Rev 0 9/11

INTRODUCTION OF THE INHALATION EXPOSURE SYSTEM (IES):

The Inhalation Exposure System (IES) is an instrument manufactured by Glas-Col that provides

reproducible animal exposure to droplet-borne contaminates and infectious agents. It produces

deep-lung infections that more closely simulate real-world circumstances.

The system allows you to vary the concentration of airborne pathogens, the rate of airflow and

the length of exposure, so experiments can be reproduced accurately. The system is a whole-

body expose chamber for the quantitative infection of animals by inhalation of air bearing the

pathogenic agent.

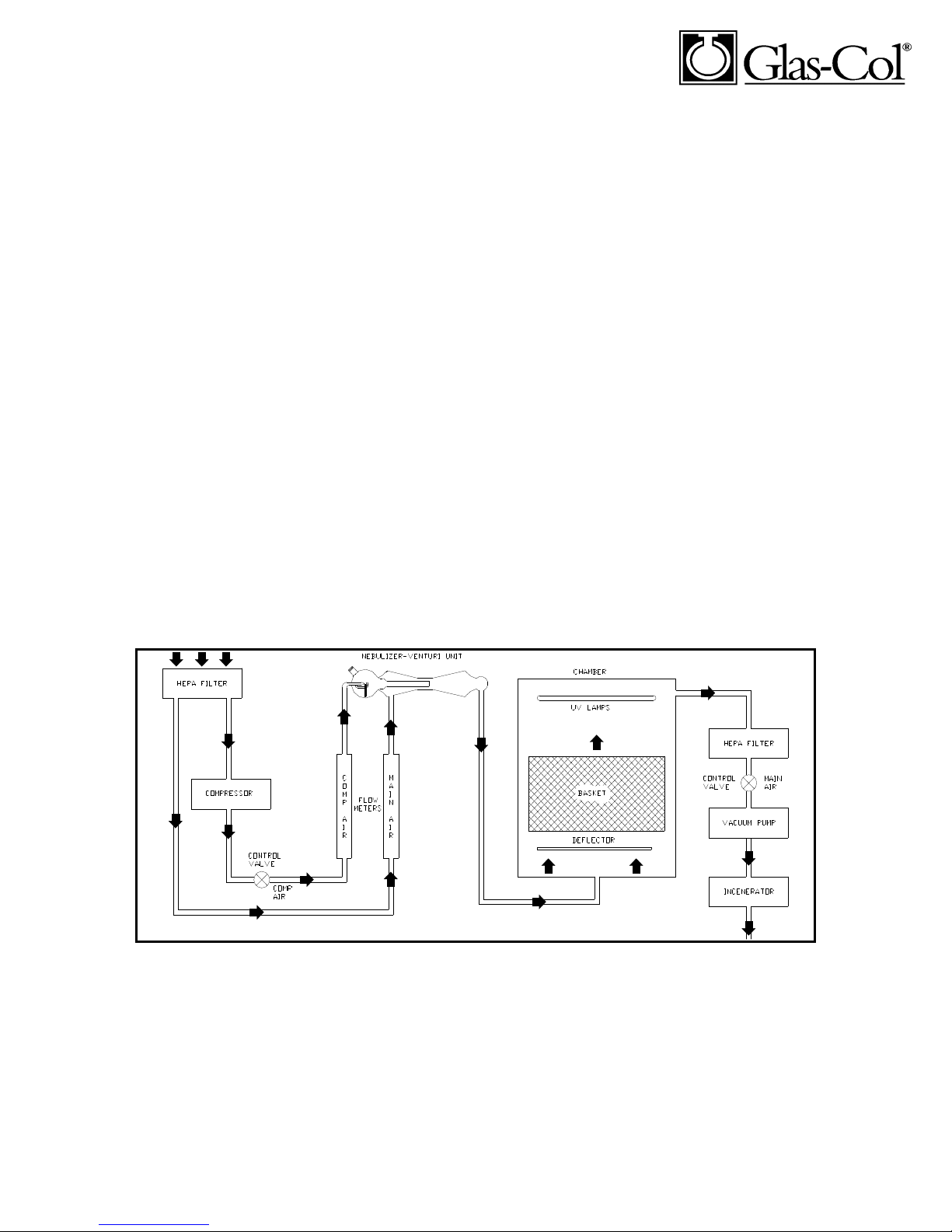

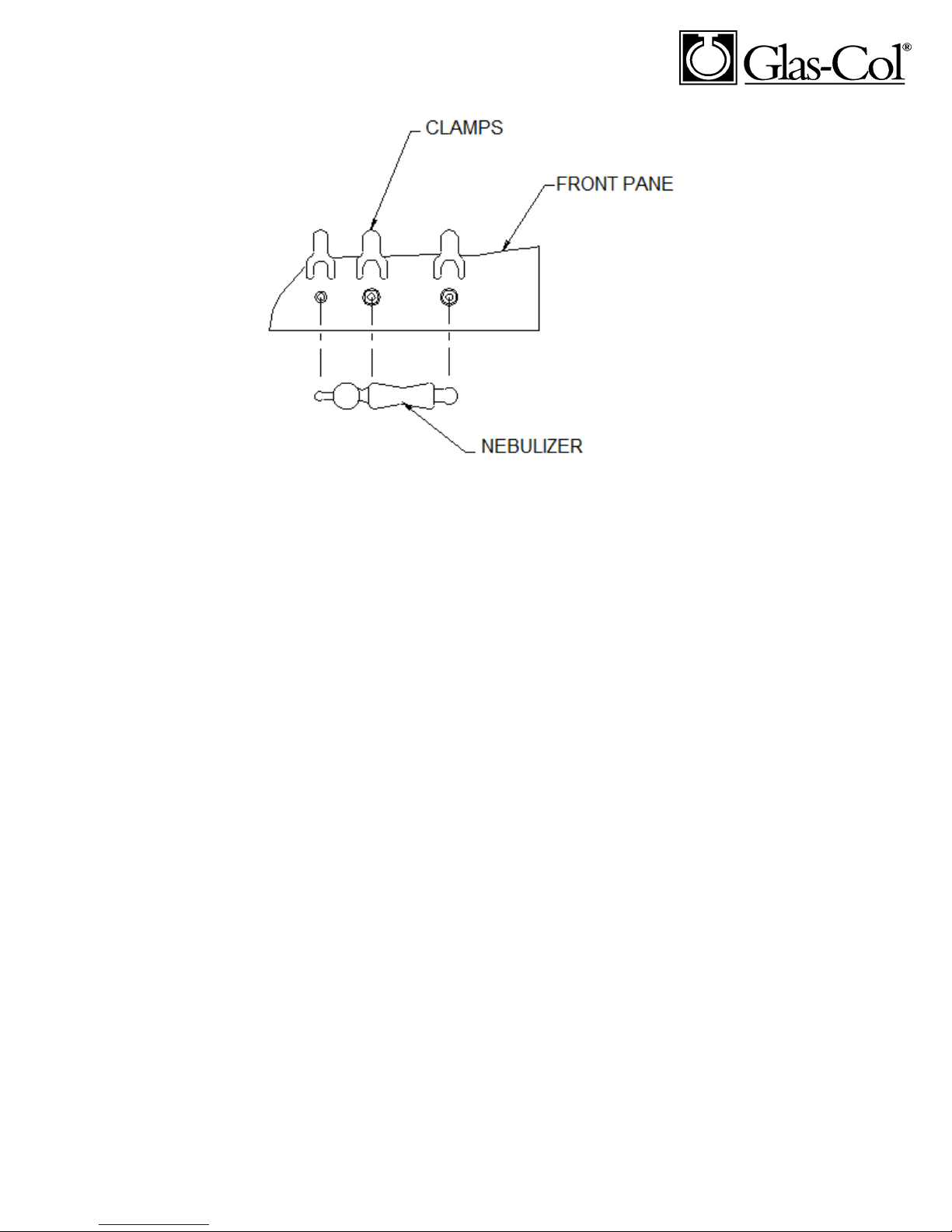

The heart of the system is the nebulizer-venturi unit into which the suspension is introduced.

Air under pressure atomizes the suspension, which is mixed with filtered room air drawn into

the system by a suction beyond the decontaminate system. By varying the number of micro-

organisms in the suspension, the proportion of bacteria-bearing nuclei can be varied. The

system permits control of the volume of air moving through the chamber per unit of time.

The animals are placed in a compartment mesh basket within the chamber. Compressed air and

vacuum pumps, along with the necessary controls and flow indicators, are built into the system.

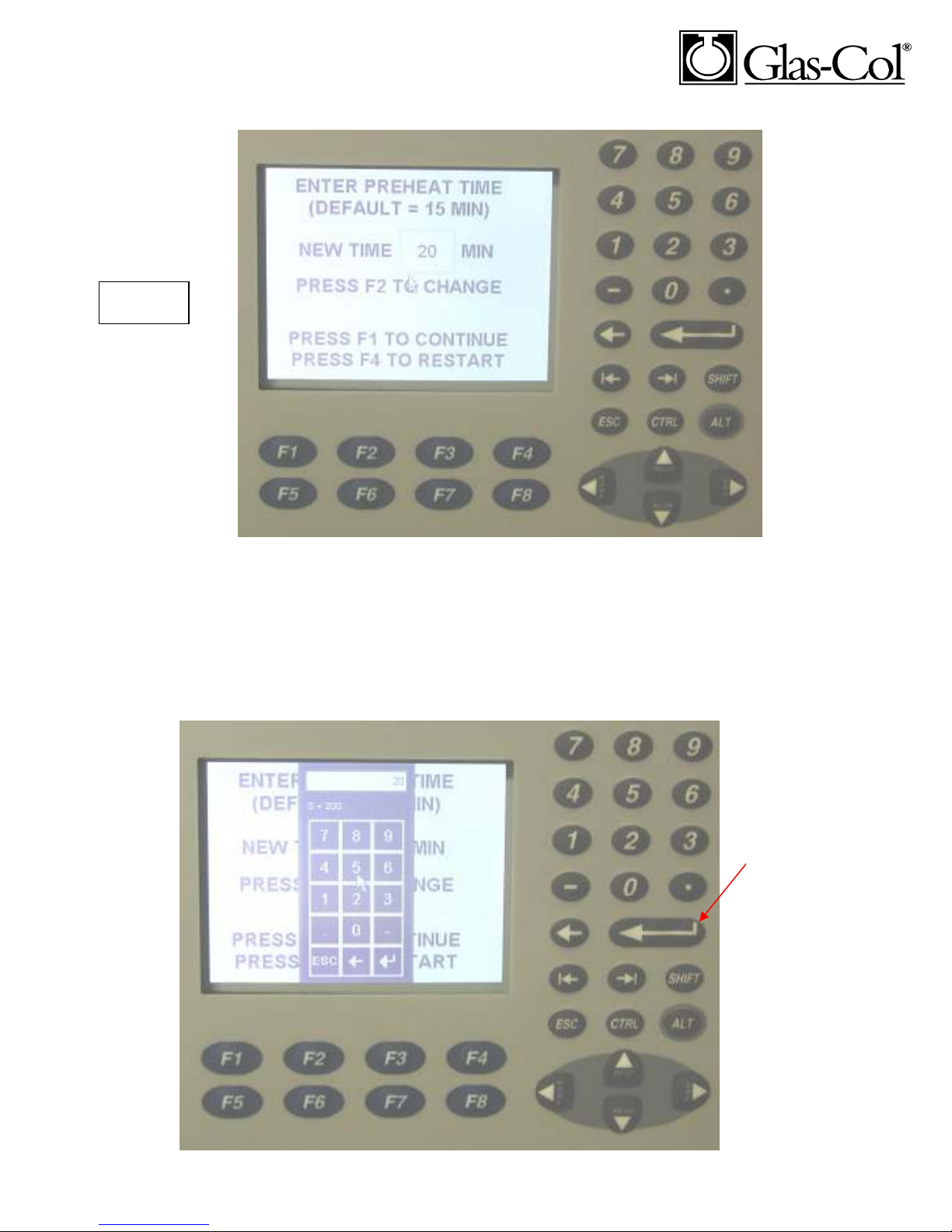

The entire unit is always operated under negative pressure (vacuum). A micro controller is

used to control the preheat, nebulizing, cloud decay, and decontamination periods. A Hepa

filter and ultraviolet lamps are provided for cleaning the system.

Below in Figure 1, is the Inhalation Exposure System diagramed in the present state.

Figure 1. Diagram of Inhalation Exposure System