Giga-tronics 2400 and 2500 Series Microwave Signal Generators

Programming Manual, Part Number 347 3, Rev A, July 2009 i

Table of Contents

Table of Contents........................................................................................................................................... i

Chapter 1. Safety ....................................................................................................................................1

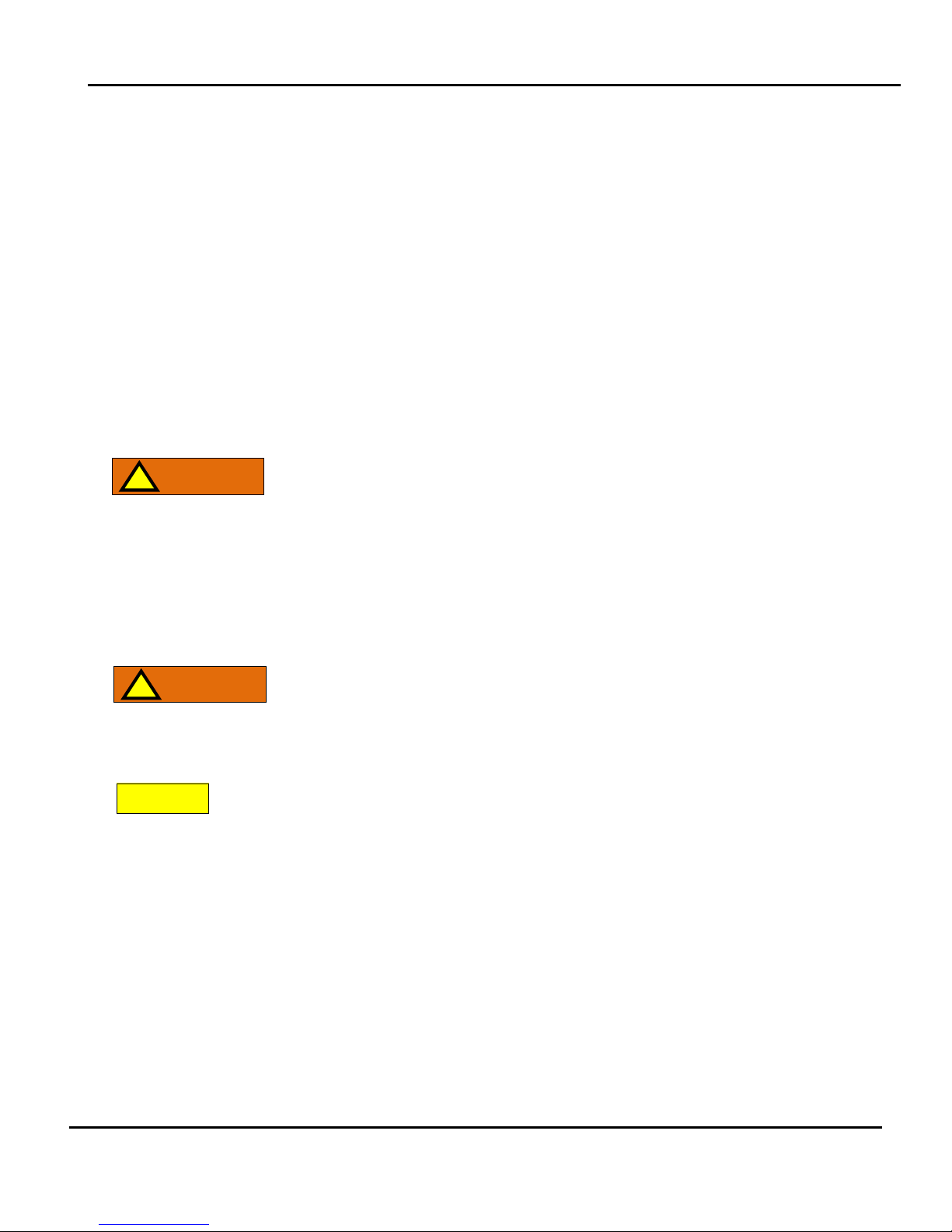

1.1 Unsafe Operating Conditions........................................................................................................1

1.2 Safety Warnings Used in This Manual ..........................................................................................1

1.2.1 Personal Safety Alert.............................................................................................................1

1.2.2 Equipment Safety Alert.........................................................................................................1

1.2.3 Notes.....................................................................................................................................1

Chapter 2. Introduction ..........................................................................................................................3

2.1 Overview .......................................................................................................................................3

2.2 Physical Description of the 2400/2500.........................................................................................4

Chapter 3. Hardware Interfaces .............................................................................................................5

3.1 Introduction ..................................................................................................................................5

3.2 Configure the 2400/2500 Hardware Interface .............................................................................6

3.2.1 Using the Included USB Cable...............................................................................................6

3.2.2 Assign a GPIB Address to the 2400/2500..............................................................................6

3.2.3 Configure the Computer’s RS-232 for Remote Operation....................................................6

3.2.4 Configure the 2400/2500 Ethernet Connection ...................................................................7

Chapter 4. Programming Interfaces .......................................................................................................9

4.1 Introduction ..................................................................................................................................9

4.2 Select the Remote Programming Language..................................................................................9

4.3 Dynamic Link Library (DLL)..........................................................................................................10

4.3.1 Adding the DLL to Programming Projects...........................................................................10

4.3.2 Programming Examples Using the DLL ...............................................................................11

4.3.3 DLL Functions ......................................................................................................................17

4.4 SCPI Command Set......................................................................................................................96

4.4.1 SCPI Command Format .......................................................................................................96

4.4.2 SCPI Commands ..................................................................................................................97

4.5 IEEE 4 .2 Common Commands...............................................................................................120

4.6 GT-12000 Native Commands ....................................................................................................122

4.6.1 GT-12000 Native Commands: CW and System.................................................................122

4.6.2 GT-12000 Native Commands: List Mode ..........................................................................123

4.6.3 GT-12000 Native Commands: Amplitude Modulation .....................................................125

4.6.4 GT-12000 Native Commands: Frequency Modulation .....................................................126

4.6.5 GT-12000 Native Commands: Phase Modulation.............................................................127

4.6.6 GT-12000 Native Commands: Pulse Modulation..............................................................12

4.7 Emulation..................................................................................................................................129

4.7.1 HP 34X Emulation Commands ........................................................................................129