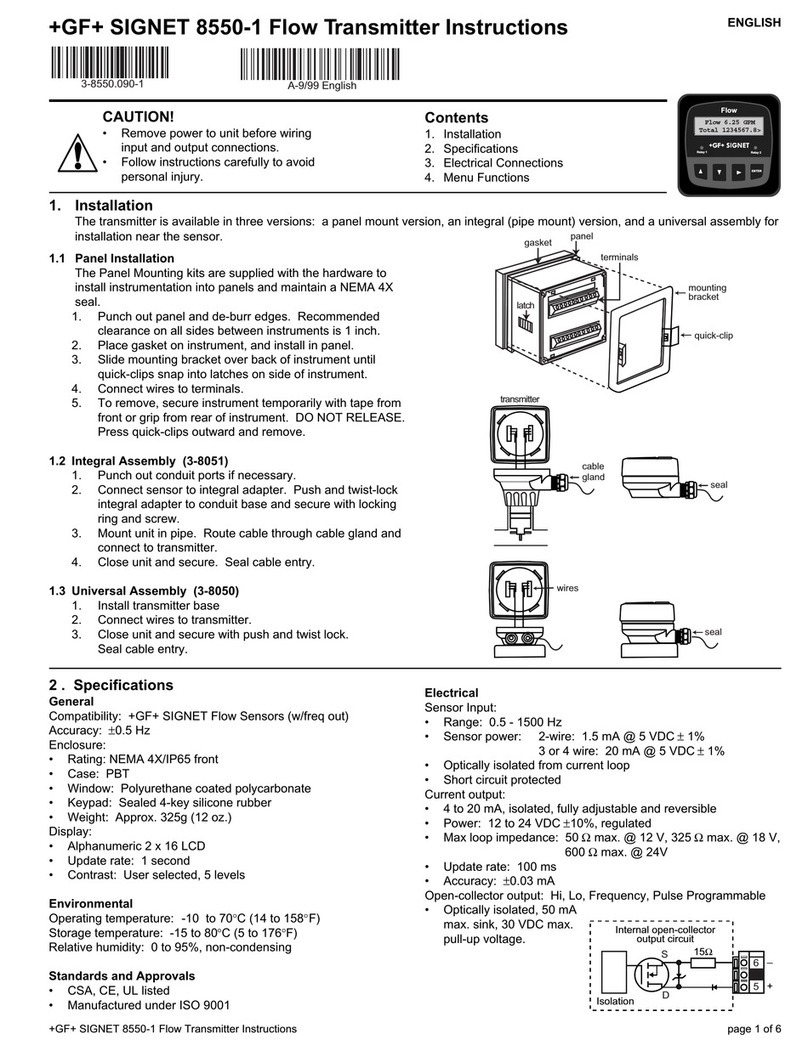

page 1 of 8‡ SIGNET 8450-2 Pressure Transmitter

Pressure

Pressure Cal:

0.0 psi >

Relay 1 Relay 2

ENTER

‡ SIGNET 8450-2 Pressure Transmitter ENGLISH

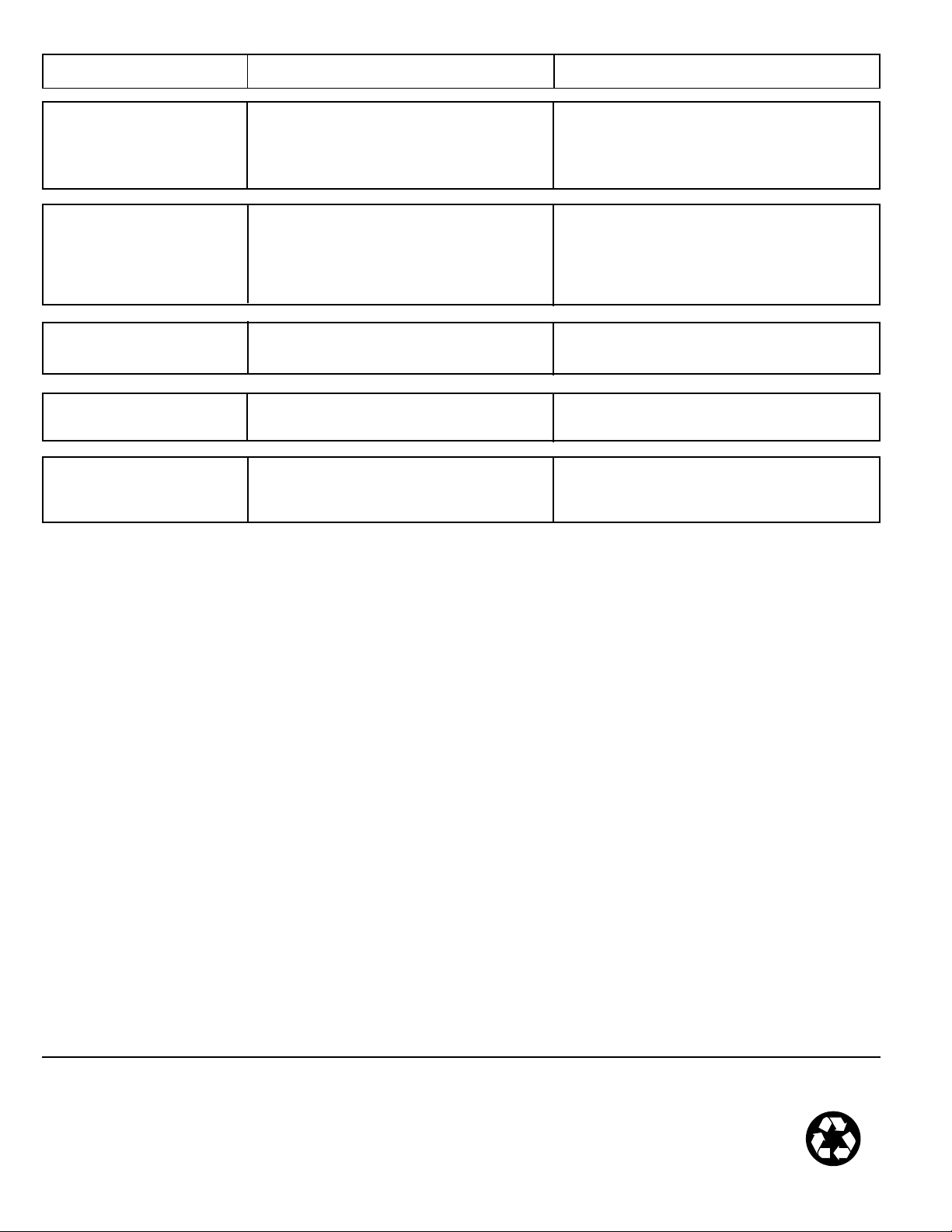

• Max loop impedance:

50 Ω max. 12 V, 325 Ω max. 18 V, 600 Ω max. 24 V

• Update rate: 100 ms

• Accuracy: ±0.03 mA

Relay outputs (2 sets):

• Mechanical SPDT contacts: programmable: Hi, Lo

• Maximum voltage rating: 5 A 30 VDC, 5 A 250 VAC

resistive load

• Hysteresis: User adjustable

Environmental

• Operating temperature: -10 to 70°C (14 to 158°F)

• Storage temperature: -15 to 80°C (5 to 176°F)

• Relative humidity: 0 to 95%, non-condensing

• Maximum altitude: 2000 m (6562 ft)

• Insulation category: II

• Pollution degree: 2

Stan ar s an Approvals

• CSA, CE, UL listed

• Immunity: EN50082-2

• Emissions: EN55011

• Safety: EN61010

• Manufactured under ISO 9001 and ISO 14001

2. Specifications

General

Compatibility: +GF+ SIGNET 2450 Pressure Sensor

Accuracy: ±1% of full scale

Repeatability: ±0.5% of full scale

Enclosure:

• Rating: NEMA 4X/IP65 front

• Case: PBT

• Panel case gasket: Neoprene

• Window: Polyurethane coated polycarbonate

• Keypad: Sealed 4-key silicone rubber

• Weight: Approx. 325g (12 oz.)

Display:

• Alphanumeric 2 x 16 LCD

• Update rate: 1 second

• Contrast: User selected, 5 levels

Electrical

Sensor Input:

• Range: 0-250 psig, 0-17 bar, 0-1700 kPa

Current output:

• 4 to 20 mA, isolated, fully adjustable and reversible

• Power: 12 to 24 VDC ±10%, regulated, 220 mA max current

3-8450.090-2

C-1/01 English

CAUTION!

• Remove power to unit before wiring

input and output connections.

• Follow instructions carefully to avoid

personal injury.

Contents

1. Installation

2. Specifications

3. Electrical Connections

4. Menu Functions

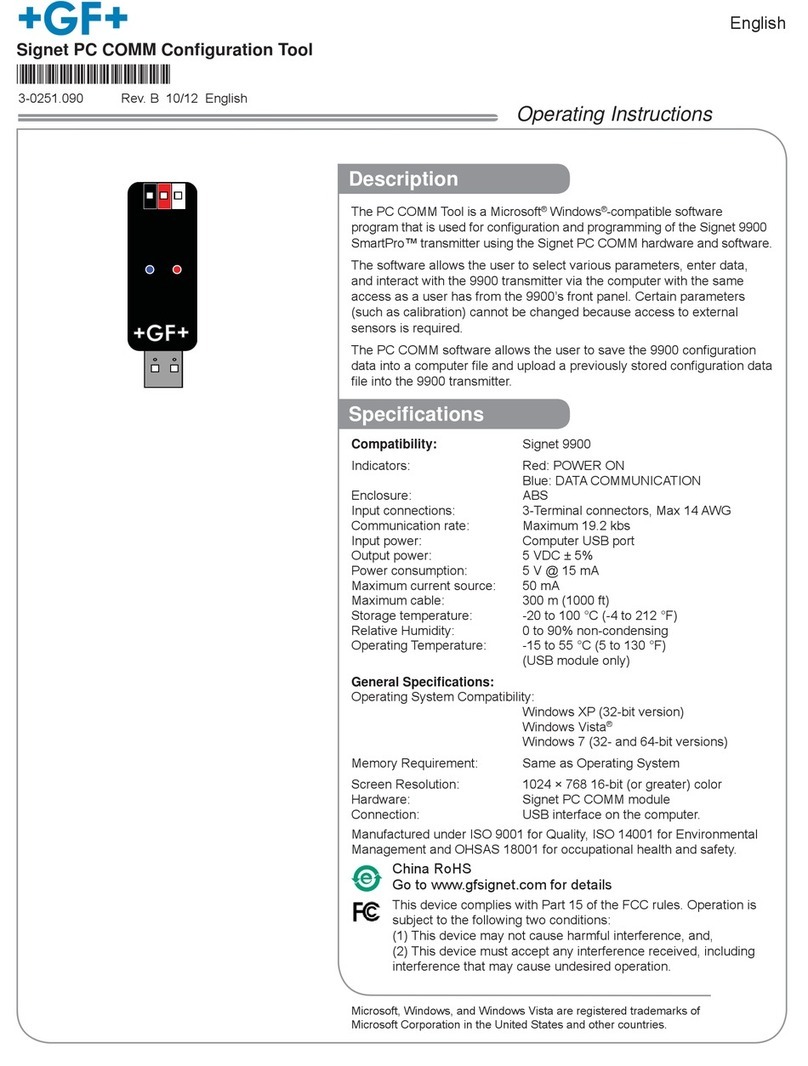

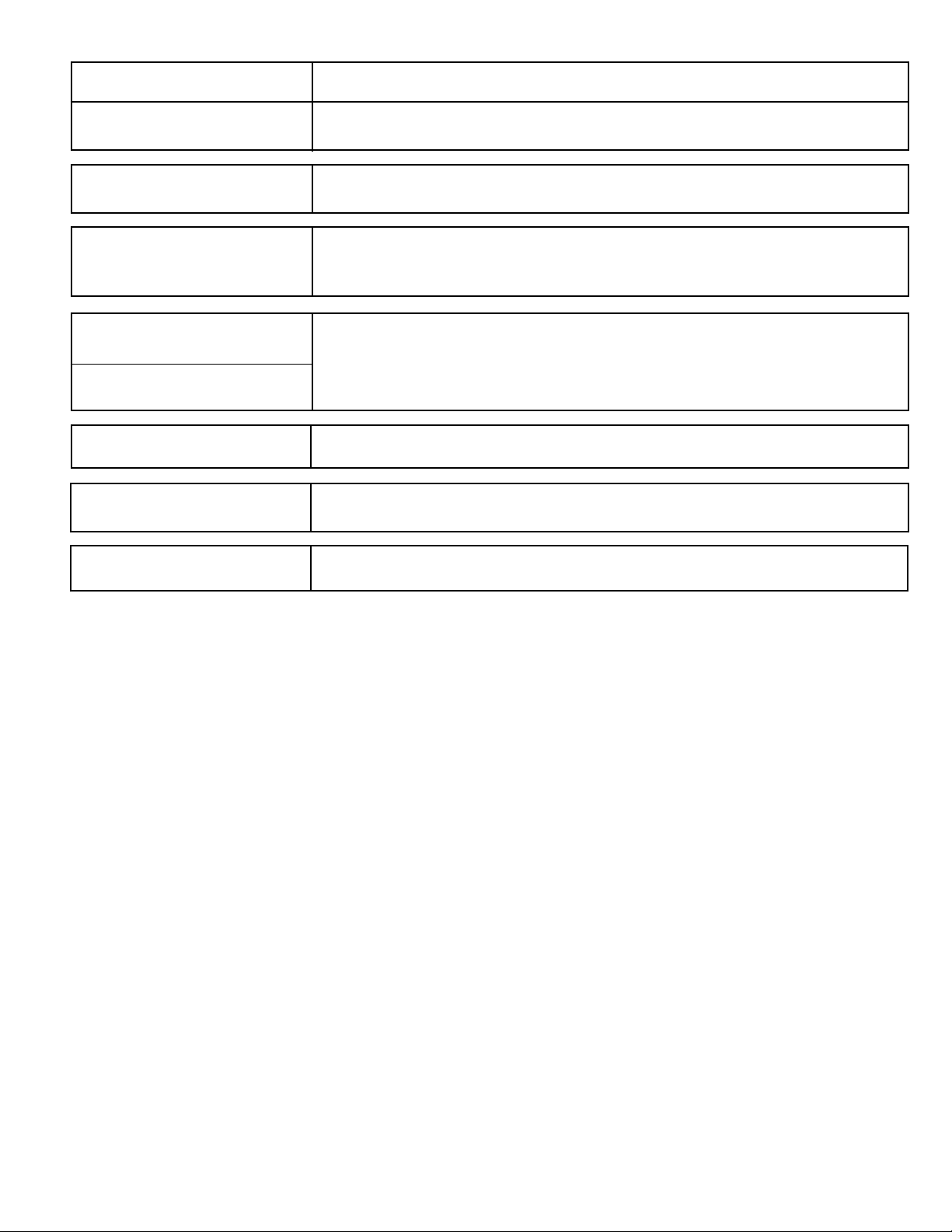

SIDE VIEW

92 mm

(3.6 in.)

97 mm

(3.8 in.)

56 mm

(2.2 in.)

41 mm

(1.6 in.

)

Optional

Rear

Cover

Field Mount Panel Mount

FRONT VIEW

96 mm

(3.8 in.)

96 mm

(3.8 in.)

107 mm

(4.2 in.)

96 mm

(3.8 in.)

quick-clips

gasket panel

terminals mounting

bracket

latch

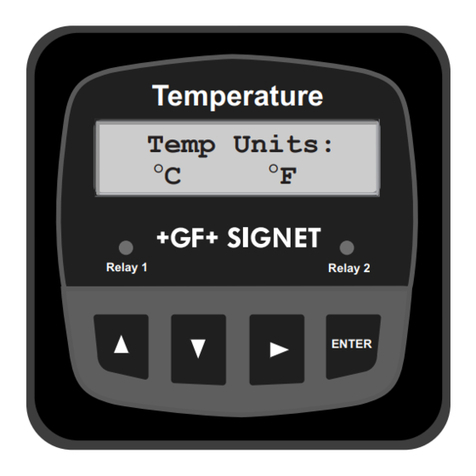

Output -

Output +

System Pwr

Loop -

System Pwr

Loop +

2

14

3

Sensr Gn

(SHIELD)

Sensr IN

(RED)

Sensr V+

(BLACK)

7

6

5

SIDE VIEW

Field Mount &

Panel Mount Panel Mount

Installation Detail

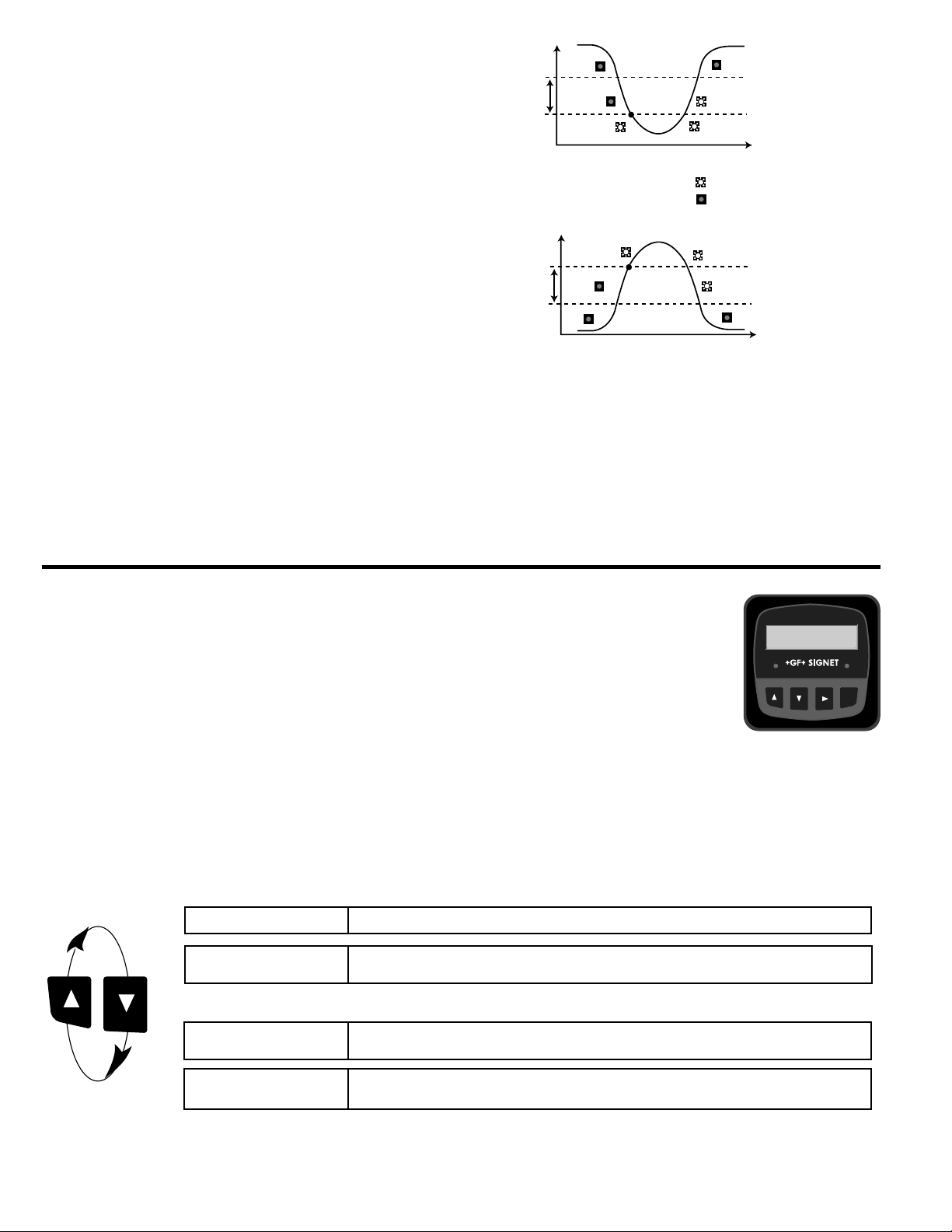

1. Installation

ProcessPro transmitters are available in two styles: panel mount and field mount. The panel mount is supplied with the necessary

hardware to install the transmitter. This manual includes complete panel mounting instructions.

Field mounting requires one of two separate mounting kits. The 3-8052 integral kit joins the sensor and instrument together into a

single package. The 3-8050 Universal kit enables the transmitter to be installed virtually anywhere.

Detailed instructions for integral mounting or other field installation options are included with the 3-8052 Integral kit or the 3-8050

Universal kit.

1.1 Panel Installation

1. The panel mount transmitter is designed for installation using a 1/4 DIN Punch. For manual panel cutout, an adhesive

template is provided as an installation guide. Recommended clearance on all sides between instruments is 1 inch.

2. Place gasket on instrument, and install in panel.

3. Slide mounting bracket over back of instrument until quick-clips snap into latches on side of instrument.

4. To remove, secure instrument temporarily with tape from front or grip from rear of instrument. DO NOT RELEASE.

Press quick-clips outward and remove.