3

1 INTRODUCTION

Congratulations on acquiring your new MICROMAN®

pi-

pette. MICROMAN is suitable for many dierent types of

application, including pipetting volatile, viscous, dense,

or high surface tension liquids. It is a quality product

from Gilson, which is fully ISO8655 compliant, CE labeled

(conforms to the EC directive on in vitro diagnostic

medical devices).

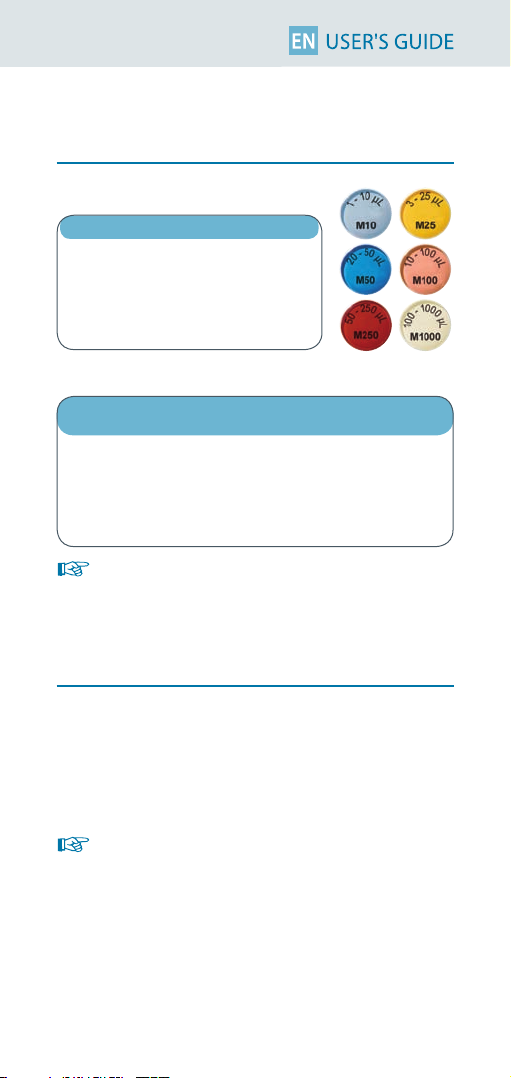

The six models permit precise and accurate pipetting

of viscous, dense and vaporous liquids. They also

allow contamination free pipetting, avoiding vapor

contamination and cross-contamination. M25, M50 and

M250, with thin and long CPs are especially suited for use

with long or narrow vessels. M10 and M100 autoclavable

models are especially suited for 100 % contamination

free pipetting.

Enjoy the following features:

- MICROMAN pipettes are equipped with a positive

displacement mechanism that isolates the aspirated

liquid from the body of the pipette. The positive dis-

placement mechanism prevents the sample-to-sample

contamination that can result from the aerosol eect.

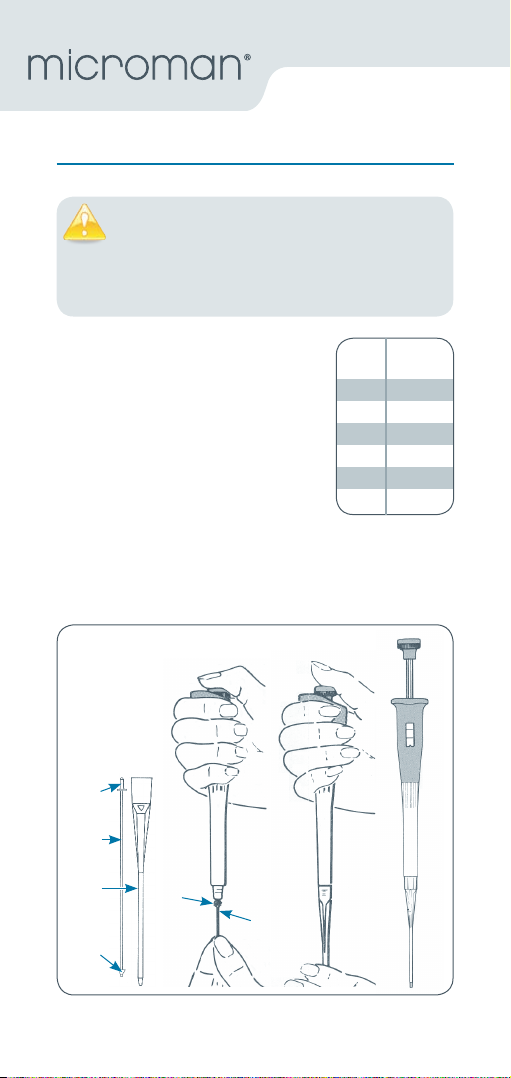

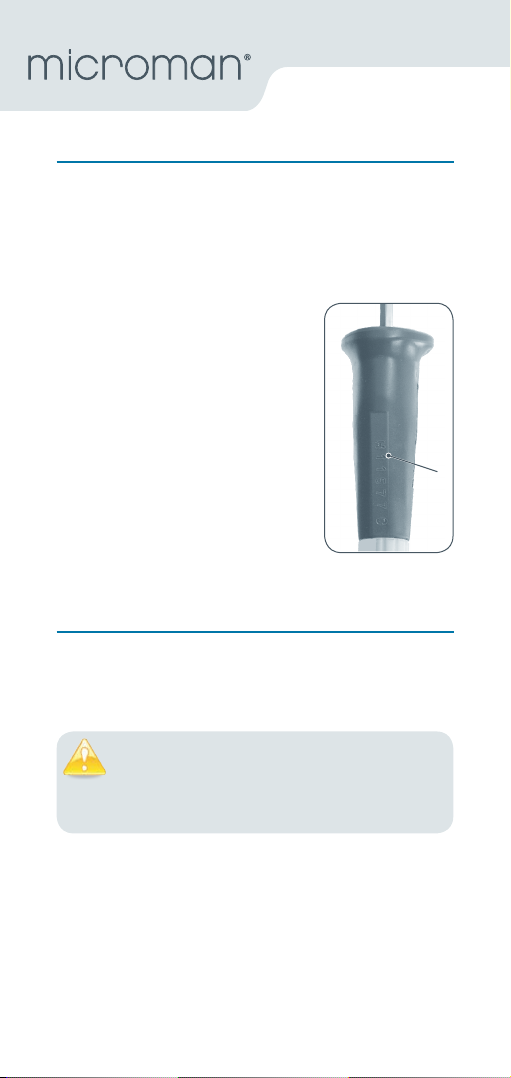

- MICROMAN uses disposable capillaries and pistons.

Changing these parts, which must be the only ones

to make contact with the aspirated liquids, can pro-

vide absolute protection against the contamination

caused by carry-over from one sample or reagent to

another. You simply have to change the capillary and

piston between each assay; they are automatically and

simultaneously ejected, thus avoiding any risk to the

operator.

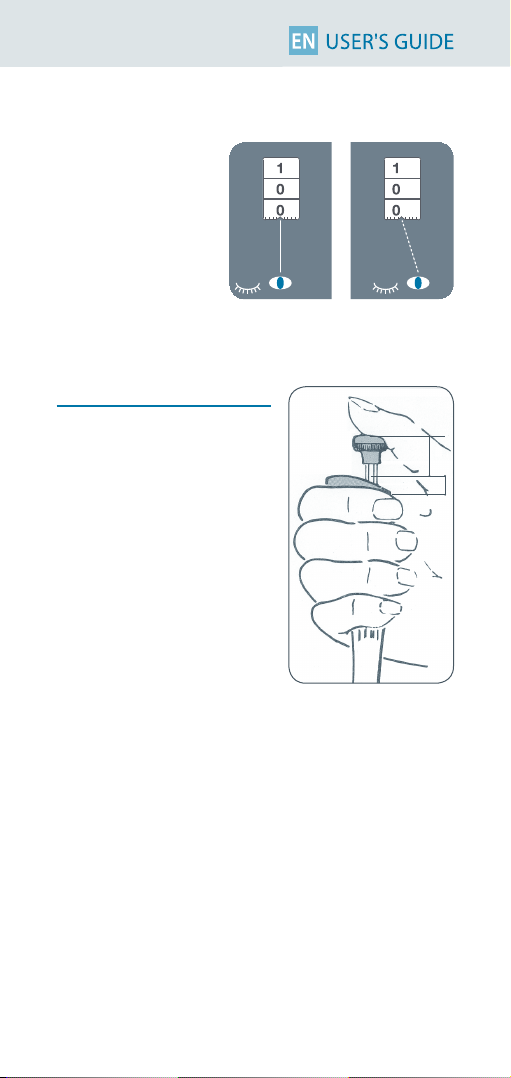

- MICROMAN is equipped with a direct reading volu-

meter that allows precise and continuous adjustment

of the required volume. MICROMAN is permanently

calibrated at the manufacturing stage, the capillary

and piston are positioned automatically, therefore it

requires no further calibration.