CABK-ASOM-735x-01

INCAM-G Operator’s Manual Page 2 of 25

CONTENTS

1 General information ................................................................................................................. 3

1.1 General Safety Information .............................................................................................. 3

1.2 Disposal Instructions ....................................................................................................... 3

1.3 Environmental ................................................................................................................. 3

1.4 Health & Safety................................................................................................................ 4

1.5 Maximum RF Power Density Limits ................................................................................. 5

1.6 Document Issue Status.................................................................................................... 5

2 Introduction ............................................................................................................................. 6

3 Specifications .......................................................................................................................... 8

4 Installing the INCAM-G onto the camera ............................................................................... 10

5 INCAM-G operation ............................................................................................................... 11

5.1 On / Standby / Off switch ............................................................................................... 11

5.2 Connectors and Pin outs ............................................................................................... 11

5.2.1 Rear Connectors........................................................................................................ 11

5.2.1.1 Telemetry Antenna (1) ....................................................................................... 11

5.2.1.2 Video Out (2) ..................................................................................................... 12

5.2.1.3 Power In (3) ....................................................................................................... 12

5.2.1.4 Power Switch (4) ................................................................................................ 12

5.2.1.5 Steadicam Tally (5) ............................................................................................ 12

5.2.1.6 Return Data (6) .................................................................................................. 12

5.2.1.7 External Audio (7) .............................................................................................. 12

5.2.1.8 Remote Configuration (8) ................................................................................... 13

5.2.1.9 RF Antenna (9) .................................................................................................. 13

5.2.2 Side Connectors ........................................................................................................ 14

5.2.2.1 Return In (1) ....................................................................................................... 14

5.2.2.2 SDI Out (2) ......................................................................................................... 14

5.2.3 Transmitter Configuration via Windows PC application .............................................. 15

6 Camera control ...................................................................................................................... 17

6.1 Associated documentation ............................................................................................. 17

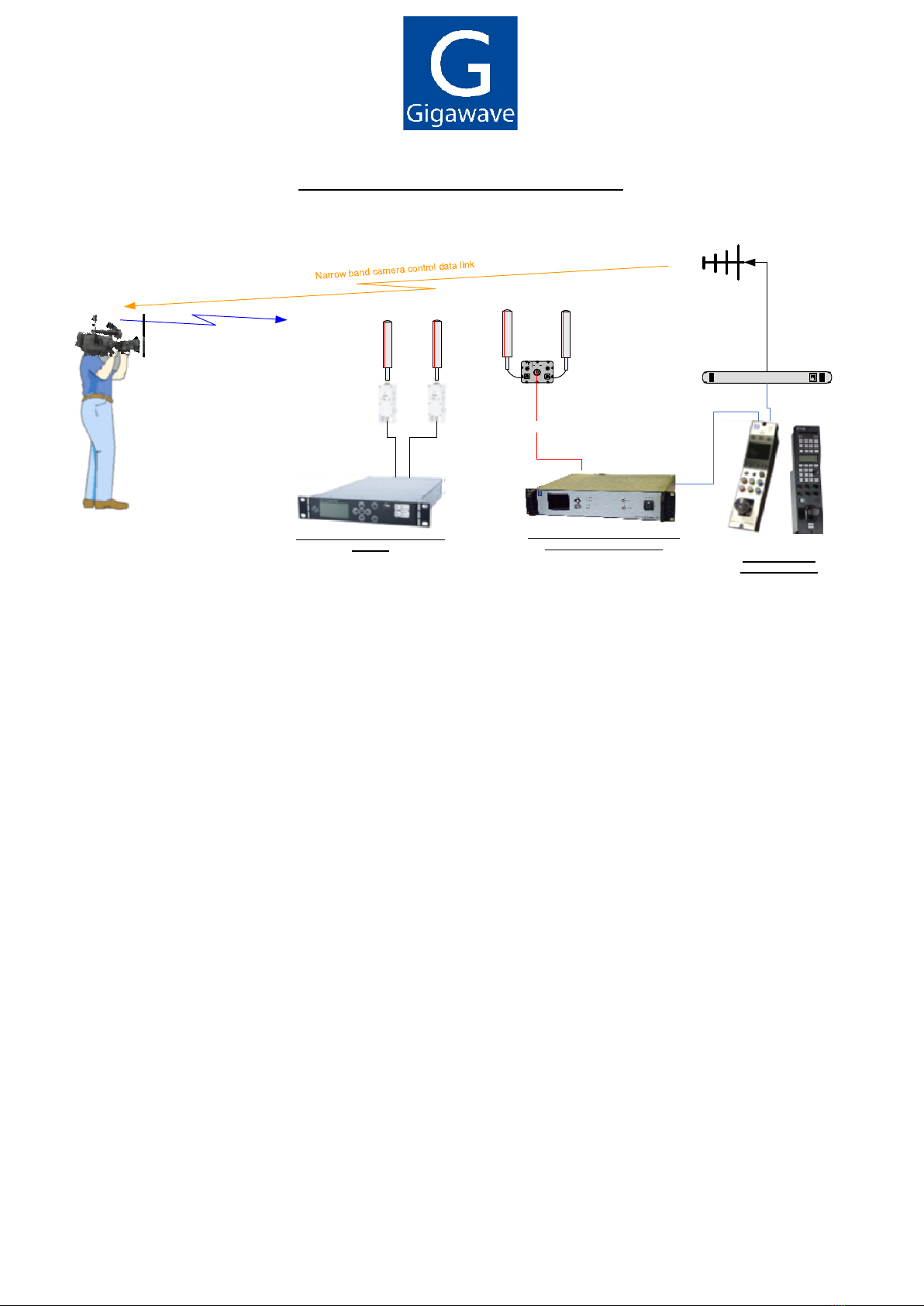

6.2 Typical block diagrams .................................................................................................. 17

6.2.1 MVL-HD3 receiver with built in Camera control TX .................................................... 17

6.2.2 MVL-HD3 receiver with separate Camera control TX ................................................. 18

6.2.3 MTV-HD3 receiver ..................................................................................................... 19

6.2.4 Interconnection details, when Interface Unit............................................................... 20

6.2.5 Arrangement for multiple OCPs and Cameras, using a single Data TX ...................... 21

7 Preparing for operation .......................................................................................................... 22

7.1 The INCAM-G transmitter .............................................................................................. 22

7.2 The Receiving Equipment .............................................................................................. 22

8 Table of COFDM bit rates...................................................................................................... 23

8.1 DVB-T bit rates .............................................................................................................. 23

8.2 LMS-T Bit rates.............................................................................................................. 24

9 Internal Architecture Block Diagram ...................................................................................... 25