Emerson Rosemount 2051CF series User manual

Other Emerson Transmitter manuals

Emerson

Emerson Rosemount 3051 User manual

Emerson

Emerson Rosemount 648 User manual

Emerson

Emerson Rosemount 3051 User manual

Emerson

Emerson Rosemount OCX 8800 User manual

Emerson

Emerson Rosemount 702 User manual

Emerson

Emerson Rosemount 3100 Series User manual

Emerson

Emerson Rosemount 2051 User manual

Emerson

Emerson Rosemount 1056 User manual

Emerson

Emerson Rosemount 3051HT User manual

Emerson

Emerson MICRO MOTION 1500 User manual

Emerson

Emerson Micro Motion 9739 MVD Quick guide

Emerson

Emerson Rosemount 2051G User manual

Emerson

Emerson Rosemount OCX 8800 User manual

Emerson

Emerson Rosemount 644 User manual

Emerson

Emerson Rosemount 1208A User manual

Emerson

Emerson Rosemount X-well 648 User manual

Emerson

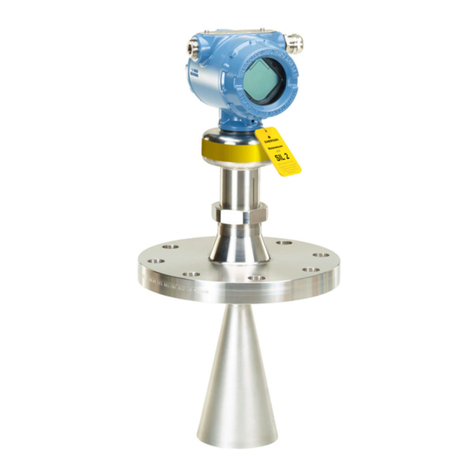

Emerson Rosemount 5408 User manual

Emerson

Emerson ROSEMOUNT 5300 Configuration guide

Emerson

Emerson Rosemount 2240S User manual

Emerson

Emerson Rosemount 248 User manual

Popular Transmitter manuals by other brands

Dejero

Dejero EnGo 3x manual

Rosemount

Rosemount 4600 Reference manual

Speaka Professional

Speaka Professional 2342740 operating instructions

trubomat

trubomat GAB 1000 instruction manual

Teledyne Analytical Instruments

Teledyne Analytical Instruments LXT-380 instructions

Rondish

Rondish UT-11 quick start guide