page 1 of 8

8350-3 Temperature Transmitter Instructions

CAUTION!

• Remove power to unit before wiring

input and output connections.

• Fo ow instructions carefu y to avoid

persona injury.

+GF+ SIGNET 8350-3 Temperature Transmitter Instructions ENG ISH

Contents

1. Insta ation

2. Specifications

3. E ectrica Connections

4. Menu Functions

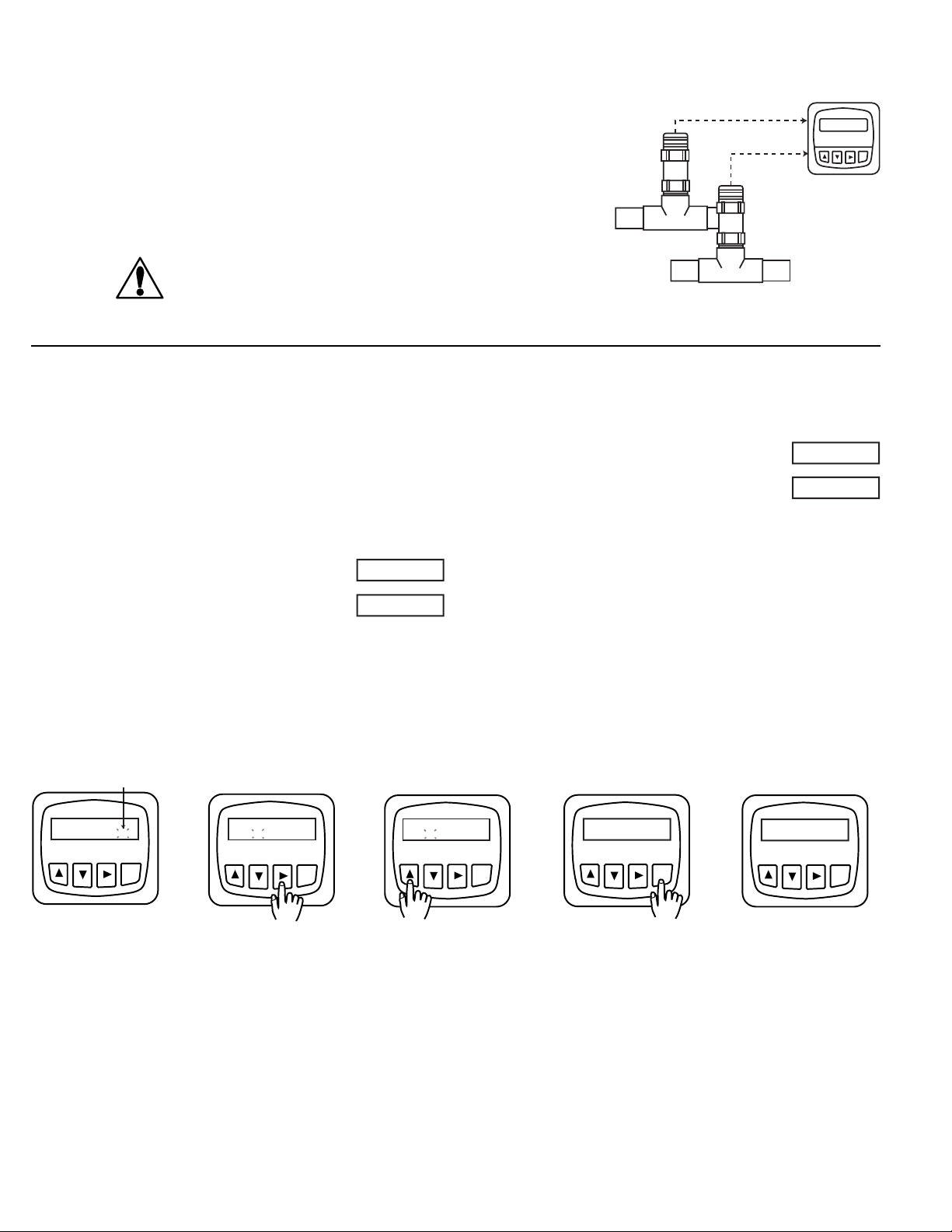

Temperature

Temp Units:

°C °F

Relay 1 Relay 2

ENTER

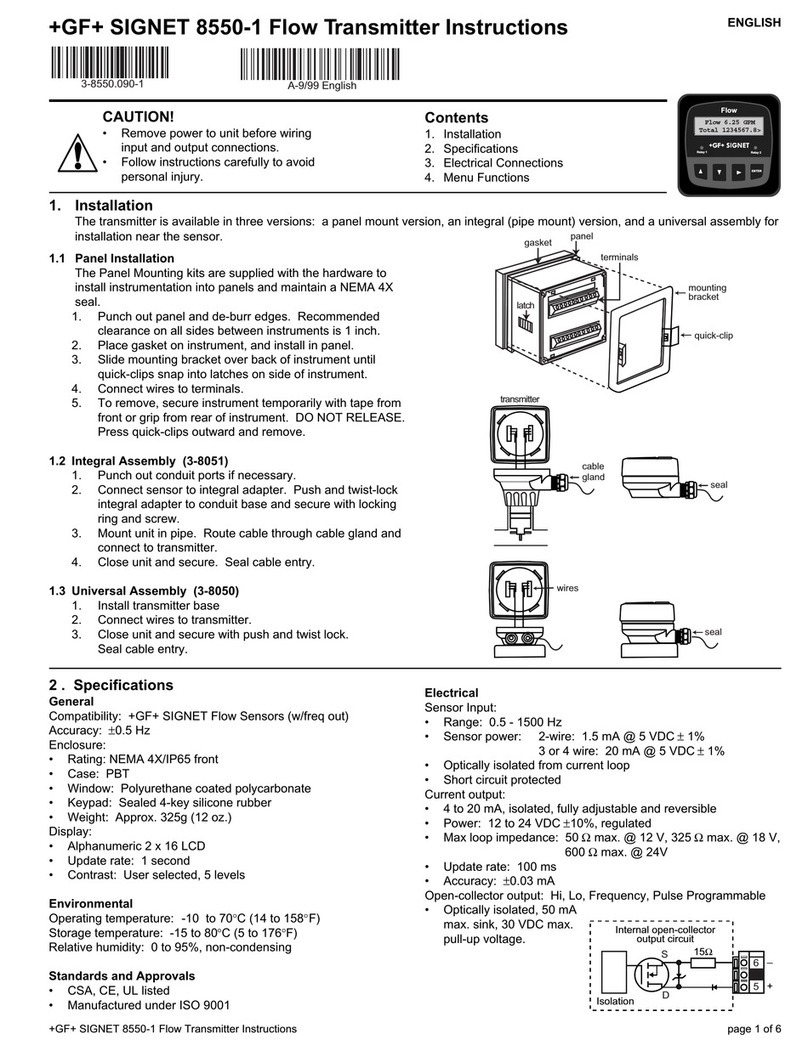

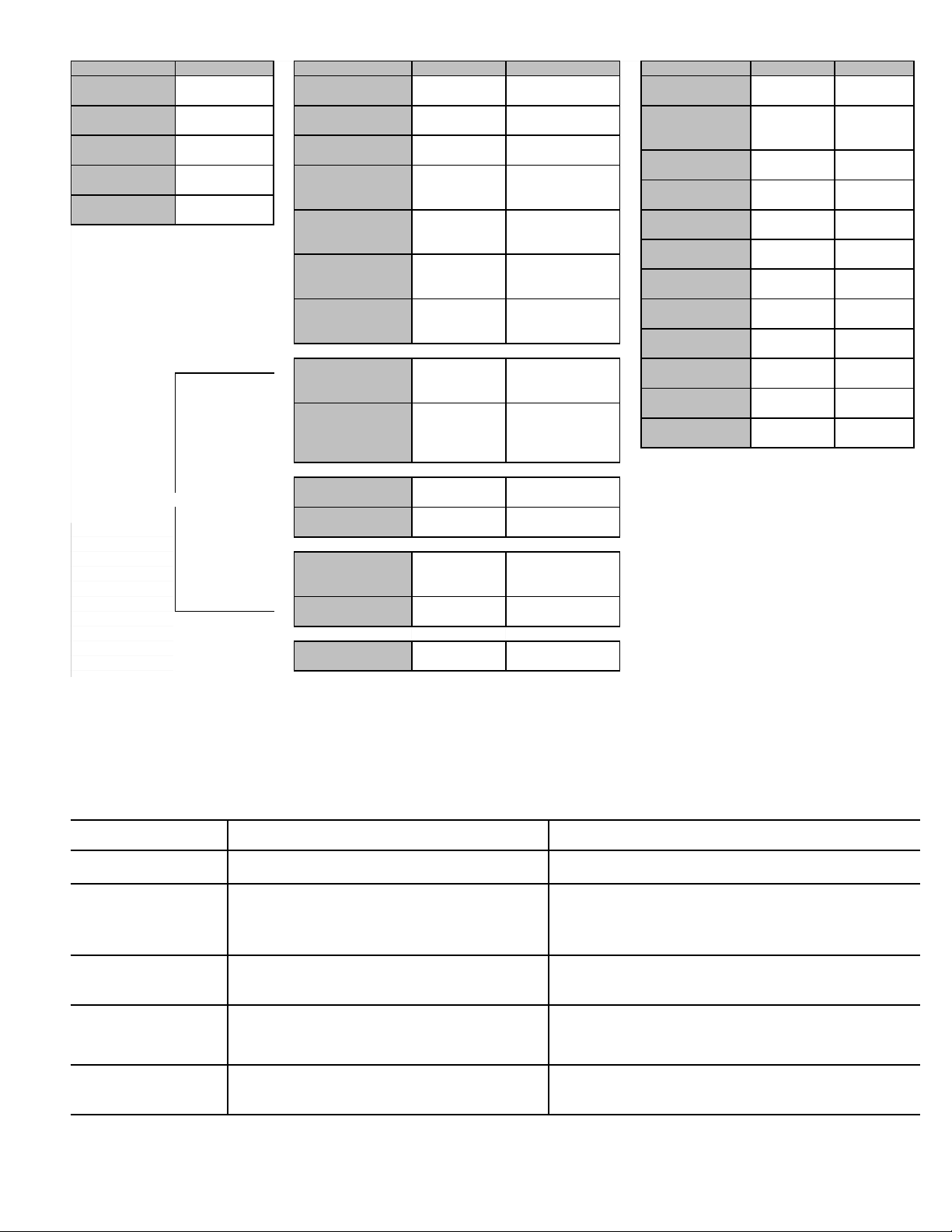

1.1 Panel Installation

The Pane Mounting kits are supp ied with the hardware to

insta instrumentation into pane s and maintain a NEMA 4X

watertight sea .

1. Punch out pane and de-burr edges. Recommended

c earance on a sides between instruments is 1 inch.

2. P ace gasket on instrument, and insta in pane .

3. S ide mounting bracket over back of instrument unti

quick-c ips snap into atches on side of instrument.

4. Connect wires to termina s.

5. To remove, secure instrument temporari y with tape from

front or grip from rear of instrument. DO NOT RELEASE.

Press quick-c ips outward and remove.

1.2 Integral Assembly (3-8052)

1. Punch out conduit ports if necessary.

2. Connect sensor to integra adapter. Push and twist- ock

integra adapter to conduit base and secure with ocking

ring and screw.

3. Mount unit in pipe. Route cab e through cab e g and and

connect to transmitter.

4. C ose unit and secure. Sea cab e entry.

1.3 Universal Assembly (3-8050)

1. Insta transmitter base

2. Connect wires to transmitter.

3. C ose unit and secure with push and twist ock.

Sea cab e entry.

1. Installation

The transmitter is avai ab e in three versions: a pane mount version, an integra (pipe mount) version, and a universa assemb y for

insta ation near the sensor.

Standards and Approvals

• CSA, CE, UL isted

• Manufactured under ISO 9001

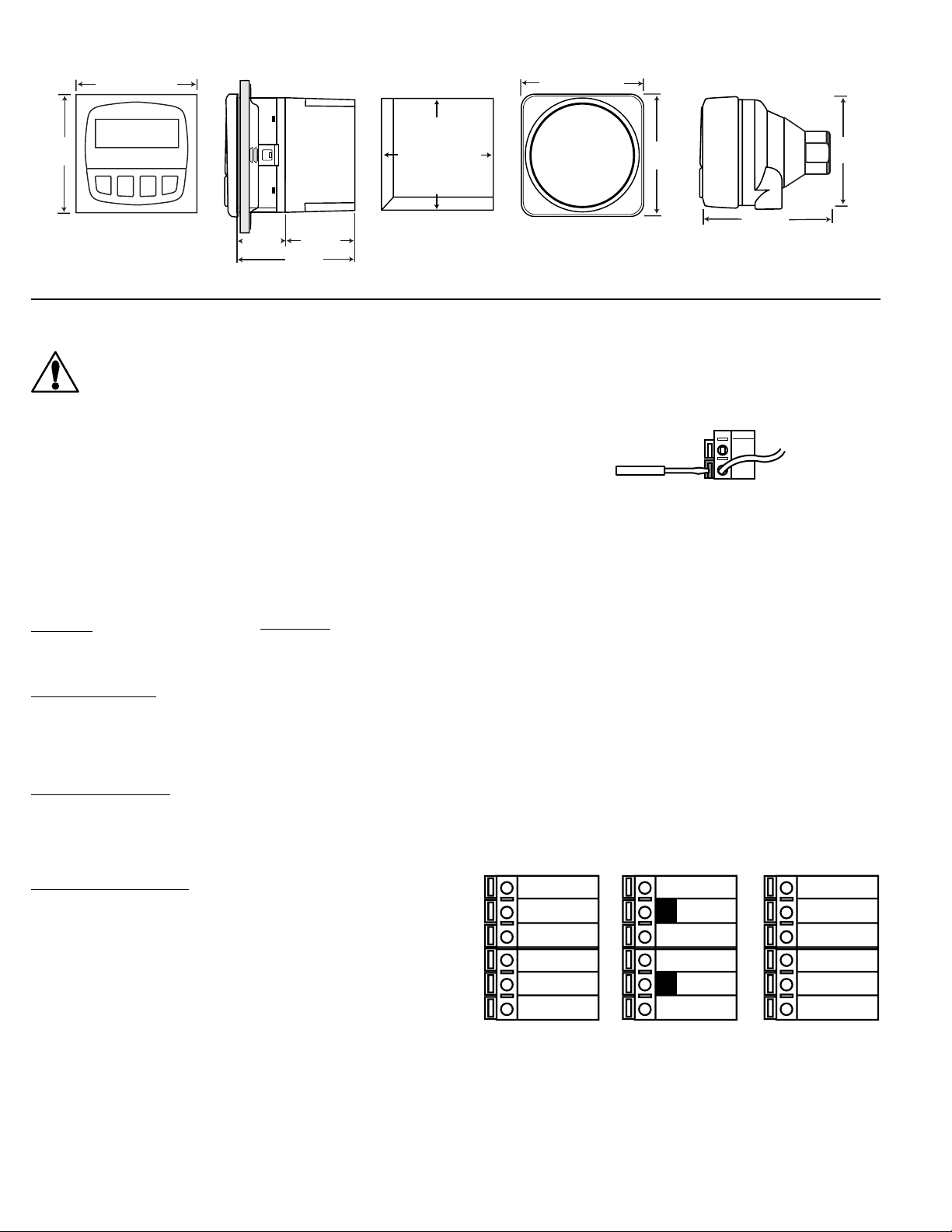

Electrical

Sensor Input: Range: -10 to 100°C

Current outputs (2):

• 4 to 20 mA, iso ated, fu y adjustab e and reversib e

• Power: 12 to 24 VDC ±10%, regu ated, 60 mA max current

• Max oop impedance: 50 Ω max. @ 12 V, 325 Ω max. @ 18 V

600 Ω max. @ 24V

• Update rate: 200 ms

• Accuracy: ±0.03 mA

Open-co ector outputs (2 each): Hi, Lo, Pu se Programmab e

• Open-co ector, iso ated, 50 mA sink or source, 30 VDC max.

pu -up vo tage

• Hysteresis: User adjustab e

2 . Specifications

General

Compatibi ity: +GF+ SIGNET 3-2350-1 or -2 Temperature

Sensors

Accuracy: ±0.5° C

Enc osure:

• Rating: NEMA 4X/IP65 front

• Case: PBT

• Window: Po yurethane coated po ycarbonate

• Keypad: Sea ed 4-key si icone rubber

• Weight: Approx. 325g (12 oz.)

Disp ay:

• A phanumeric 2 x 16 LCD

• Update rate: 1 second

• Contrast: User se ected, 5 eve s

Environmental

Operating temperature: -10 to 70°C (14 to 158°F)

Storage temperature: -15 to 80°C (5 to 176°F)

Re ative humidity: 0 to 95%, non-condensing

1

8

7

Interna open-co ector

output circuit Outputs

Iso ation

15Ω

S

D

2

10

9

_

+

sea

sea

wires

quick-c ip

gasket pane

termina s

mounting

bracket

atch

transmitter

Liquid Tight

Connector

(cab e g and)

B-1/00 Eng ish

3-8350.090-3