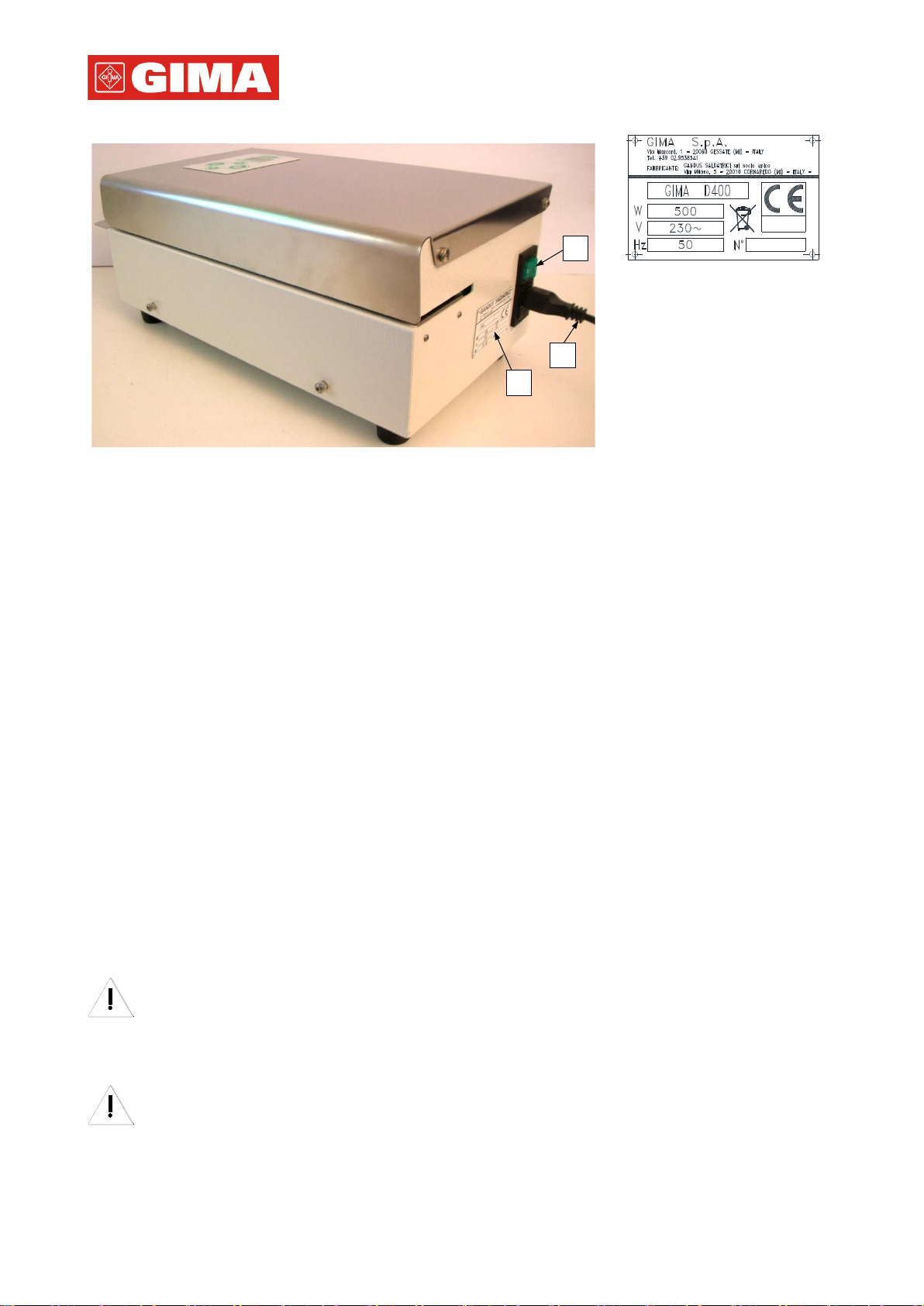

G I M A D 4 0 0

1.4 Technical characteristics

Sealing speed 6 m/min

Electronic temperature control with 10°C - 200°C ( 1%)

Automatic stop of the heat-sealer if the sealing temperature has fallen down from

setting value in a range 5°C.

Autotest function

Check internal temperature machine using thermal probe

LC display with 2 lines for 8 characters

Membrane keyboard with keys with buzzer

Sealing width 12,5 mm multilines

Free edge over the seal 0 - 30 mm

Preadjusted sealing pressure

Power supply: 230-240V 50/60Hz or 100-115V 50/60Hz

Power absorption 500 W

Acoustic emission level 70 dB(A)

Dimensions without accessories:

Width = 473 mm - Depth = 235 mm - Height = 181 mm

Net weight12,5 Kg

As for DIN 58953 P. 7 specifications

Built in accordance to the CE rules

Environmental working conditions: Temperature: from 5°C to 40°C (from 41°F to 104°F)

Humidity relative: 30% - 95% (without condensation)

GANDUS SALDATRICI S.r.l. socio unico reserves the right to modify the machines

they construct without any obligation respect to those previously supplied

1.5 Transport and moving

We suggest to use the original packing during the transport.

We suggest to handle with care and to keep the packing, in dry environment,

following the positioning symbols.

TO AVOID DAMAGE TO THE MACHINE, WHEN IT IS MOVED, IS

FONDAMENTAL TO PRESERVE THE ORIGINAL PACKING.

GANDUS SALDATRICI S.r.l. socio unico declines every responsibility for eventual

damages to the machine, in case of shipments made without the original packing

To avoid damage when unpacking and for subsequent movements, act only below the

basement.

The heat-sealer can be damaged if lifted or moved using other parts such as

casing, conveyors, etc.