3

1234

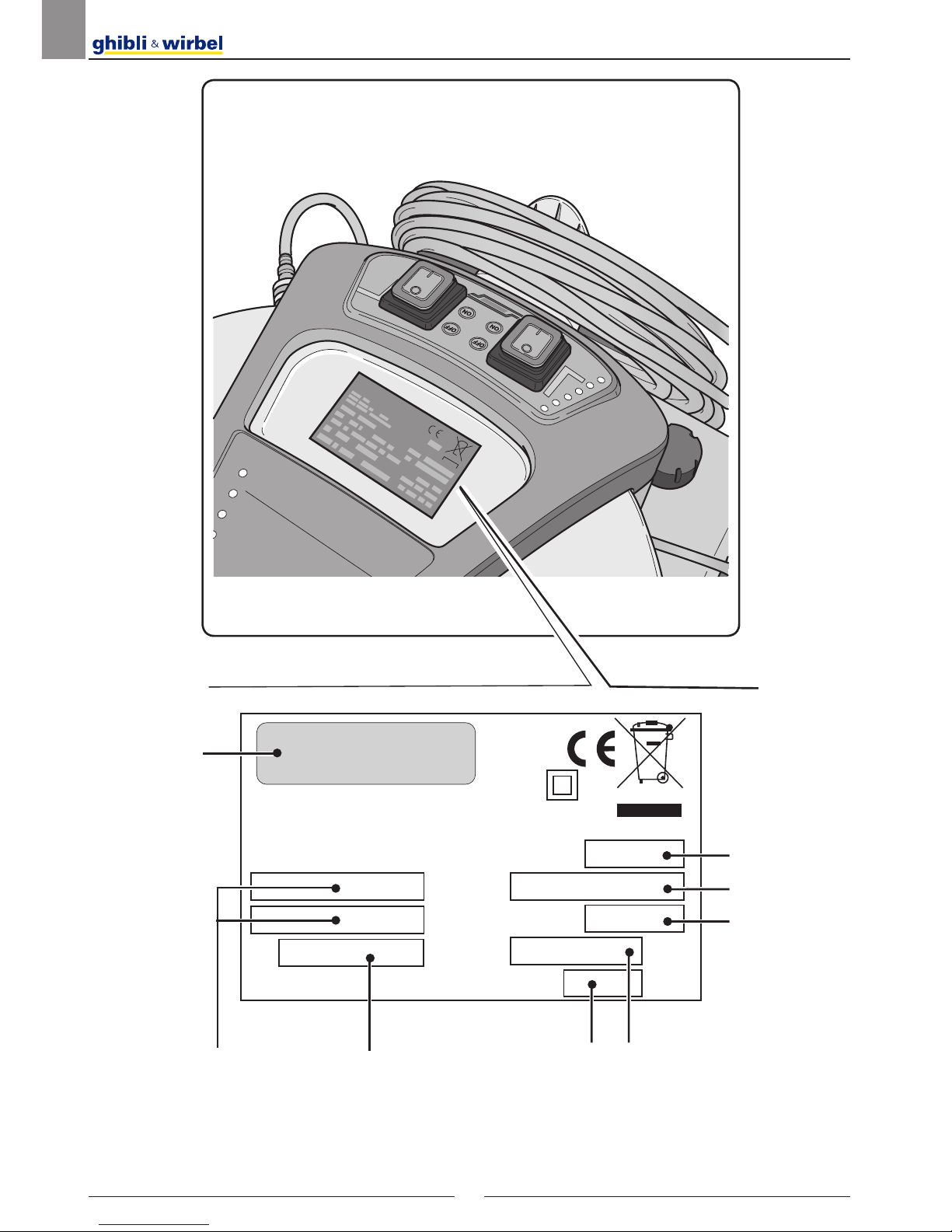

IT Produttore Modello Articolo Capacità fusto

EN Manufacturer Model Article Container capacity

FR Producteur Modèle Article Capacité de la cuve

DE Hersteller Modell Artikel

Fassungsvermögen des Körpers

ES Fabricante Modelo Artículo Capacidad del bidón

PT Produtor Modelo Artigo Capacidade do reservatório

NL Producent Model Artikel Inhoud reservoir

CS Výrobce Model Typ Obsah nádoby

RU

AR

5678

IT Capacità aspirazione Portata d’aria N° Matricola Caratteristiche elettriche

EN Vacuum Air flow Serial N° Electrical characteristics

FR Capacité d’aspiration Débit d’air N° Matricule Caractéristiques électriques

DE Ansaugleistung Luftdurchsatz Matrikelnr. Elektrische Eigenschaften

ES Capacidad de aspiración Caudal de aire N° Matrícola Características eléctricas

PT Capacidade de aspiração Caudal de ar Número de série Características elétricas

NL Zuigcapaciteit Luchtdebiet Serienummer Elektrische eigenschappen

CS Sací výkon

vzduchu Elektrické údaje

RU

AR