3

160 T

20 T 40 T

60 T 80 T

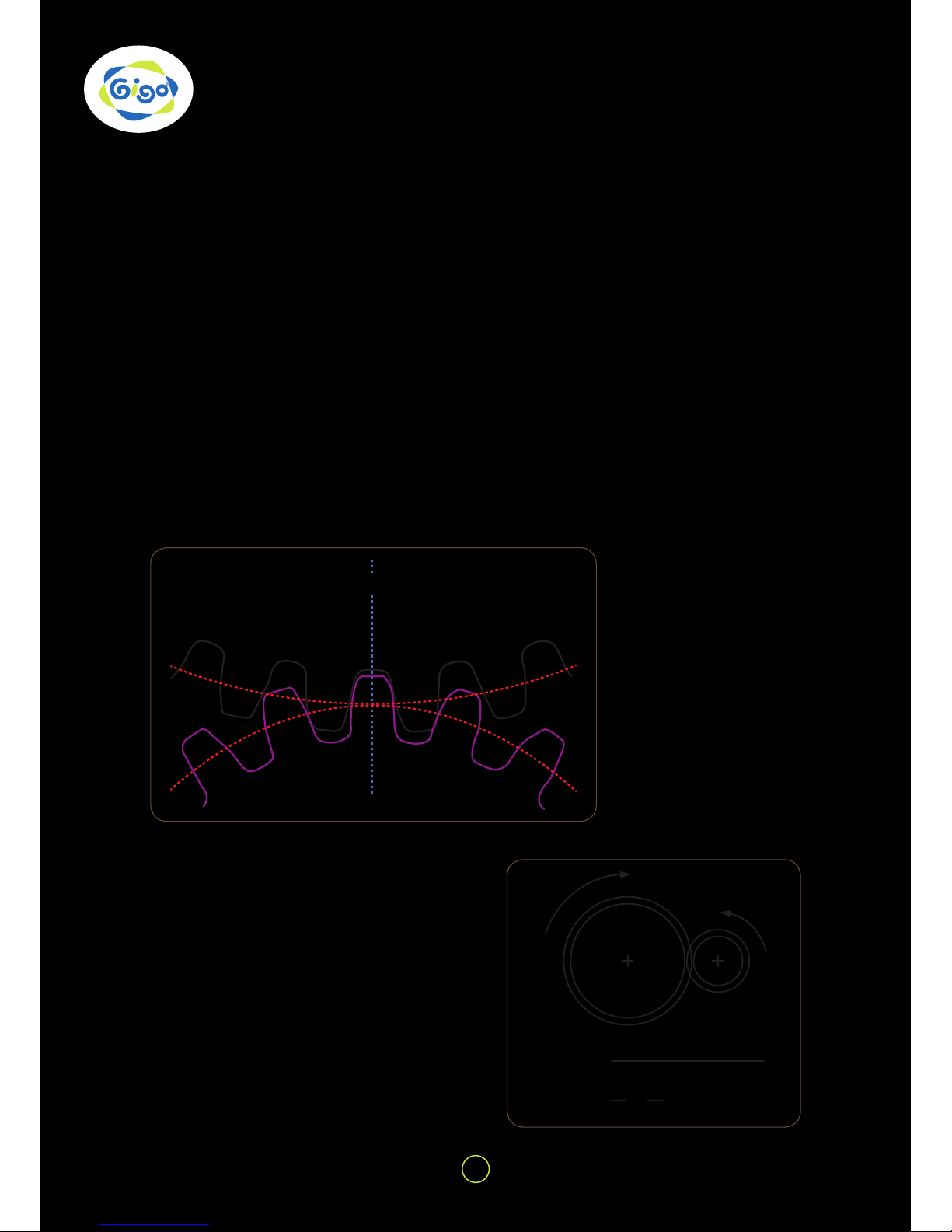

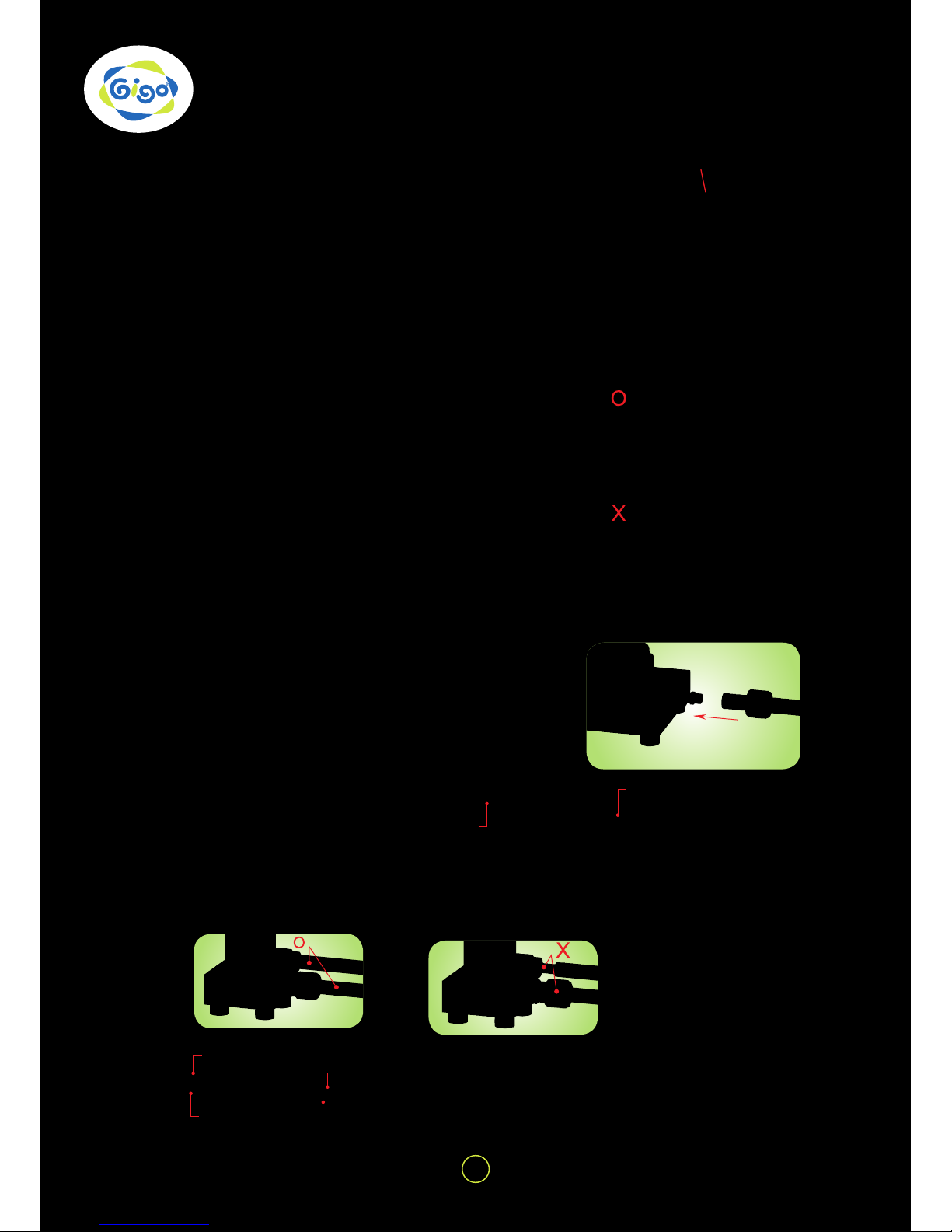

The secret of GIGO designs for gears is

to place the distance between each hole

based on 10 or the multiples. In Fig. E, the

distance between the centers of the two

gears is

and therefore the two gears can be

smoothly assembled or transmitted. Oth-

er sizes of GIGO gears are also designed

with the same perfect concept, and their

holes and gears can be greatly meshed

and operated with each other!

Learning about Gears | WATER power

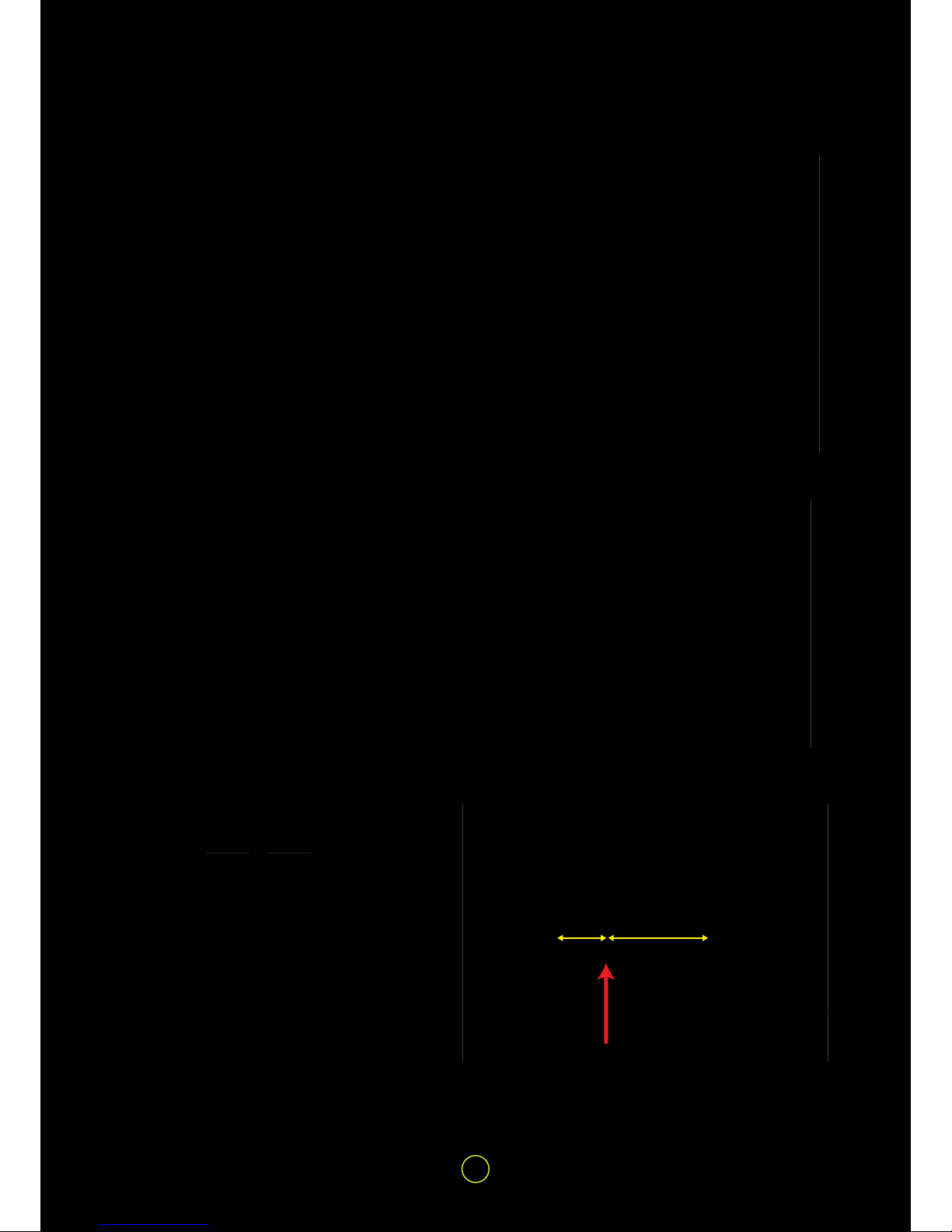

The number of teeth between the big gear

and small gear is different. Despite the

teeth number or size of the gears, the teeth

of the gears in the same gear set should

have the same size. In simple gear trains,

the driver and driven gears will rotate in

opposite directions. When a third gear

is inserted between the driver gear and

driven gear, and makes them rotate in the

same direction, it is called an idler gear.

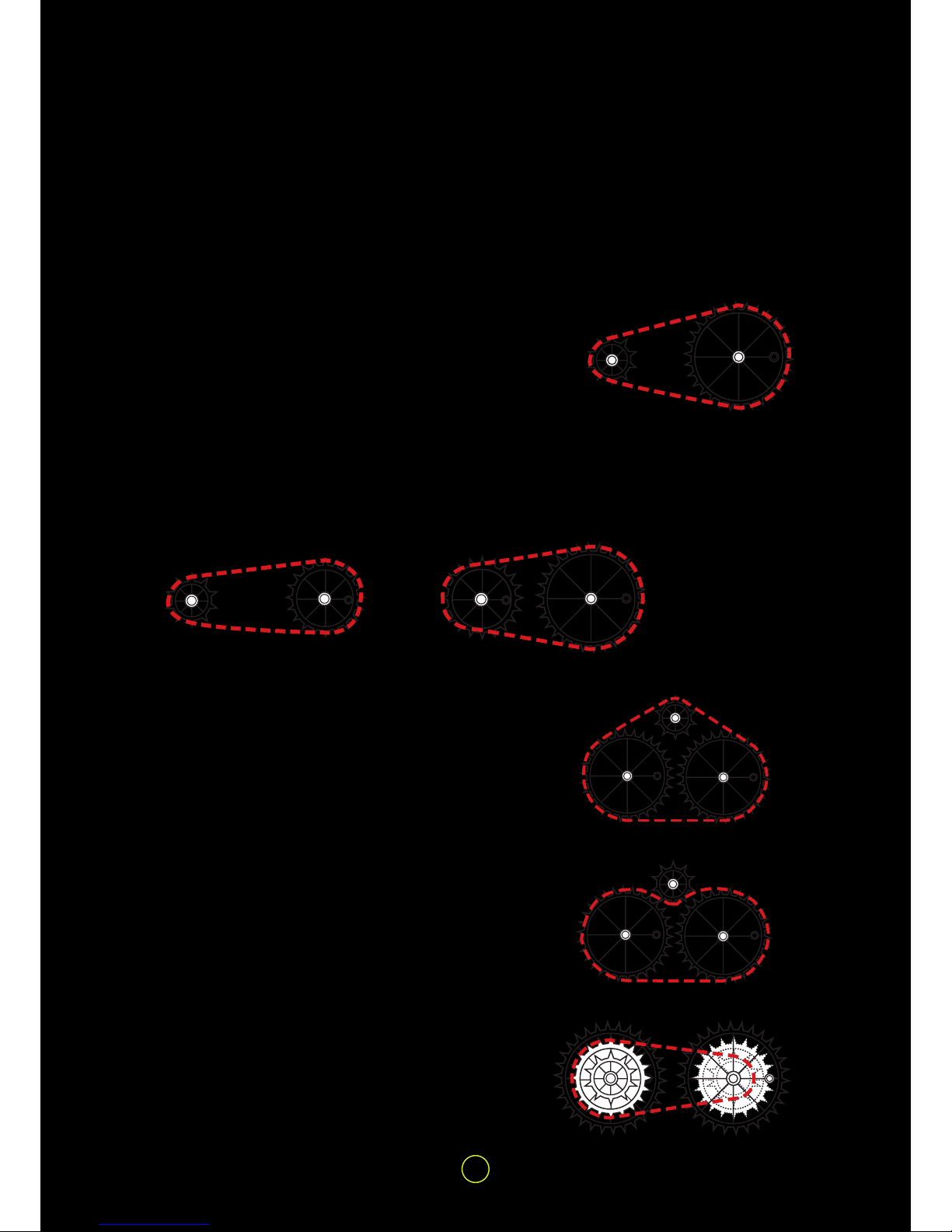

The world patent gears designed by GIGO

come in 5 different types: 20T, 40T, 60T,

80T, and 160T, the extra large gears.

Each of GIGO gear sets contains both

spur and bevel gears. Gears of HYDRO-

PNEUMATIC contain “Spur Gears” (gear

wheel to gear wheel) meshing in the same

plane and regulating speed or direction of

turning of the shafts and “Bevel Gears”

(the rounded off sections on one edge of

your gears in the set) meshed together

to change direction at right angles to the

initial turning plane of the gears and shafts

(axles).

The tooth shape of GIGO gears shares the

same speci cation of module pitches=1.

Namely, the pitch diameter of the 20T

gears is 20mm while the pitch diameter of

the 40T gears is 40mm. The pitch diame-

ters refer to the imaginary circles between

the meshed gear teeth as shown in Figure

E.

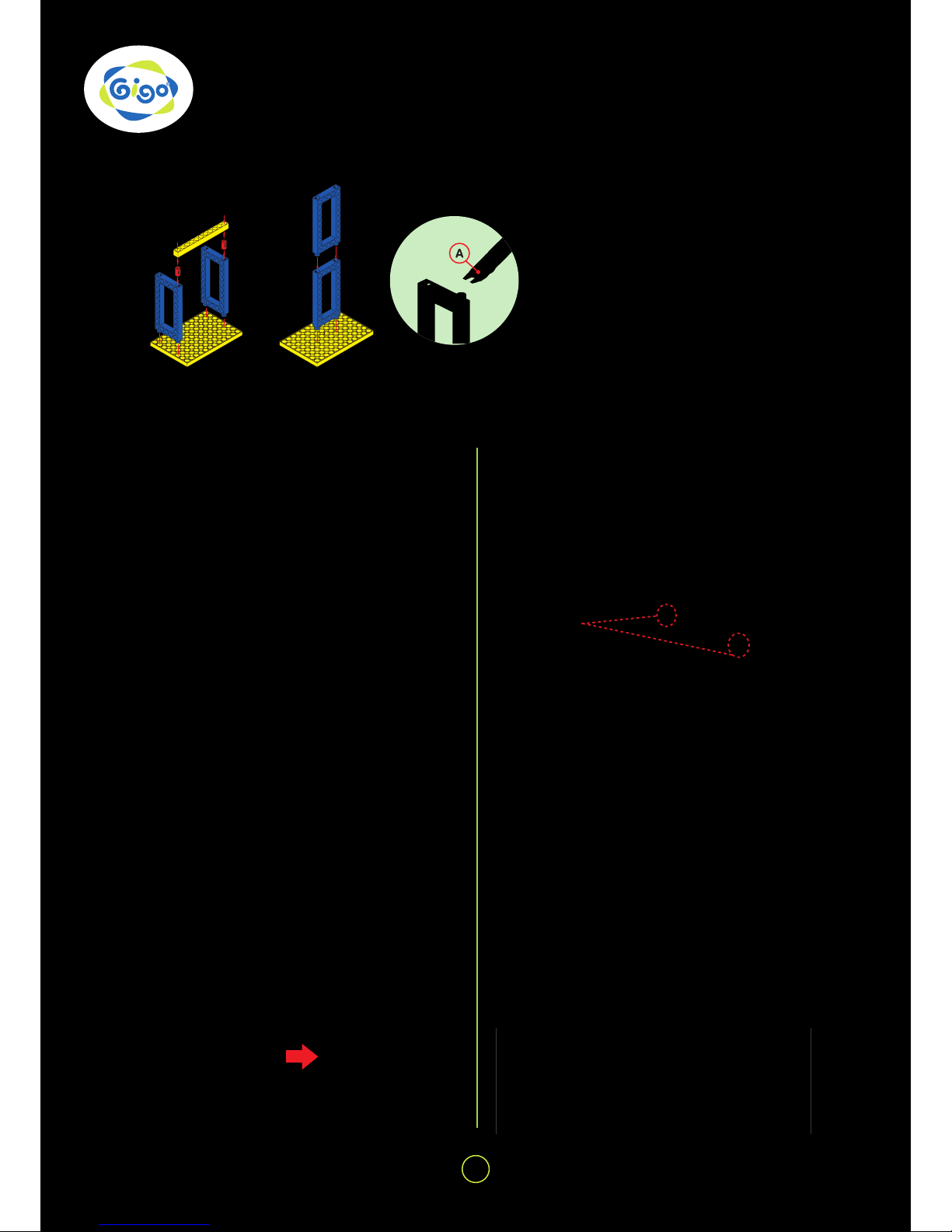

Fig. D Characteristics of GIGO gear teeth

Fig. E The transmission between the pitches

during the intermesh of two gears

Fig. C GIGO Gears

= 30mmR1+R2 = +

20mm

240mm

2

* According to the instruction above, can

you gure out how many holes there are

between a 40T and a 60T gear when they

are meshed?

R1 R2