QF-830-009 –sMart Vent™

Revision Level A

Girard Equipment, Inc. | GS09086 to GS10007 (GEN. 1)

GS07980 to GS08060 (GEN. 2)

Table of Contents

Technical Data............................................................................................3

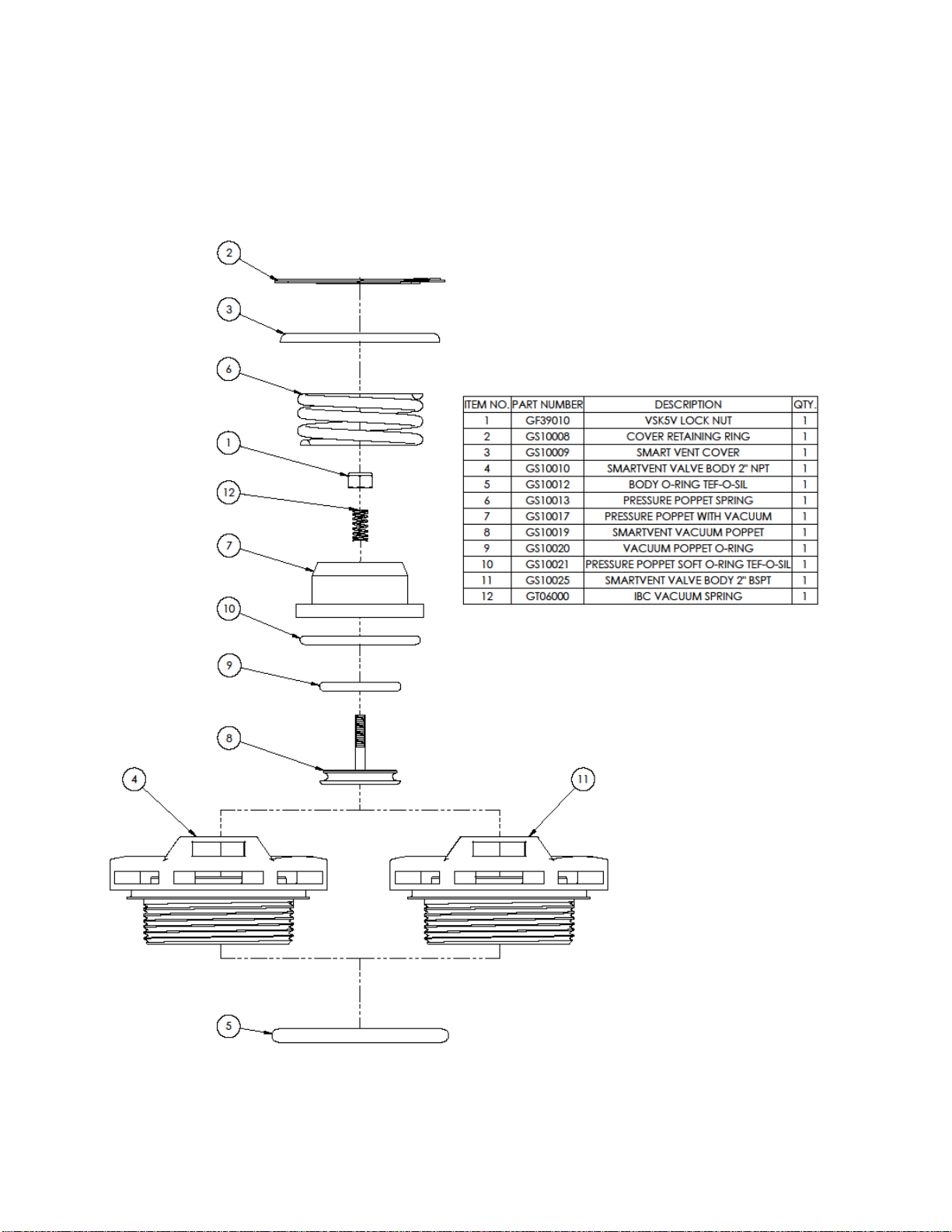

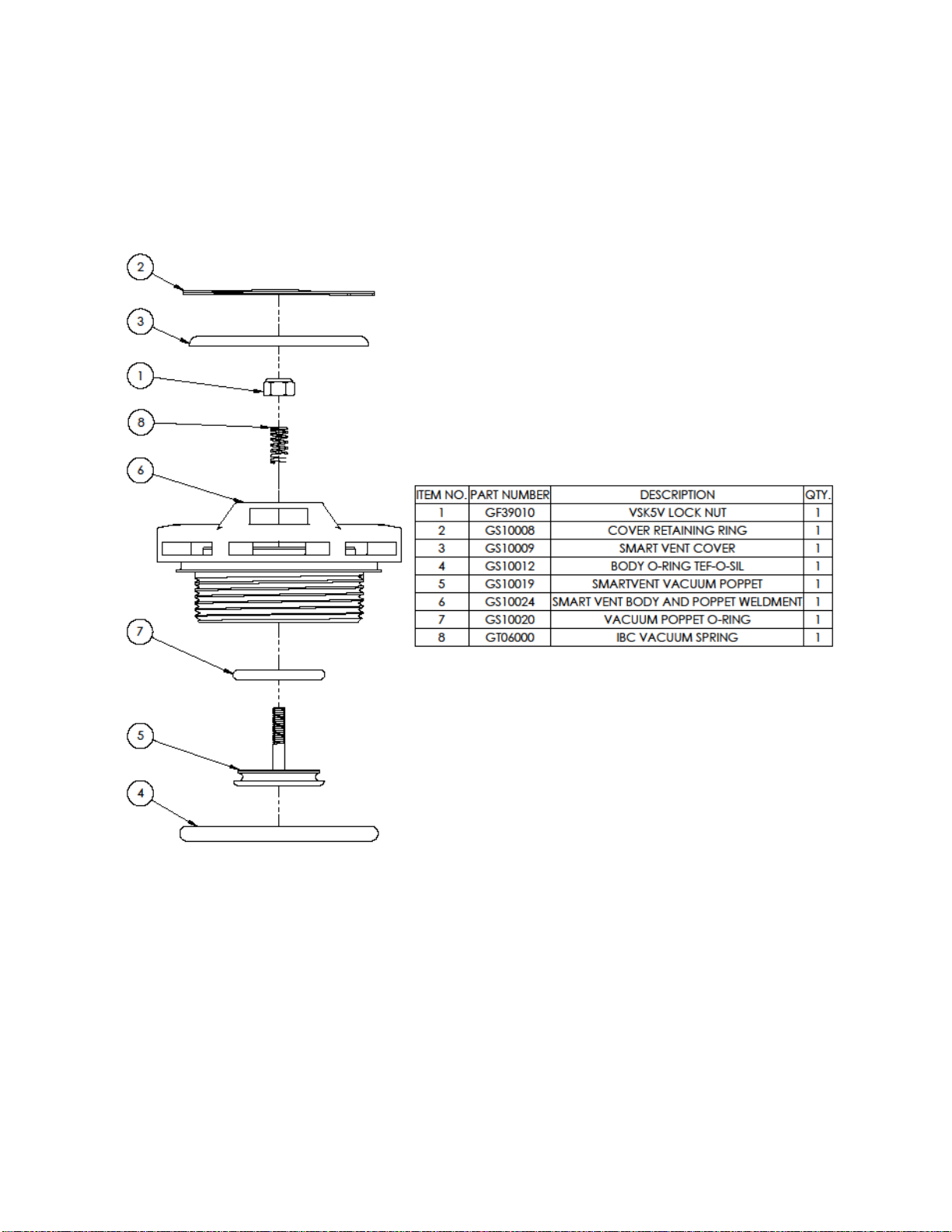

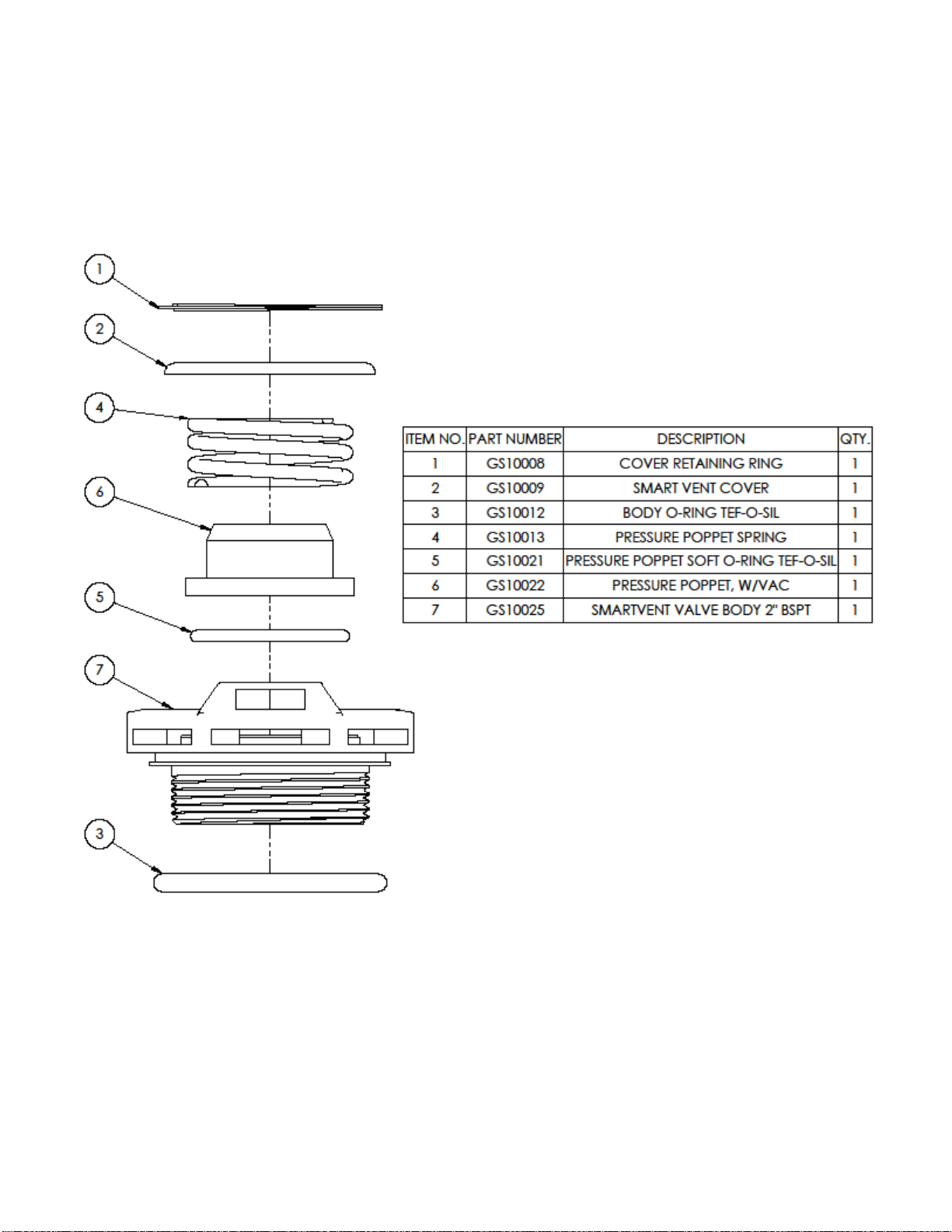

Exploded View of Product..................................................................... 4-8

Safety...........................................................................................................8

General Safety Information................................................................................9

Product Storage.................................................................................................9

Product Handling ...............................................................................................9

Disposal Requirements......................................................................................9

Installation Instructions.......................................................................... 10

Operation Instructions............................................................................ 10

Maintenance Instructions.................................................................. 10-16

Test Instructions ..................................................................................... 17

Troubleshooting & Repair ...................................................................... 17

Replacement Parts.................................................................................. 18

Warranty................................................................................................... 19

Contact Information................................................................................ 19