GILDEWERK BV

GILDEWERK BV

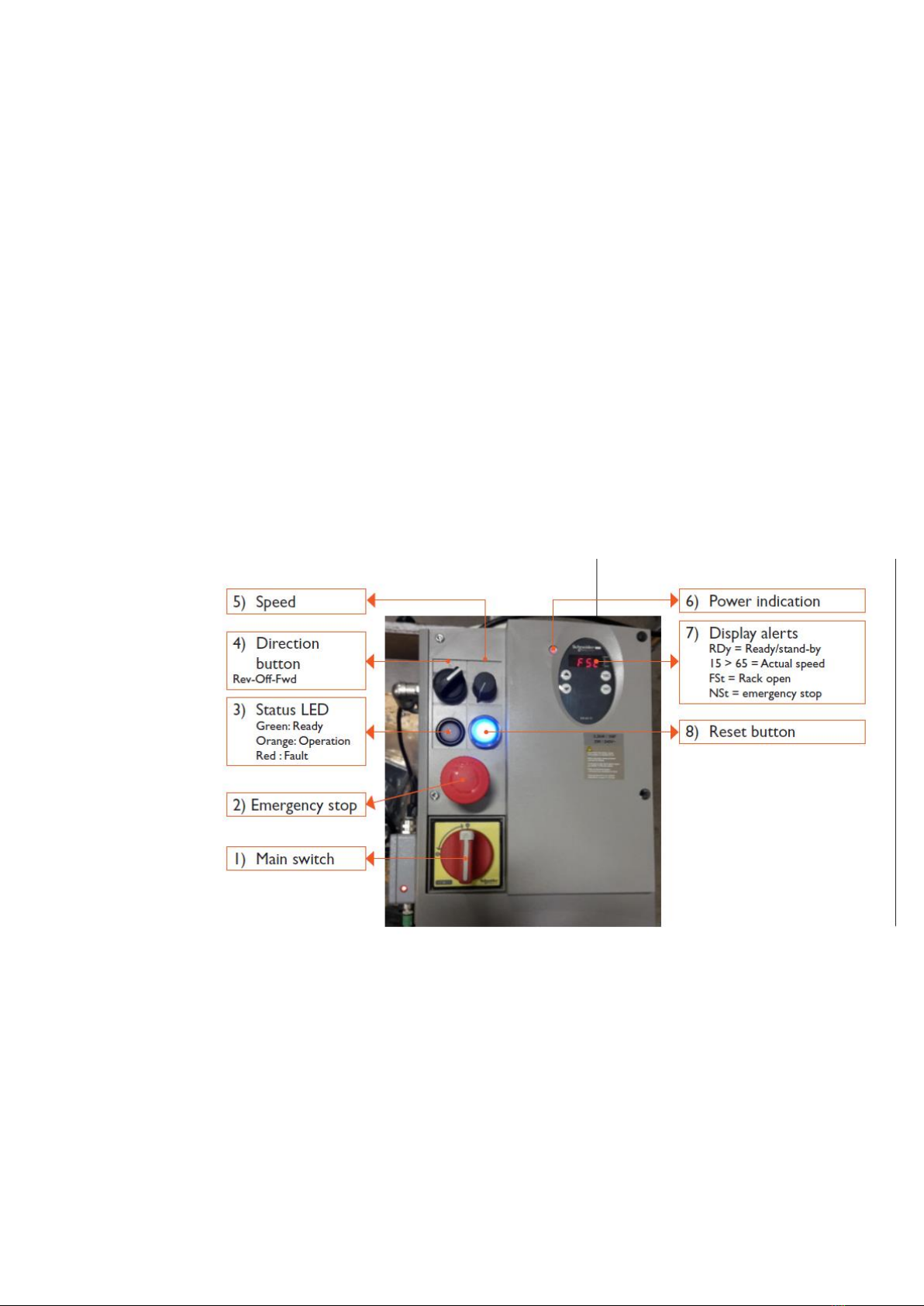

- Make sure that the main switch on the control unit is in its off position before

inserting the plug into a wall socket.

- Never connect to an unearthed wall socket!

CHAPTER 5

MAINTENANCE

1.1 CLEANING

WARNING: Place the main switch in the “0” position and remove

the plug from the wall socket before removing any

machine components!

WARNING: Never rinse or submerge any components in water,

detergents, etc. unless this is specifically prescribed!

Do the following:

-Allow the machine to empty almost completely. The machine is almost

empty when virtually no more soap exits through the extrusion plate while

the motor is running.

-Depending on the model, turn off the heating and disconnect the cord from

the press head heating cuff.

-Remove the four crosshead screws from the extrusion plate and place

these in a safe place. If one of these screws falls into the machine, it can

cause irreparable damage!

-Turn the motor back on to its slow speed and allow the pressure to push

the extrusion plate from the press head.

-Place the dial in the “R” position and briefly run the machine in reverse to

release the pressure on the worm screw.

-Use the supplied claw wrench to loosen the bronze ring on the press head

and run the machine with the dial in the “F” position, so that the press head

is forced free with the remaining soap. Make sure that it doesn’t drop off

suddenly!

-Depending on the model, disconnect the cooling system quick couplings

after shutting off the water supply.

-Use the supplied hex key to remove the three hex bolts from the press

cylinder and run the machine at its slowest speed to free the press

cylinder. The machine will stop automatically once the feeder funnel

detaches from the safety shutdown. The feeder funnel can now be

removed.

-Use the main switch to turn off the machine and remove the plug from the

wall socket.

-When removing the press head, the ‘large mixing plate’ will detach along

with it. From the front, push the remaining soap from the press head. This