Giant Industries, Inc.

900 N. Westwood Ave.

Toledo, Ohio 43607

PHONE (419) 531-4600

FAX (419) 531-6836

www.giantpumps.com

© Copyright 2017 Giant Industries, Inc.

08/19 22947-50.indd

Operation

The whole discharge must be guided through the valve. Should the actual operating pressure exceed the adjusted operating pressure, the valve then

acts as a pressure regulator. The valve switches to pressure-free bypass operation when the spray gun shuts off and the spray pressure between

gun and valve remains idle.

The valve can be operated together with several spray guns. It is also possible to connect several pumps to one common discharge line.

IMPORTANT! Valves are NOT SET when delivered. They become a SAFETY COMPONENT only after adjustment on the machine by trained

personnel.

Service and Adjustment

Re-servicing and adjusting work is only to be carried out by skilled tradesmen.

Safety Instructions

Observe direction of ow. The bypass must under no circumstances be closed or tted with any shut-off device.

Continuous bypass operatoin without releasing the water can cause the liquid to heat up which in turn could damage the unit and

endanger persons.

Possible preventive measures:

1.) Limit the bypass duration (max. temperature 140 °F/60 °C); the duration is to be calculated by the operator and in conjunction with the operating

conditions.

2.) Use ttings (e.g. thermal valve on water inlet) to avoid heat increase.

To Adjust Pressure

1.) Open valve so that it is completely tension-free, i. e. loosen nut (24) and adjusting nut (23) so that the piston rod can be moved by hand.

2.) Spring pack is tensioned by adjusting nut (23) while the pump is running and with open gun (if more than one gun is used, all have to be open)

until required operating pressure is attained and no more water runs out on the bypass side. Then lock nut (24) to adjusting nut (23). If the nozzle

hole corresponds exactly to the ow-rate and pressure of the pump, no more water will run out over the bypass after the required pressure has

been attained.

If the nozzle hole is too small and the whole output won’t go through the nozzle after the max. pump pressure has been reached, on no account is

the valve to be adjusted higher than the max. operating pressure of the pump. In this case, the bypass should be partially left open. It is however,

advisable to install suitable nozzles.

To Renew Piston Rod Seals and Sleeves

Unscrew nuts (24+23). Remove spring pack (22). With a 6mm allen wrench, unscrew the 4 inner hexagon screws (20A) and remove spring support

(20). Remove woodruff key (19C) and remove inlet tensioning plug (2). Remove spring (4A), ball (5) and spacer disc (5A). Push out piston rod (18)

downwards together with inner parts (8, and 9). Remove piston body (15) with a size 19 wrench and pull piston rod out of guide case (10). Cut out

worn seals and replace. Then carefully clip O-ring (19A) and support rings (19B) onto the piston rod. Note order of installation. For 22948, 22949 and

22950, put packing (17) on piston rod (18). For 22947, put o-ring (17) and support ring (17A) on piston rod (18). Re-install guide sleeve (10) and

spacer (16). Check casing (1) surfaces and inner parts for dirt or damage as this will cause the seals to wear out quickly. Check O-rings (11&14) and

support rings (12) and replace as necessary. Remount piston body to piston rod with Loctite 648. Re-assemble in reverse order. Grease all parts

lightly with Silicone before reinstalling.

To Check and Replace Valves

Remove the plugs (2) and check whether the balls (5) or valve plate (6) are worn out. Remove valve seats (8, 7) with clipring pliers and check surfaces

for damage. Check O-rings (11) and replace as necessary.

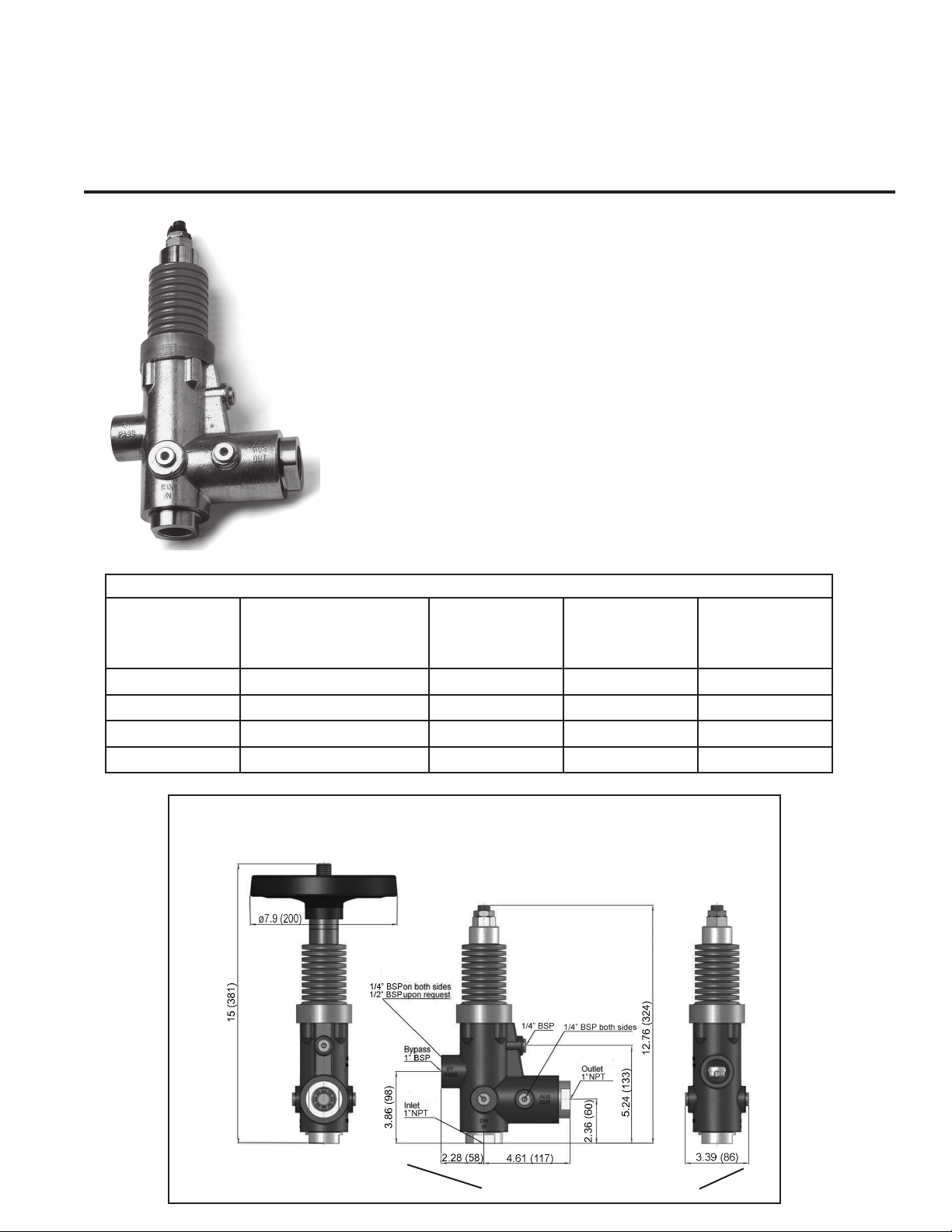

22947(H), 22948(H), 22949(H), 22950(H) Operation and Maintenance

Troubleshooting Guide

Problem Cause Remedy

Valve switched

repeatedly when gun

is closed

Leaky Gun Repair gun

Leaky pressure pipe Seal pressure pipe

Leaky sleeve Replace o-rings

Worn out kick-back valve body Replace kick-back valve body or

o-ring or examine valve seat

Leaky seal (12,14) Renew seal

Leaky piston rod Defective o-ring/support ring Replace piston rod seals and ex-

amine surfaces in guide plug

Leaky bypass at

nominal pressure

nozzle too small, too much water Install larger nozzle

Worn out bypass valve Examine and renew as necessary,

ball (5) and bypass valve body (8)

Pressure Guage

shows high pressure

peaks when shutting

off gun

Valve set too high above operating

pressure

Turn back adjusting nut (23) and

hexagon nut (24) or handwheel

Dirty valve Clean valve (remmoving lime

deposits, etc.) Grease parts before

reinstalling