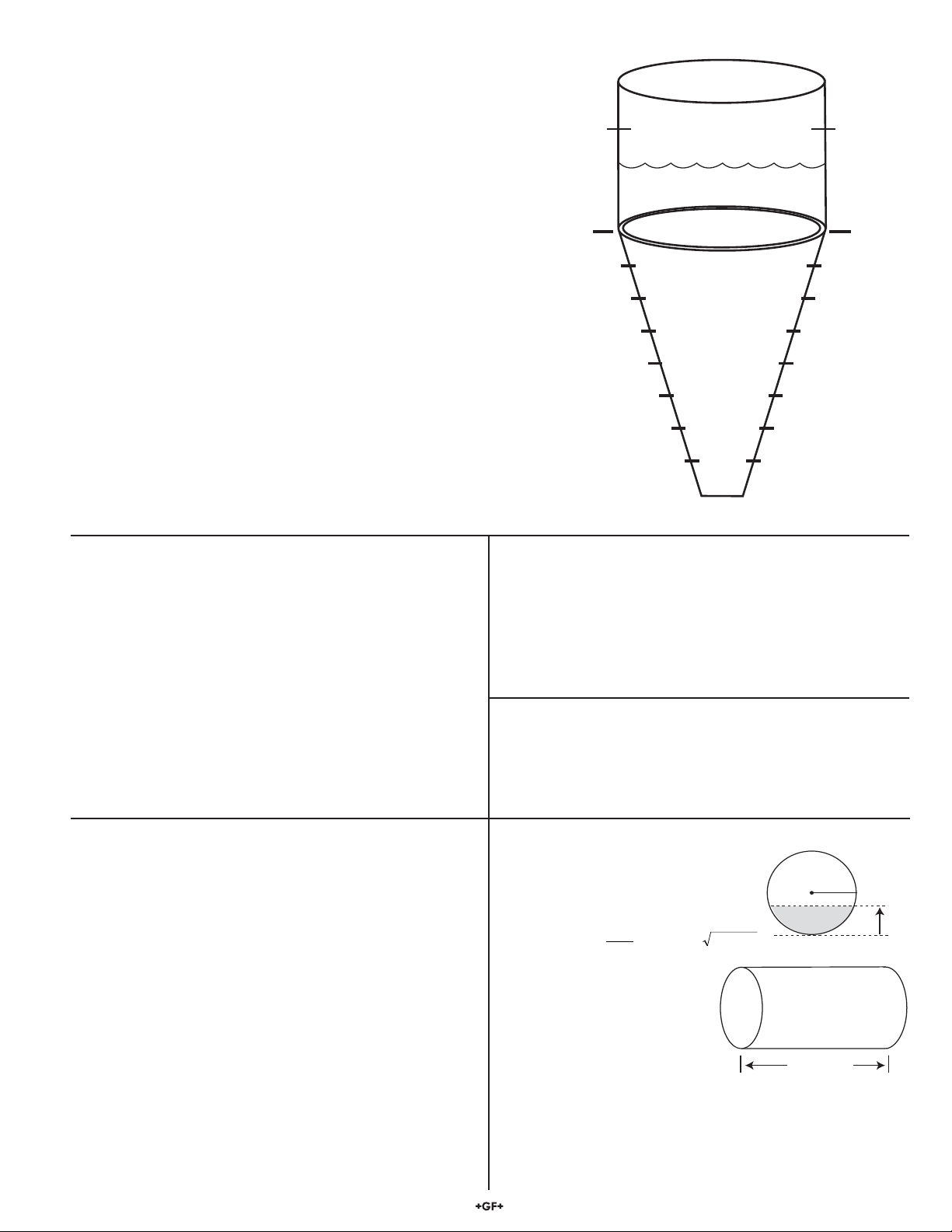

General

Compatible Sensors: Signet 2450 Pressure Sensor (S3L)

Signet 2250 Level Sensor (S3L)

Other 3rd party sensors with 4 to 20 mA

output (via Model 8058)

Materials:

• Case: PBT

• Panel case gasket: Neoprene

• Window: Polyurethane-coated polycarbonate

• Keypad: Sealed silicone rubber, 4-button

Weight: Approx. 325 g (12 oz.)

Display:

• Alphanumeric 2 x 16 LCD

• Display update rate: 1 second

• Contrast: User selected, 5 levels

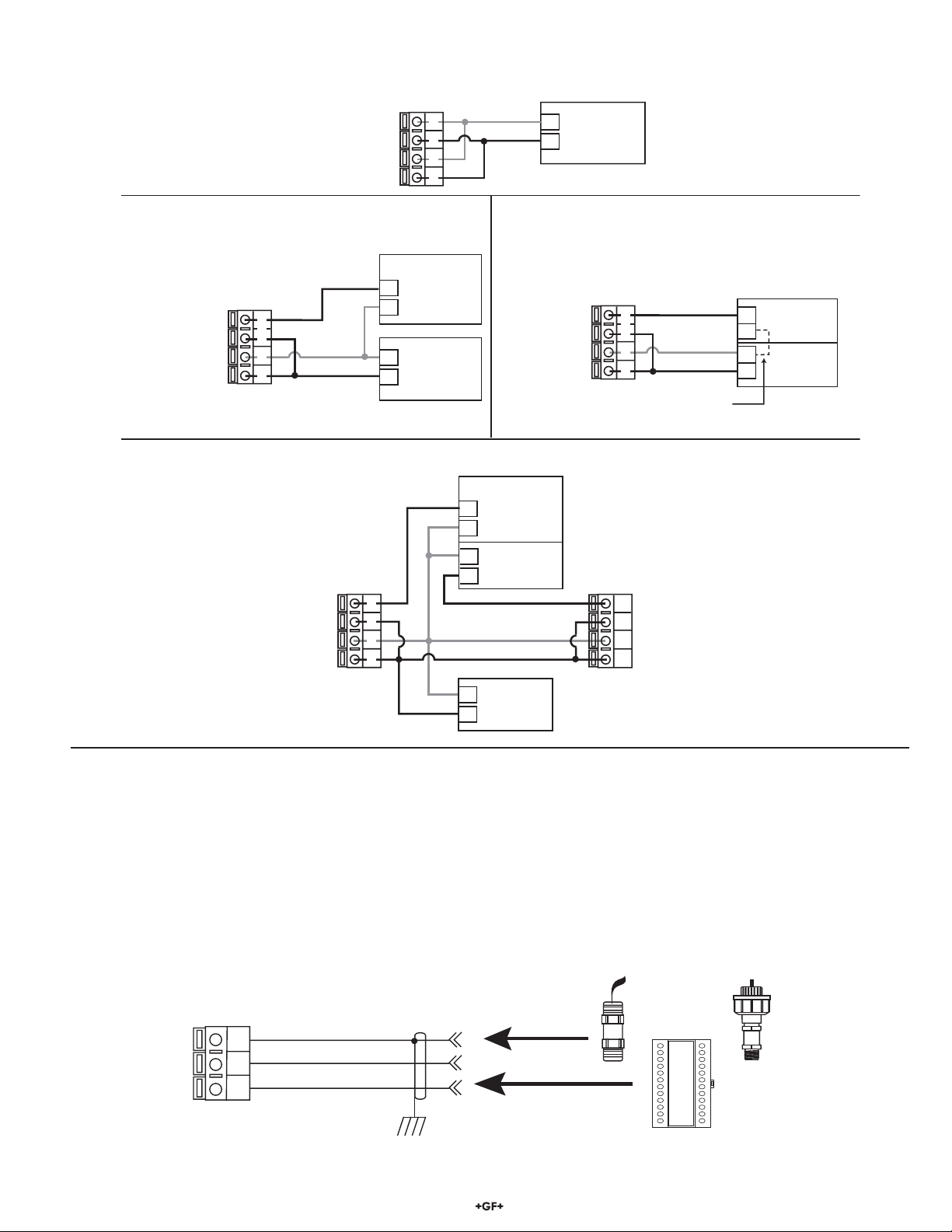

Electrical

Power supply: 12-24 VDC ±10% regulated,

250 mA max current

Sensor power: 5 VDC ±1% @ 25 ºC, regulated

2-wire system: 1.5 mA maximum current

4-wire system: 20 mA maximum current

Current output:

• 4 to 20 mA, isolated, fully adjustable and reversible

• Max loop impedance: 50 Ωmax. @ 12 V

325 Ωmax. @ 18 V

600 Ωmax. @ 24 V

• Update rate: 300 ms

• Output accuracy: ±0.03 mA

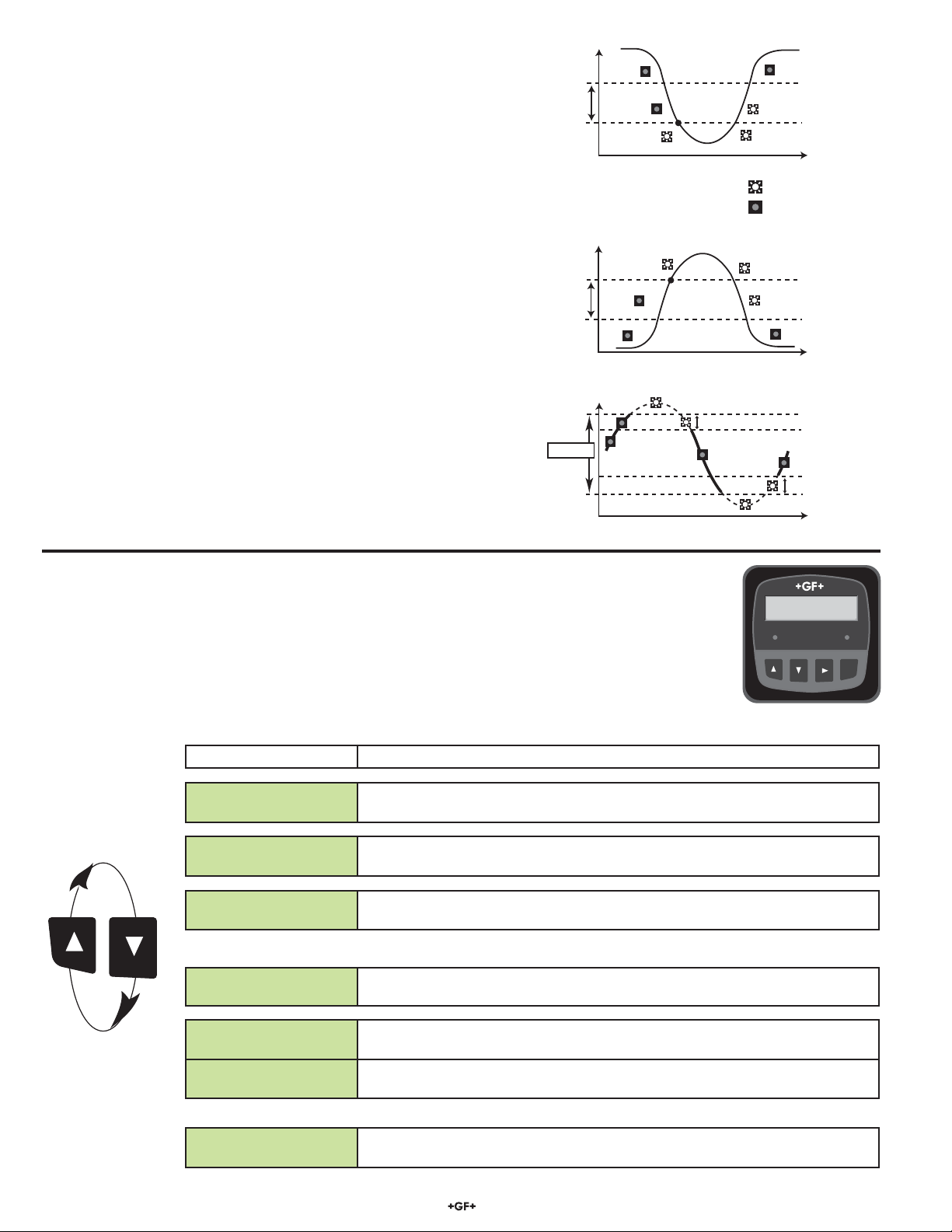

Relay outputs (2 sets mechanical SPDT contacts):

• Software supports 2 additional relays via optional external relay module

Note: When using the 8059-4 or -4AC, only relays 1 and 2 can be

utilized with the level instrument.

• Maximum voltage rating:

5 A @ 30 VDC, or 5 A @ 250 VAC, resistive load

• Programmable for High or Low setpoint or for Window range,

with adjustable hysteresis

• May be disabled if not used

• Time delay: Programmable from 0 s to 6400 s

Environmental:

• Operating temperature: -10 °C to 70 °C (14 °F to 158 °F)

• Storage temperature: -15 °C to 80 °C (5 °F to 176 °F)

• Relative humidity: 0 to 95%, non-condensing

• Maximum altitude: 2000 m (6562 ft)

• Enclosure: NEMA 4X/IP65 front

Standards and Approvals:

• CE, UL listed

• Immunity: EN50082-2

• Emissions: EN55011

• Safety: EN61010

• Manufactured under ISO 9001 for Quality, ISO 14001 for

Environmental Management and OHSAS 18001 for

Occupational Health and Safety.

China RoHS (Go to www.gfsignet.com for details)

Declaration of Conformity according to FCC Part 15

This device complies with Part 15 of the FCC rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and,

(2) This device must accept any interference received, including

interference that may cause undesired operation.

2. Specifications

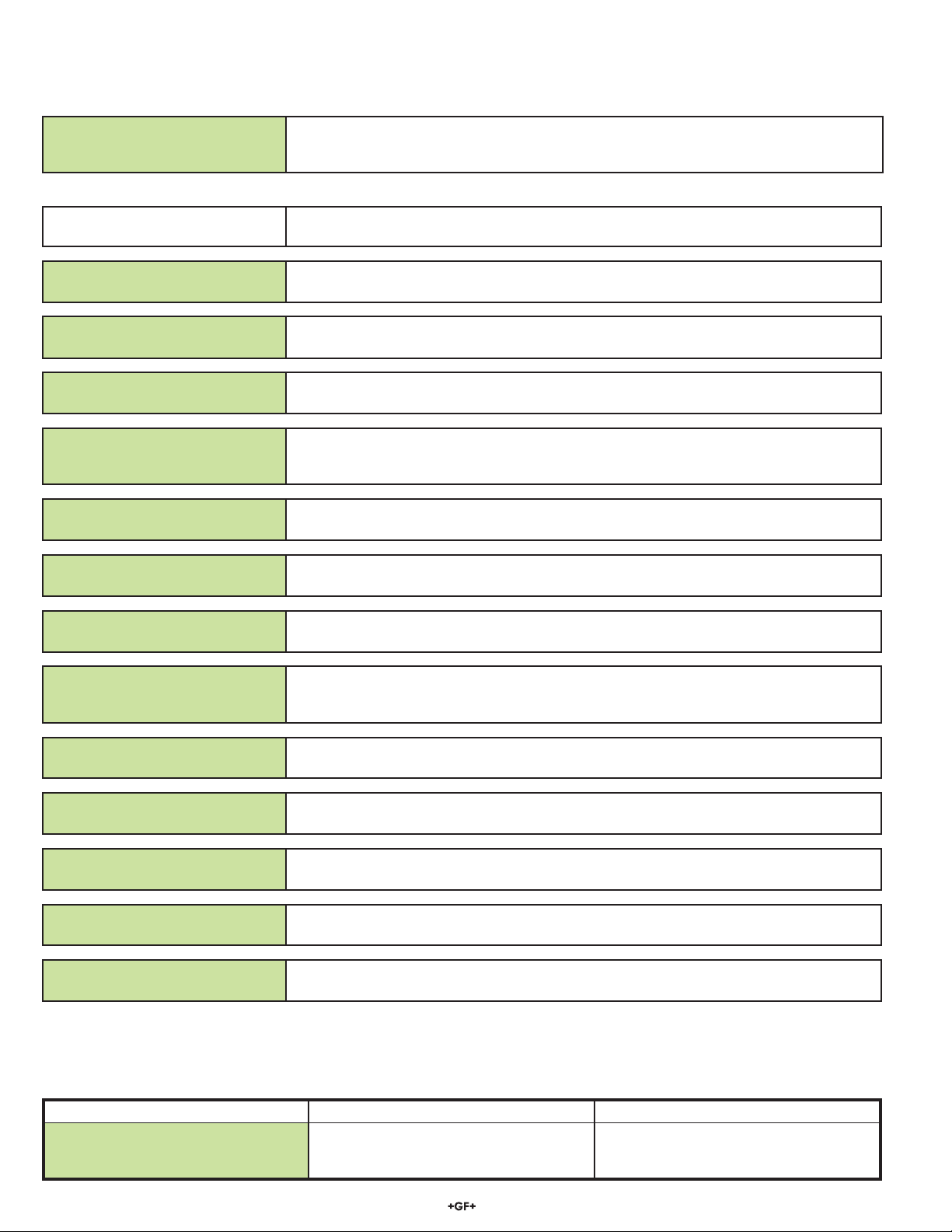

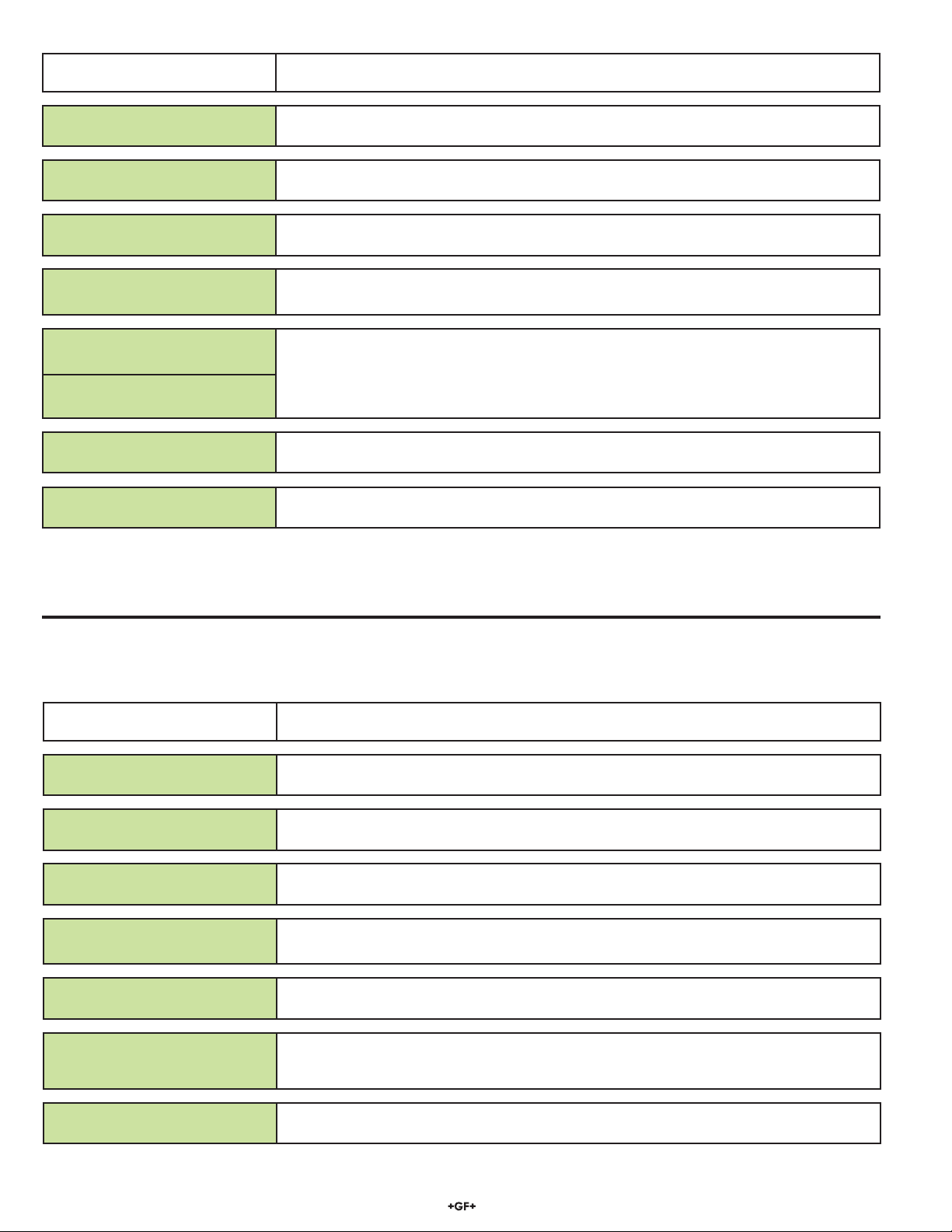

Dimensions

3-8250.090-2 Rev. H 01/13 English

3-8250.090-2

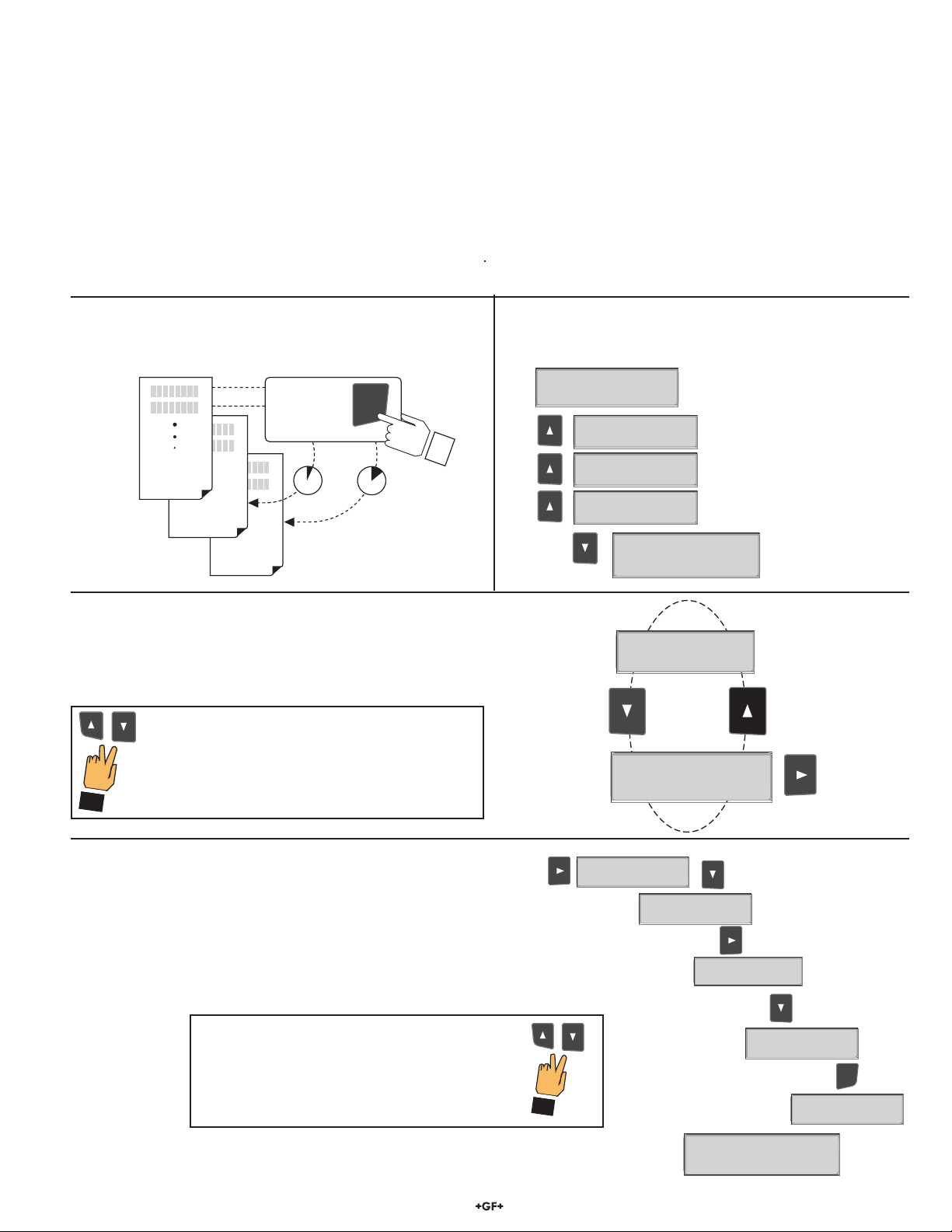

6. View menu

7. Editing procedure

8. Calibrate menu

9. Options menu

10. Troubleshooting

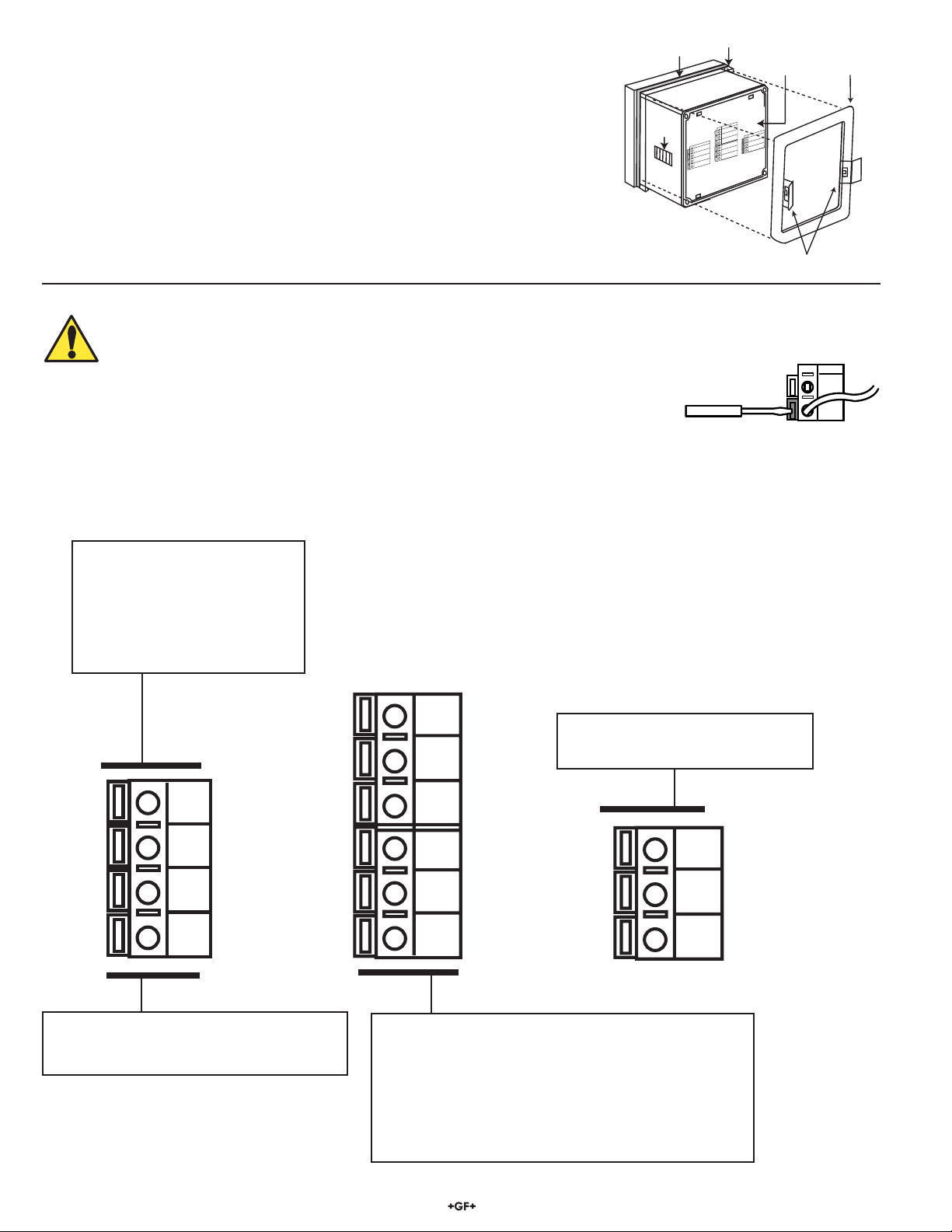

92 mm

(3.6 in.)

97 mm

(3.8 in.)

56 mm

(2.2 in.)

41 mm

(1.6 in.)

Optional

Rear

Cover

96 mm

(3.8 in.)

96 mm

(3.8 in.)

106 mm

(4.18 in.)

82 mm

(3.23 in.)

SIDE VIEW

Field Mount w/

8052 Integral kit

107 mm

(4.2 in.)

96 mm

(3.8 in.)

Panel Mount

SIDE VIEW

FRONT VIEW

Field Mount &

Panel Mount

SIDE VIEW

Field Mount w/

8050 Universal base