Impulse sealer GIMA D 351

7

VII. MAINTENANCE

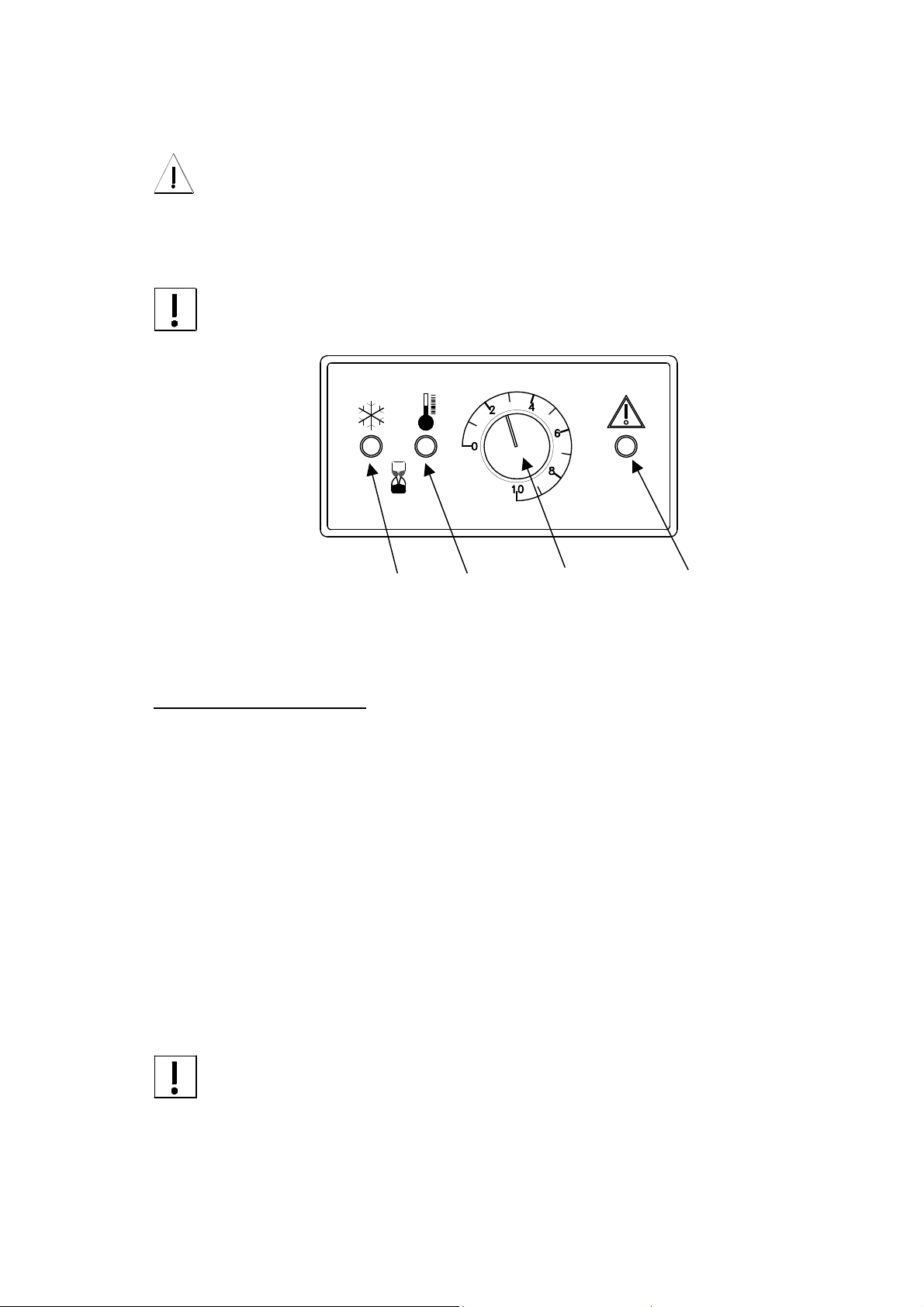

IT CAN BE EFFECTUATED ONLY BY TRAINED TECHNICIANS

ALWAYS

UNPLUG THE POWER SUPPLY CABLE (n° 1 pict. 1)

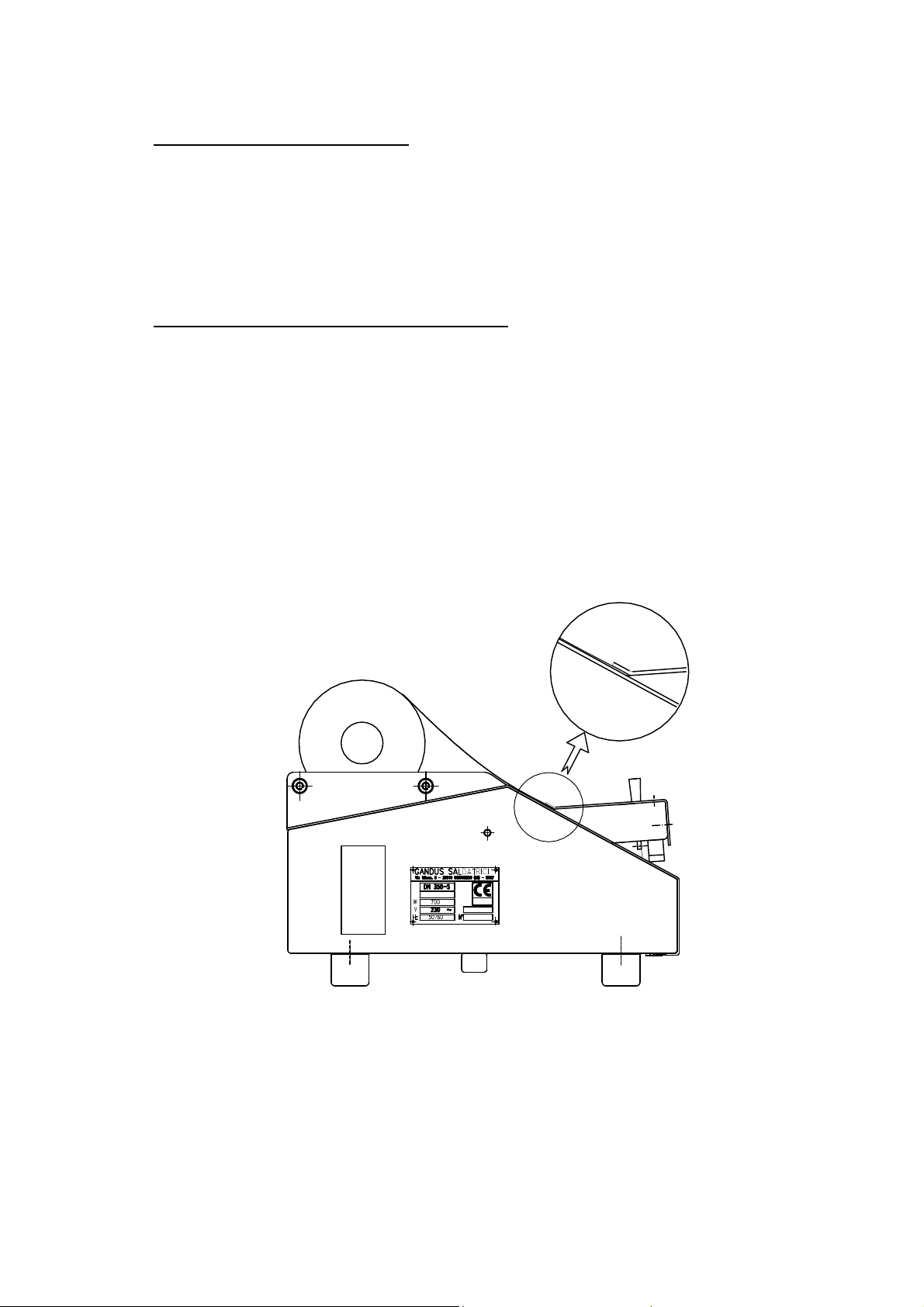

1) machine opening procedure :

To access top the inner components it is needed to remove the cover (n° pict. 2) of the machine.

Do as follows :

a) extract the cutter knob (n° 4 pict. 2) in vertical direction

b) unscrew the two rear screws (n° 4 pict. 1) and the two lower screws (n° 2 pict. 3)

c) Remove the cover (n° 3 pict. 2) of the pivoted plain , after to have unscrewed its fixing

screws (n° 5 pict. 2)

PAY ATTENTION TO THE CUTTER BLADE (n° 4 pict. 3)

d) unthread in front , the cover from the machine

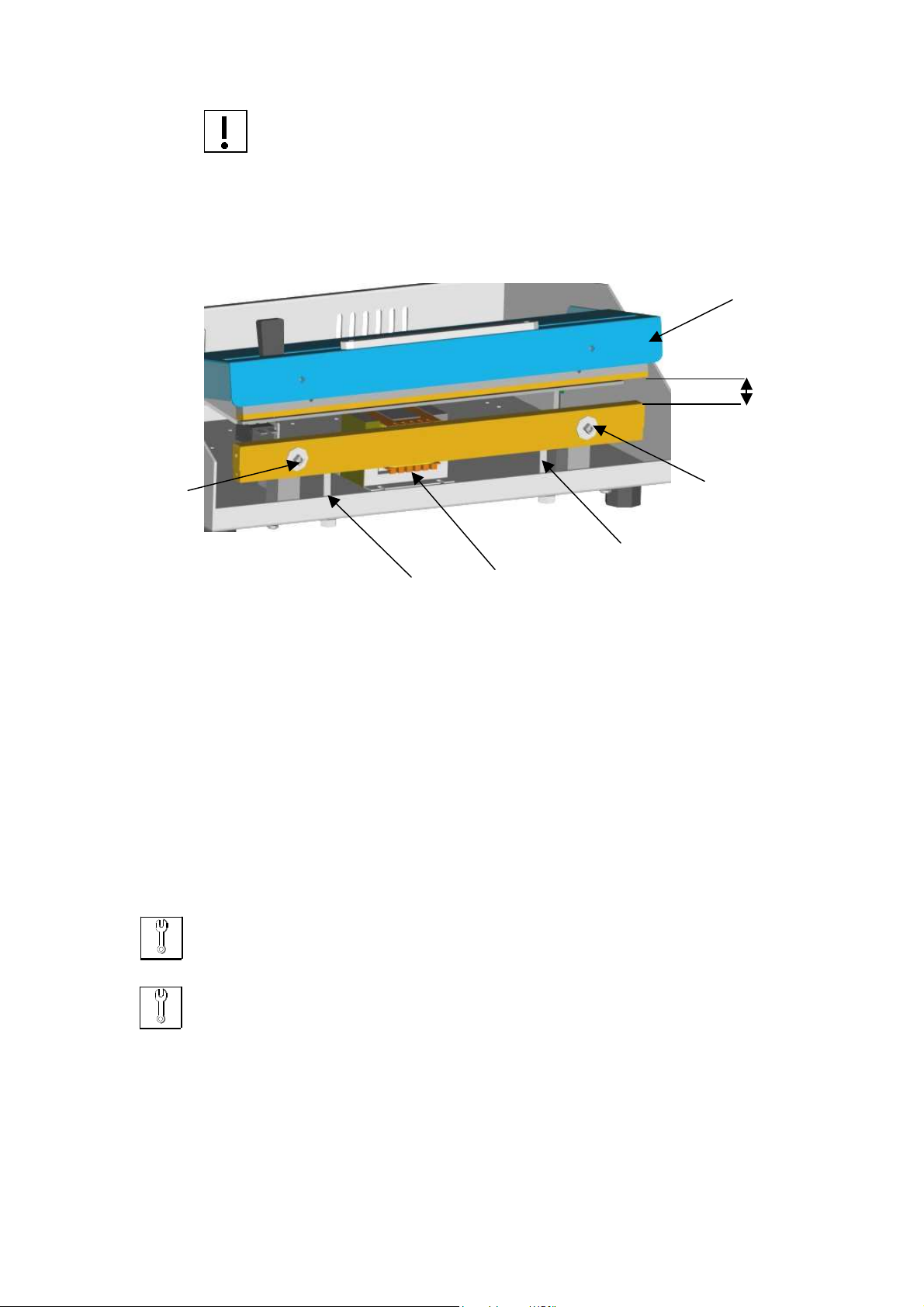

2) glass-PTFE protective cloth (n. 24 pict. 7)

The protective cloth could be damaged for normal use , for too long sealing time, or for the casual introduction

of any tools between the bars.

For the replacement proceed as follows:

a) set the pivoted plain (n°3 pict. 6) on the max opening using the adjustment opening bars ball

grip (n°1 pict. 3) located underneath the base of the machine, loosen its locknut.

b) unscrew and remove the two screws (n° 1 pict. 6)

c) extract the lower sealing bar (n° 8 pict. 2) from the machine

To work more softly , unplug the two power supply cable (n° 30 pict. 7) from the tails of the bar.

d) replace the old cloth with a new one. The original spare clothes have adhesive bands to facilitate the

application

It is very important that the bags do not make any crumples

e) fit back the sealing bar proceeding on the contrary.

f) before tighten the two screws (n. 1 pict. 6 ), be sure that the bar perfectly leans on its own

stands (n° 2 pict. 6)