3 / 41

CONTENTS

1. INTRODUCTION ...........................................................................................................................................................4

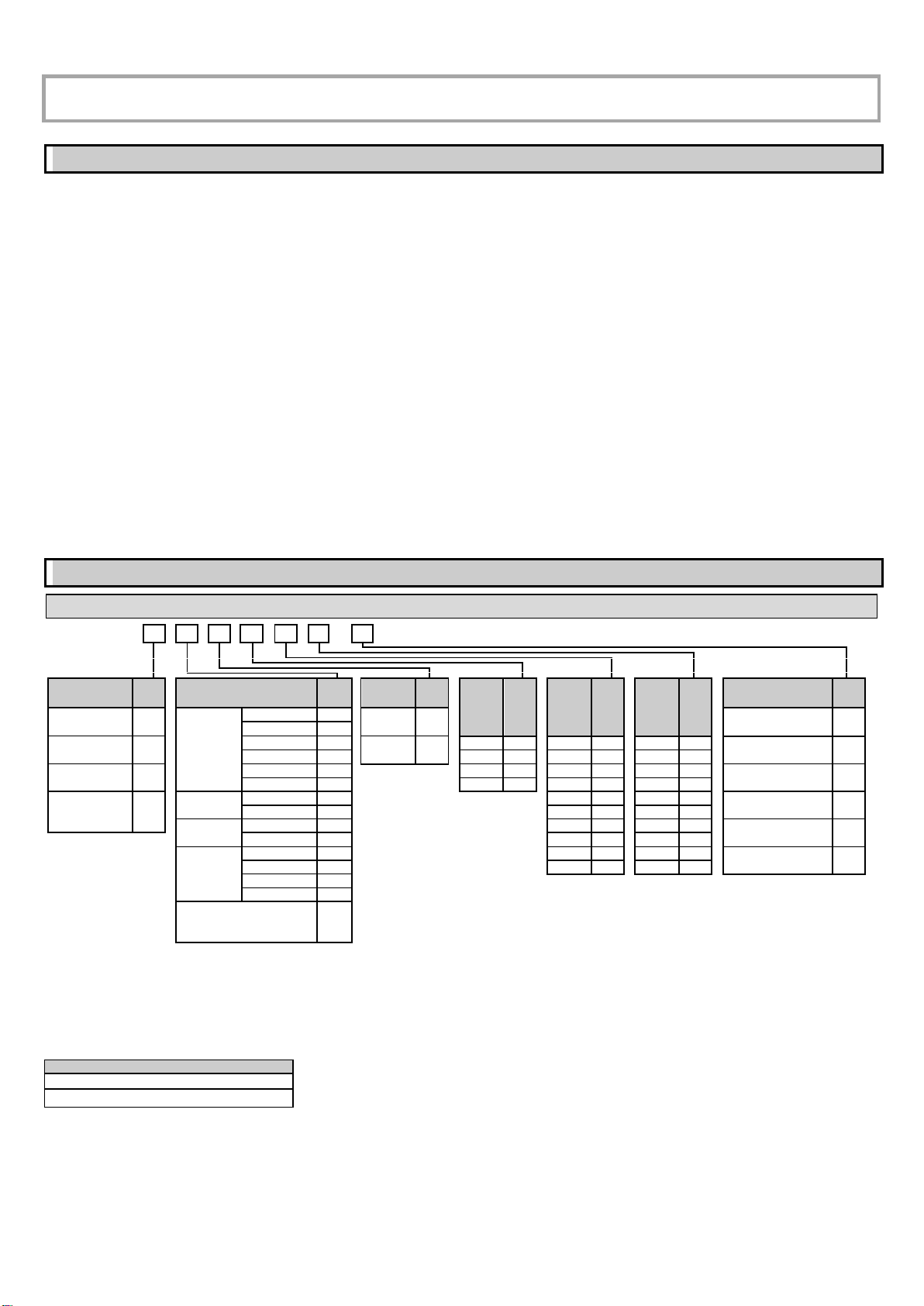

2. ORDER CODES (NOT ALL COMBINATIONS POSSIBLE) ...................................................................................................4

2.1. VF05 -WITH CABLE PROBE .....................................................................................................................................................4

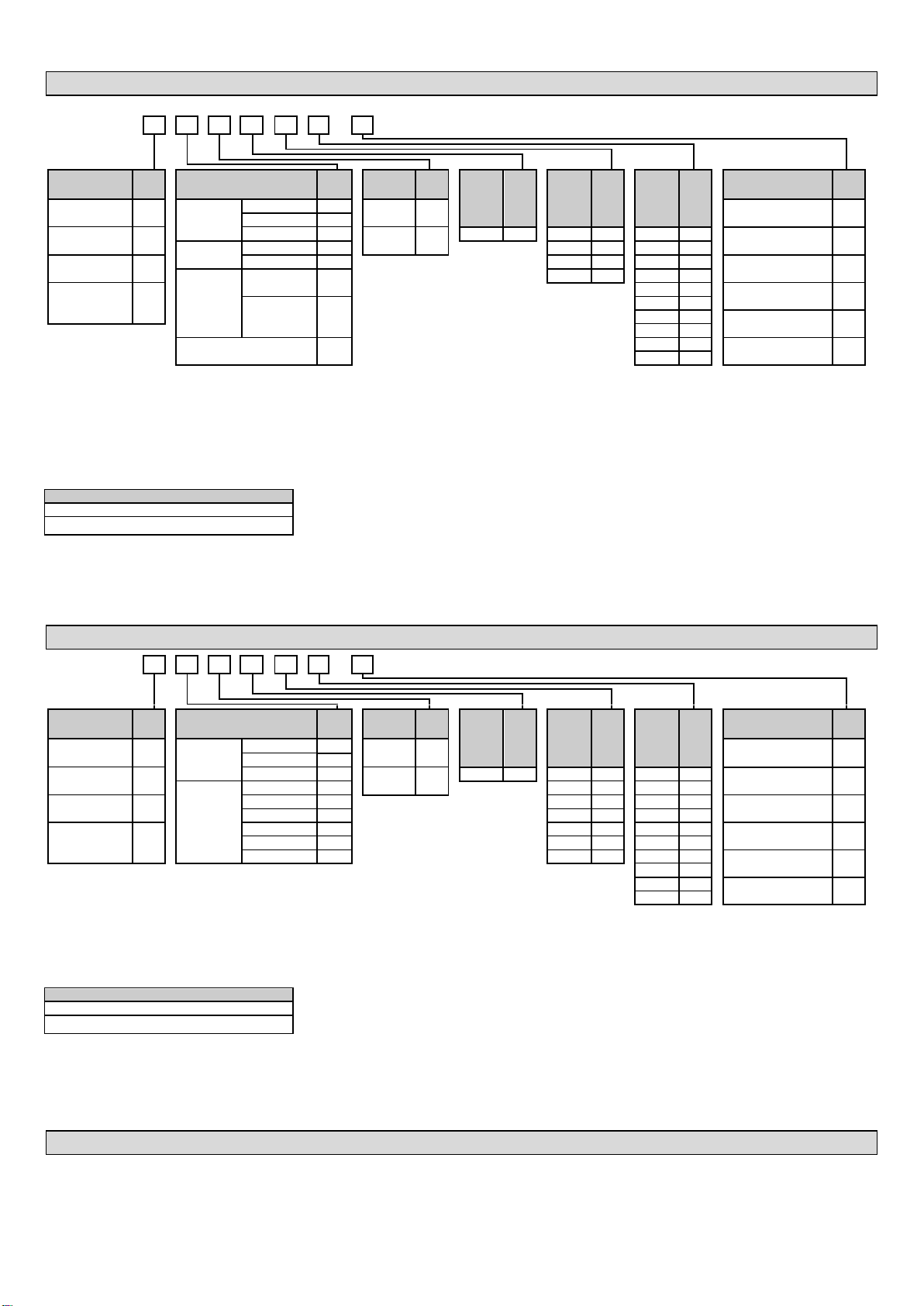

2.2. VF05 -WITH ROD PROBE .......................................................................................................................................................5

2.3. VF05 –WITH ROD PROBE OR COAXIAL ROD PROBE ......................................................................................................................5

2.4. ACCESSORIES........................................................................................................................................................................5

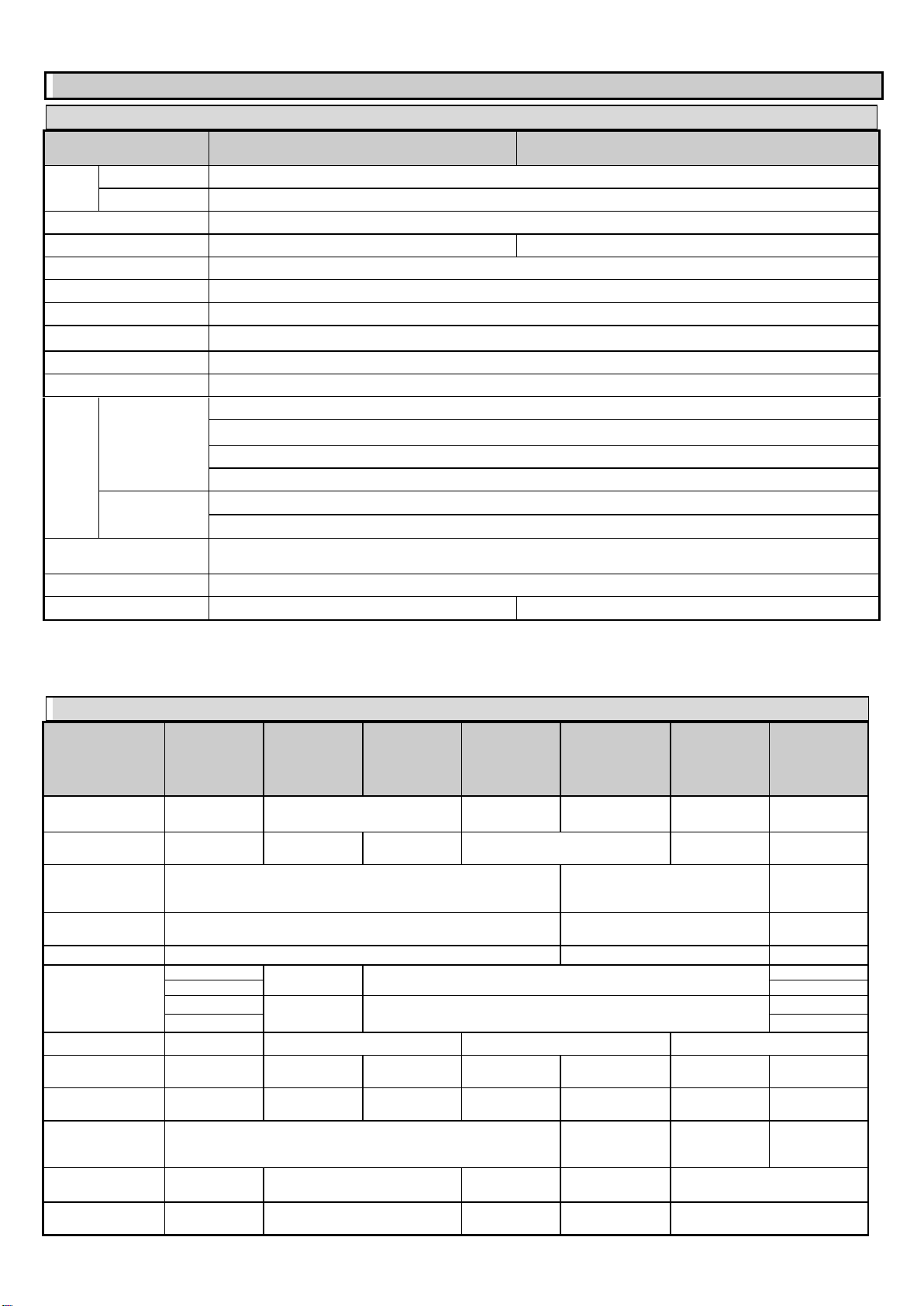

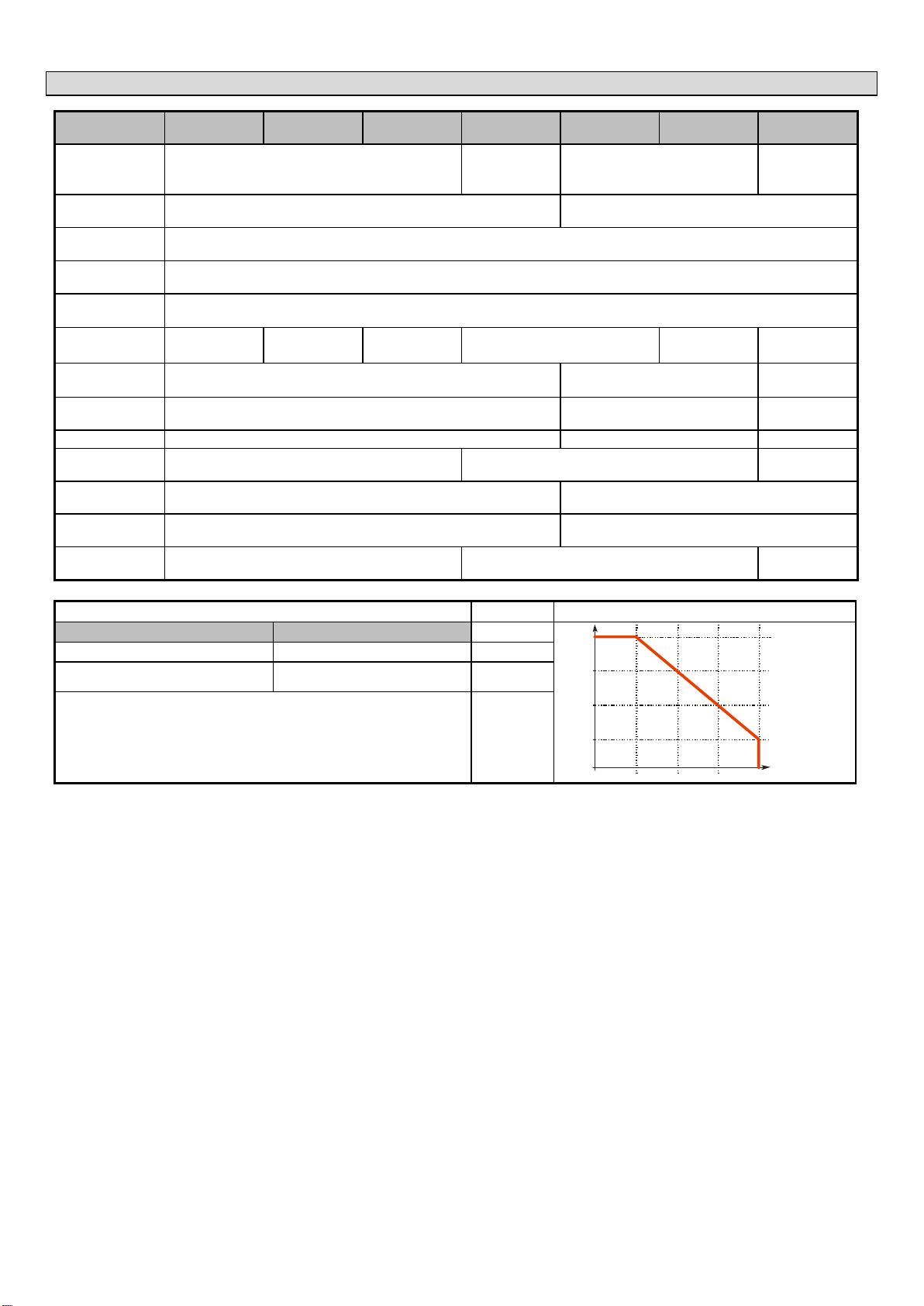

3. TECHNICAL DATA.........................................................................................................................................................6

3.1. GENERAL.............................................................................................................................................................................6

3.2. PROBE PROPERTIES................................................................................................................................................................6

3.3. COATED PROBE PROPERTIES ....................................................................................................................................................7

3.4. DIMENSIONS........................................................................................................................................................................8

3.5. ATEX INFORMATION (FOR PRODUCTS CODES ENDING WITH EX).....................................................................................................9

3.5.1. ATEX General ............................................................................................................................................................9

3.5.2. ATEX nameplate........................................................................................................................................................9

3.5.3. ATEX Intrinsically safe protection (Ex ia)...................................................................................................................9

3.5.4. Temperature limit data for ATEX (Ex ia) approved models.....................................................................................10

3.5.5. ATEX explosive dust protection (Ex t)......................................................................................................................10

3.5.6. Temperature limit data for ATEX (Ex t) approved models ......................................................................................10

3.6. CONDITIONS FOR SAFE USE (INCLUDES ATEX)..........................................................................................................................11

3.7. MAINTENANCE AND REPAIR..................................................................................................................................................11

4. INSTALLING ...............................................................................................................................................................12

4.1. HANDLING AND STORAGE.....................................................................................................................................................12

4.2. MOUNTING ON CONTAINERS.................................................................................................................................................12

4.2.1. General mounting instructions ...............................................................................................................................12

4.2.2. Installing the Device for Measuring Solids ..............................................................................................................14

4.3. WIRING ............................................................................................................................................................................15

4.3.1. Design of the measuring network in non-explosive environments .........................................................................15

4.3.2. Connection in explosive environment .....................................................................................................................16

4.3.3. BUS (HART®) communication ..................................................................................................................................16

4.4. SWITCHING ON AND COMMISSIONING ....................................................................................................................................16

4.5. AVAILABLE USER INTERFACES ................................................................................................................................................16

5. PROGRAMMING........................................................................................................................................................17

5.1. PROGRAMMING WITH HYVIEW..............................................................................................................................................17

5.1.1. Installing and Running HyView ...............................................................................................................................17

5.1.2. Programming and Configuring the Device..............................................................................................................21

5.1.3. Programming Examples using HyView ...................................................................................................................32

5.2. PROGRAMMING WITH THE VGF-DISPLAY UNIT.......................................................................................................................33

5.2.1. VGF-DISPLAY Unit ...................................................................................................................................................33

5.2.2. The Behaviour of the VF05 while Programmed Manually ......................................................................................33

5.2.3. Manual Programming.............................................................................................................................................33

5.3. PROPERTIES OF VF05 TWO-WIRE MICROWAVE LEVEL TRANSMITTER ...........................................................................................35

5.3.1. Level Measurement –Level reflection, Threshold Line and Automatic Gain Adjustment.......................................35

5.3.2. To illustrate the five possible configurations, the following fluid level measurement settings are assumed .........36

5.3.3. Echo Loss Handling .................................................................................................................................................36

5.3.4. Typical Signal Forms ...............................................................................................................................................38

5.4. TROUBLESHOOTING.............................................................................................................................................................39