GIANT ELECTRONICS LTD.

Title: Alignment Procedure

Model: T5025/T5525 Version: 00

THE CONTENT OF THIS DOCUMENT IS GIANT ELCT.LTD. INTELLECTUAL PROPERTY AND IS THE PROPERTY OF GIANT, IT

IS TO BE TREATED AS STRICTLY AND IS NOT BE DISCLOSED, REPRODUCED, OR USED EXCEPT AS AUTHORIZED IN

WRITING BY GIANT ELECTRONIC LTD. IN CONNECTION WITH THE MANUFACTURE, MAINTENANCE AND USE OF THE

GIANT EQUIPMENT WHICH IT PERTAINS. COPYRIGHT @GIANT ELECT. LTD, ALL RIGHTS RESERVED

tuneup.doc 2/5

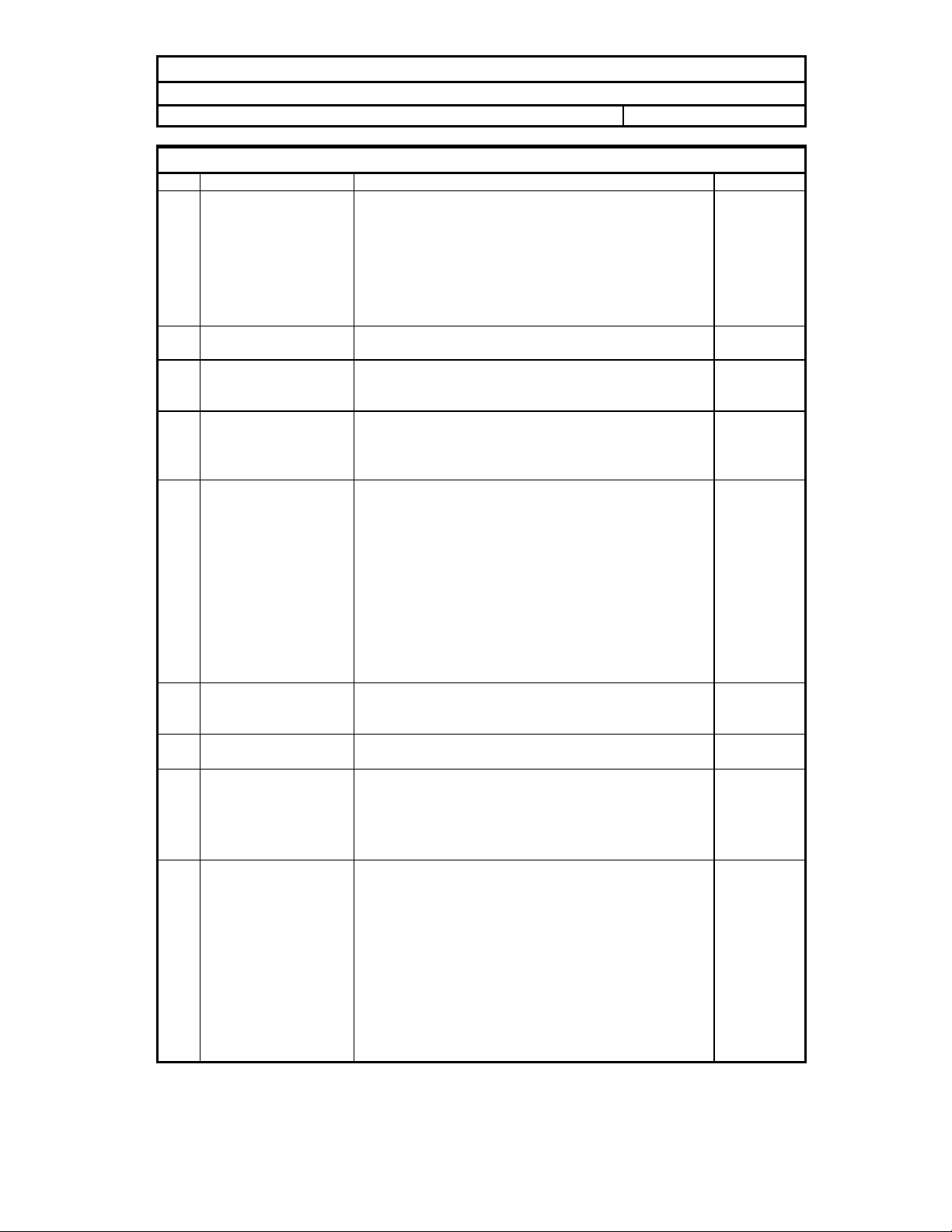

A. PCB LEVEL (Test Condition: under CH8)

NO ITEM ALIGNMENTMETHOD REMARK

10. VOX Detector

(ForT5525)

1.Set VOX level at 1.

2.Set AF level at 15.4 +/-0.2 mV,1KHz at TP116.

3. Unit start to transmit.

4.Set AF level at 13.5 +/-0.2 mV,1KHz at TP116.

5.Unit start to transmit.

6. Set VOX level at 2.

7.Set AF level at 9.4 +/-0.2 mV,1KHz at TP116.

8.Unit start to transmit.

9.Set AF level at 5.8 +/-0.2 mV,1KHz at TP116.

10.Unit start to transmit.

11.Set VOX level at 3.

12.Set AF level at 4.0 +/-0.2 mV,1KHz at TP116.

13.Unit start to transmit.

14.Set AF level at 2.7 +/-0.2 mV,1KHz at TP116.

15.Unit start to transmit.

11. Rx Audio test

1. Set RX mode CH7.

2. Set SG RF level to –50dBm with 1.5KHz deviation

1KHz modulation Signal.

3. Rotate the volume switch to the position, which give a

Max audio output at TP117.

4. Check Max audio output level>1300mV.

5. Check Rx current <150mA.

6. Check the 1KHz distortion <= 5%.

7. Set SG RF level to –119dBm with 1.5kHz deviation at

1KHz audio frequency.

a).Check SINAD sensitivity <= -119dBm.

@12dB SINAD at TP117.

8. Audio frequency response.

a) Set SG RF level to –50dBm with 1.5kHz deviation at

1KHz audio frequency.

b) Rotate the volume switch to the position, which give

an output 100mV±5mV at TP117.

c) Vary the audio frequency from 300Hz to 3KHz.

d) Check the RX response compare to 1KHz tone.

i) 500Hz : +1.0 dB to +5.0 dB .

ii) 2.5KHz : -10.0 dB to–18.0 dB.

9. Maximum and Minimum Audio Output Power.

a) Set SG RF level to –50dBm with 1.5kHz deviation at

1KHz audio frequency.

b) Rotate the volume switch to the position, which give a

maximum output .

c) Check the voltage at TP117 >/=1500mV.

d) Set maximum audio output to 0dB, rotate the volume

switch to the position, which give a minimum output.

e) Check the minimum voltage -23dB to -40dB at TP117

12. Noise-Detector

1. Set SG to –120dBm with 1.5KHz deviation., 1KHz AF

on CH7.

2. Adjust VR102 for transient state @ 10dB SINAD.

3. Check high state @8 to 13dB SINAD.