EN-6

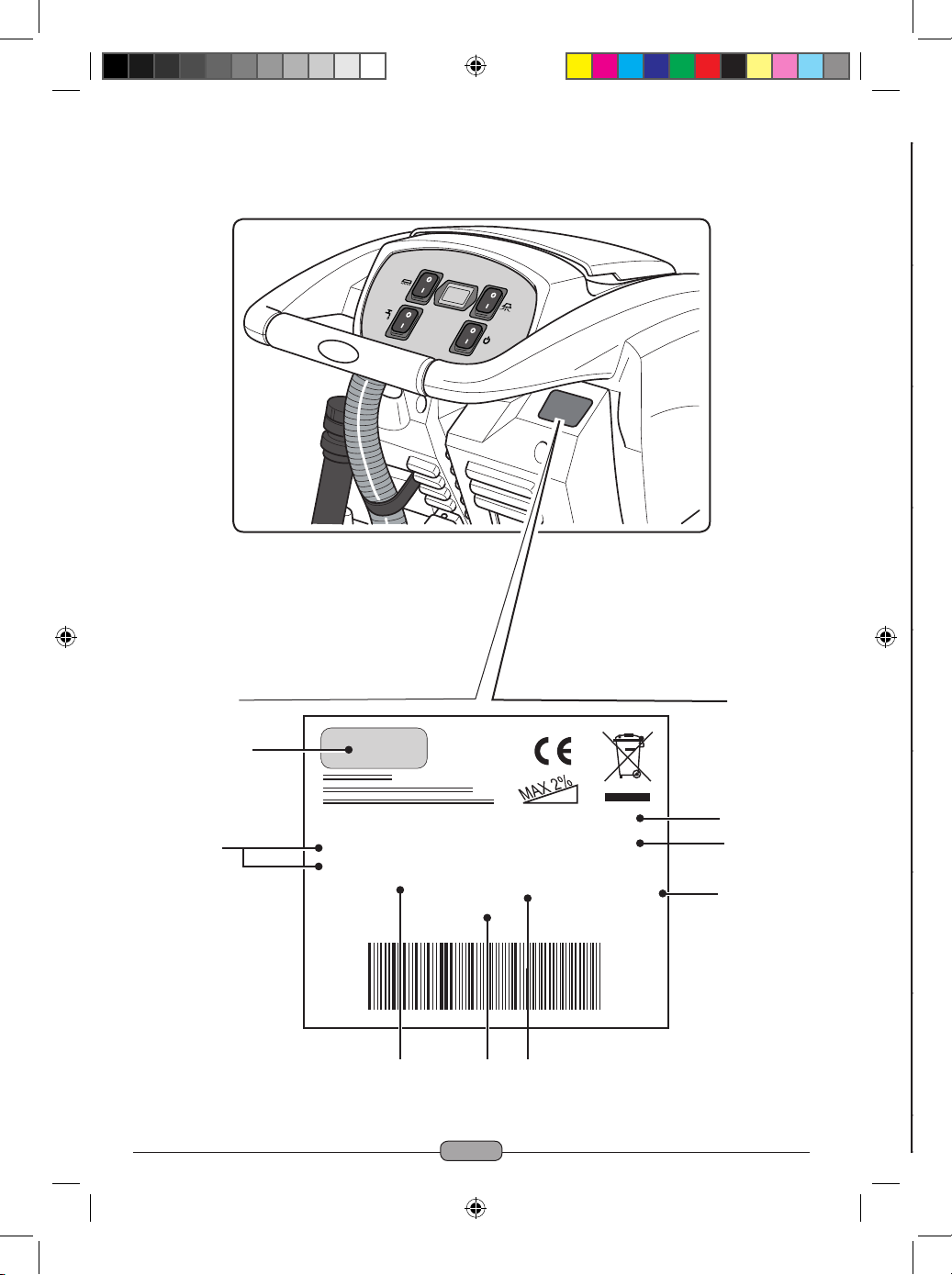

5.1 CONTROL PANEL

(Fig. 9)

20)Sensor for the start of the rotation of

the brush

Acting on the touch sensor (20) with

switch (34) “ ”, the switch (38) “

” and the switch (39) “ ” inserted, it

starts the rotation of the brush and the

water supply.

34)Main switch

With the plug inserted, it lights up, indicat-

ing the presence of voltage.

Pressed in “I” position, it gives the voltage

to other switches.

Pressed on “0” it stops.

35) Suction unit activation switch

The operation of the switch is enabled by

the switch (34) in position “I”.

By pressing the power switch to “I” starts

the operation of the vacuum.

37)Operating hour indicator

Indicates the machine operating hours.

38)Brush rotation enabling switch

Press the switch (38), it enables the ro-

tation of the brush; the operation of the

same is controlled by the touch sensor

(20). To disable the rotation of the brush,

press the switch (38) “ ”.

39)Water solenoid valve switch

The operation of the switch is enabled by

the switch (38) in position “I”.

Press the switch (39), it prepares the

opening of the solenoid water, the ope-

ration thereof is controlled by the touch

sensor (20).

The amount of water is controlled by the

tap (4).

4) Water quantity adjustment tap

Turn the tap (4) counter-clockwise to

increase the quantity of water or turn it

clockwise to decrease it.

6.1 FILLING THE TANK

(Fig. 7)

WARNING:

Only add clean mains water to the tank at

a temperature no greater than 50°C.

- Remove the hose (26) supplied, connect

one end (26a) to a tap and insert the oth-

er end (26b) in the tank (5).

- Check that the tap (40) is open.

- Turn on the tap and fill the tank (5) to the

MAXIMUM LEVEL (NOT EXCEED) indi-

cated by the label placed on the transpar-

ent tube (15).

- Pour the liquid detergent into the tank for

machines not equipped with chemical kit.

N.B.:

Use non-foamy detergents only. For the

quantities, follow the instructions provided by

the detergent manufacturer according to the

type of dirt.

DANGER:

If the detergent comes in contact with the

eyes and/or skin or if swallowed, refer to

the use and safety information booklet

provided by the manufacturer of the de-

tergent.

7.1 OPERATION (Fig. 8)

7.1.a - Checks before use

- Check that the exhaust tube (12) of the

recovery tank is properly coupled and

properly sealed.

- Check that the connector (41) on the

squeegee (11) is not blocked and that the

hose is connected correctly.

- Check that the clean water exhaust tube

(15) is correctly coupled to the supports

and that the tap (40) is open.

7.1.b - Electrical connection

- Introduce the cable (42) of an extension

in the tear-proff hook (28) locking it as

shown in figure.

- Connect the outlet (43) of the extension

cord (42) with the plug (16) of the ma-

chine.

- Connect the power cord to an outlet hav-

ing minimum capacity of 10A.

WARNING:

- Make sure that the mains system is

equipped with an RCD (circuit breaker).

- Unwind the electric power cable com-

pletely before operating the appliance.

- Use an electrical extension lead only

if in perfect condition; ensure that the

section is appropriate for the appliance

power rating.

- Never let the power cable run over

sharp edges and do not tread on it.

7.1.c - Preparing the machine and

choosing the cycle (Figg. 6-9)

- Press the switch (34 Fig. 6).

- Release the lever (3 Fig. 9) and lower it;

theoorsqueegee(11Fig.9)islowered.

- Press down on the pedal (19 Fig. 9), re-

lease it from its coupling and lift it, the

brush (10 Fig. 1) will be lowered.

NOTE:

The brush has two working positions;

Normal position “A”

It is automatically placed when you release

the pedal (19 Fig. 9) from the lifted position.

Position for persistent dirt “B”

From the “A” working position, lift the pedal

(19 Fig. 9) and engage it in the “B1” holder;

an additional pressure of 5 kg will be exer-

cised on the brush.