INSTALLATION & OPERATION

INSTR CTIONS

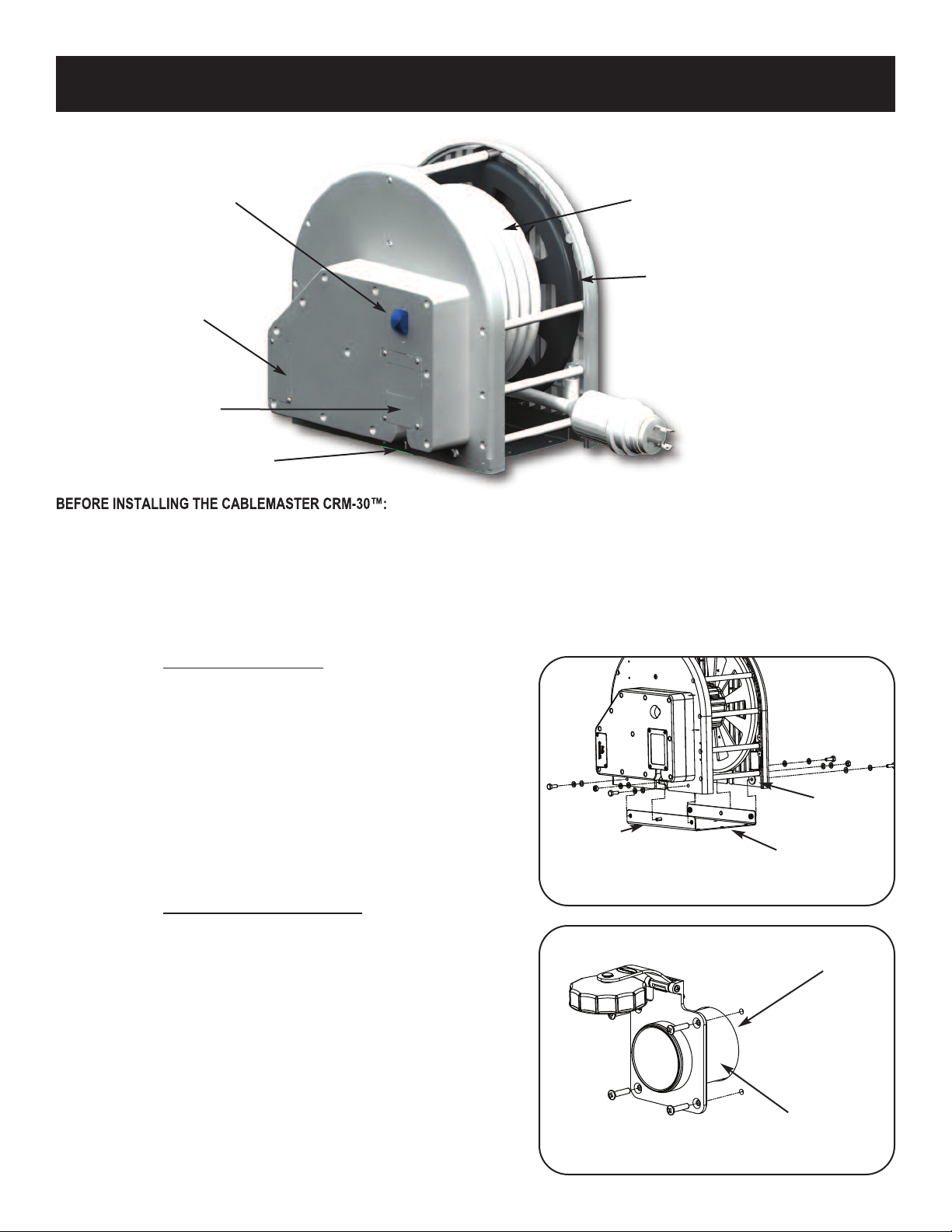

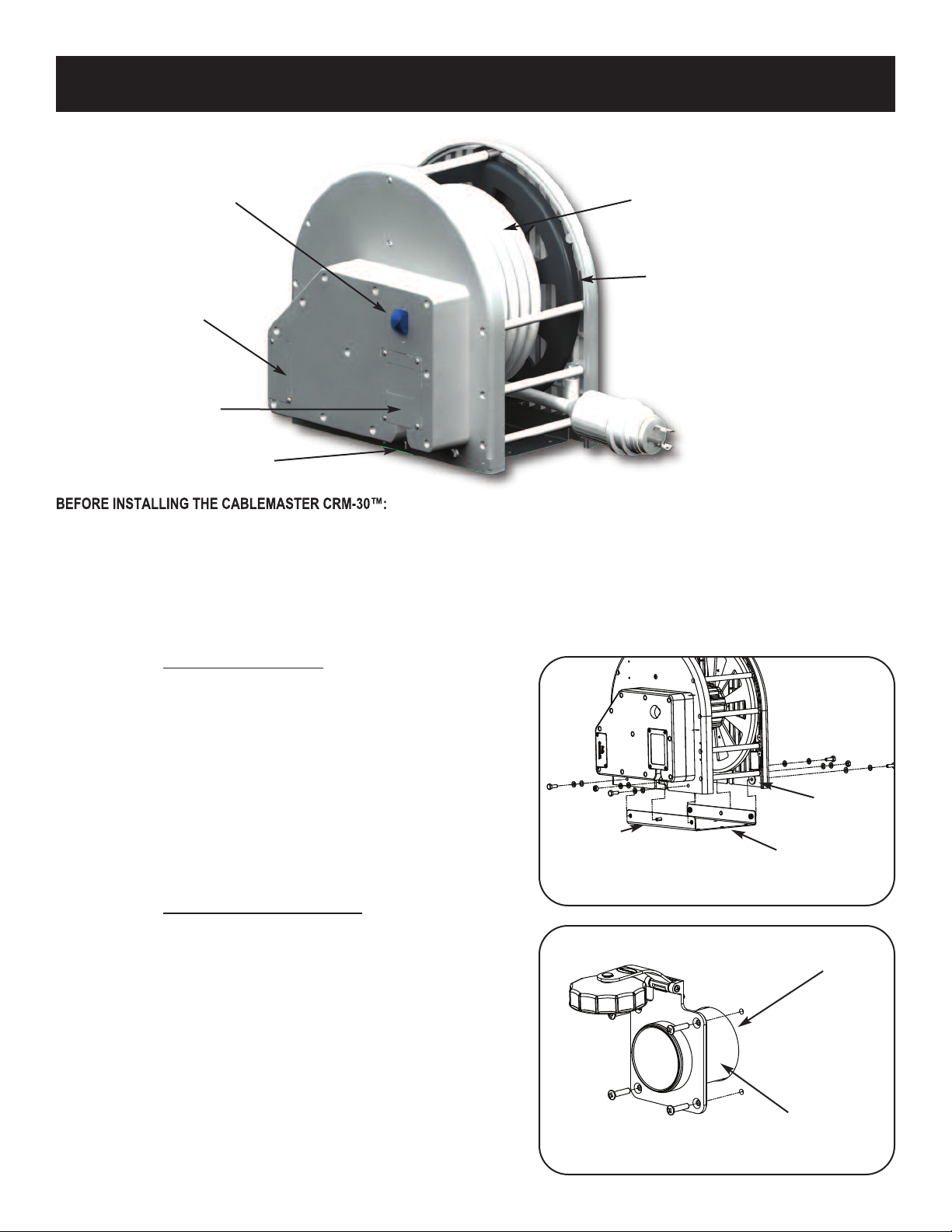

BEFORE INSTALLING THE CABLEMASTER CRM-30™:

Before installing the mounting bracket, identify the compartment where the Cablemaster™ will be installed. The Cablemaster™ MUST BE installed in

an area that is sheltered from the elements. For proper operation of the Cablemaster™ the power cord exit MUST be centered with the center of the

reel or the power cord will wrap on one side of the reel closest to the exit and could bind during retraction. If the exit is N T centered, you will need to

purchase additional accessories to aid in this installation. Measure the compartment to insure there is enough space for the Cablemaster™. Make sure

that a 3-1/2” space (minimum) is allowed for electrical connections on the circuit breaker side of the Cablemaster™.

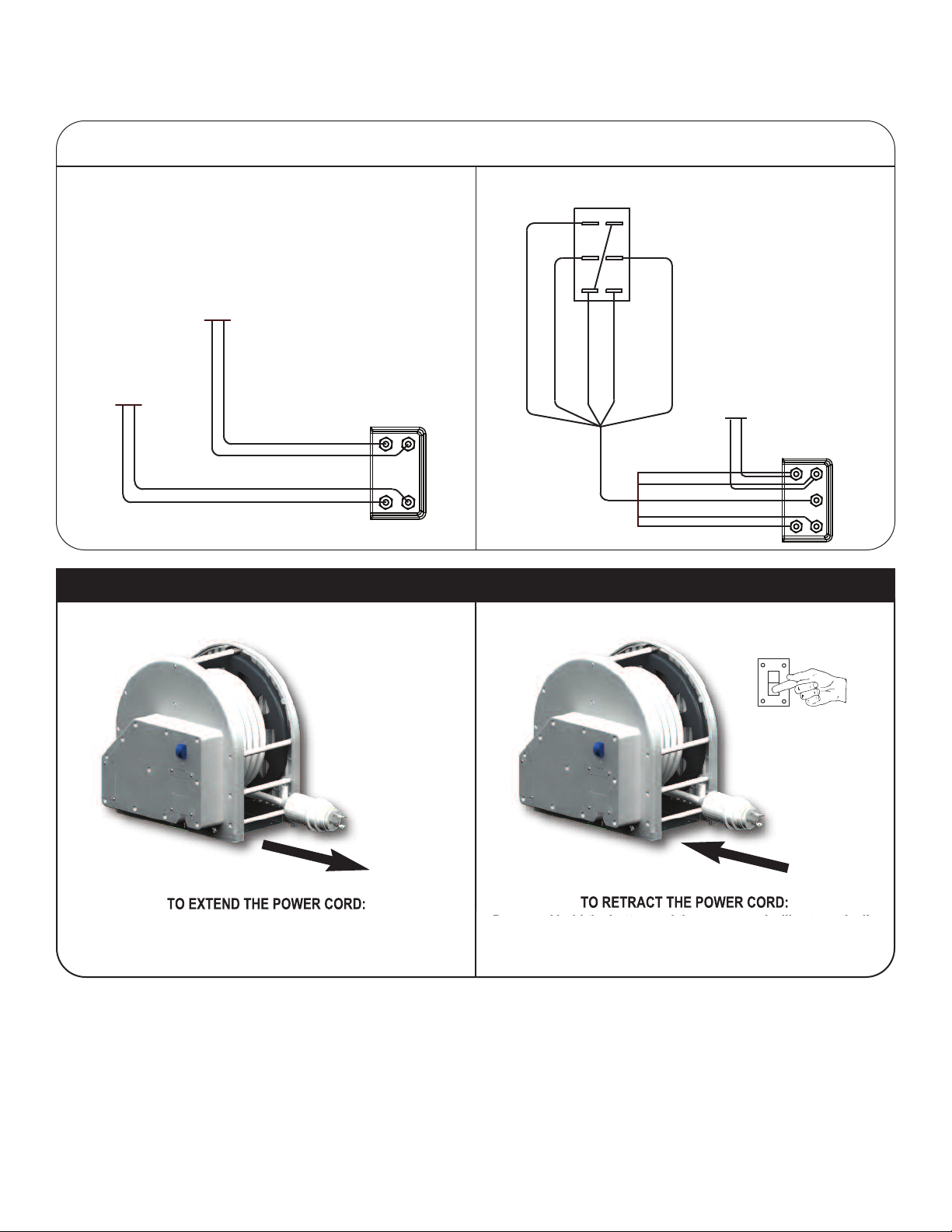

STEP 1. MOUNT CABLEMASTER™ (Fig. 1)

The Cablemaster™ comes with a mounting bracket for easy installation of the

unit. Install the mounting bracket using bolts or screws (installer supplied) fas-

tening the bracket to the floor, wall or top of the compartment.

nce the mounting bracket is secured to the compartment space you may con-

nect the Cablemaster™ to the mounting bracket. Align the lock notches on the

base of the unit with the corresponding pegs on the mounting bracket. nce the

notches have been properly aligned, slide the unit locking it into place with the

mounting bracket. Attach the Cablemaster™ to the mounting bracket using the

bolts, washers and nuts supplied.

STEP 2. INSTALL HA SE PIPE [optional] (Fig. 2)

The installation of the Hawse Pipe is optional. You may also use your existing

Hawse Pipe or any storage space door that is accessible to where you want the

power cord to exit.

If you purchased a Hawse Pipe from Glendinning, follow these instructions —

Using the template provided with the Hawse Pipe, mark the location of the Hawse

Pipe. Before drilling or cutting, check to be certain that the area behind the Hawse

Pipe is free of wires, plumbing or structural supports. Mounting surface should be

a minimum 1/2” thick. Proper thickness may be achieved by using a butt block of

marine-grade plywood behind the mounting surface.

Cut the Hawse Pipe’s center hole and drill the four (4) 1/4” mounting holes. Using

740 Century Circle • Conway, SC 29526 • P: 843-399-6146 • F: 843-399-5005

www.glendinningprods.com SML-CRM30-INSTAL

LIMITED WARRANTY

PROD CT(S) COVERED BY THIS LIMITED WARRANTY: CABLEMASTER™ - MODEL CRM-30

1. GLENDINNING MARINE PRODUCTS, INC. warrants to the original consumer purchaser that the Cablemaster™ - Model CRM30 will be free from defects in material and workmanship under normal use and service for a period of

one (1) year from the date of purchase.

2. This LIMITED WARRANTY applies t defects in material and workmanship. It does not apply to chromeplated or anodized finish or to power cable damage caused by inadequate cable storage area or installation not in accordance

with GLENDINNING MARINE PROD CTS, INC. specifications.

3. This LIMITED WARRANTY is v id if the product has been damaged by accident or unreasonable use, neglect, improper installation, or other causes not arising out of defects in material or workmanship.

4. T btain perf rmance f this LIMITED WARRANTY obligation the original purchaser should contact GLENDINNING MARINE PROD CTS, INC. for instructions concerning removal and shipping of the defective component. pon

compliance of the foregoing procedure all warranted defects will be repaired, or at GLENDINNING MARINE PROD CTS, INC. option, the complete unit replaced and returned to the consumer, shipping charges prepaid.

5. GLENDINNING MARINE PRODUCTS, INC. does not assume the costs of removal and/or installation of the product or any other incidental costs which may arise as a result of any defect in materials or workmanship.

THIS WARRANTY IS IN LIE OF ALL OTHER EXPRESS WARRANTIES. ANY WARRANTY IMPLIED BY LAW INCL DING WARRANTIES OF MERCHANTABILITY OR FITNESS, IS IN EFFECT ONLY FOR THE D RATION OF

THE EXPRESS WARRANTIES SET FORTH IN THE FIRST PARAGRAPH ABOVE. NO REPRESENTATIVE OR PERSON IS A THORIZED TO GIVE ANY OTHER WARRANTY OR TO ASS ME FOR GLENDINNING MARINE

PROD CTS, INC. ANY OTHER LIABILITY IN CONNECTION WITH THE SALE OF IT’S PROD CTS. GLENDINNING MARINE PROD CTS, INC. WILL NOT BE LIABLE FOR ANY CONSEQ ENTIAL DAMAGES RES LTING FROM

THE SE OR INSTALLATION OF IT’S PROD CTS.

P/N INSTALLATION ACCESSORIES

04043 Horizontal Pipe Extension Kit

Allows the Cablemaster™ to be mounted an extended distance from the Hawse

Pipe Assembly.

CABLEMASTER CRM-30

Circuit Breaker

(optional)

“Pigtail” (optionall)

DIMENSI NS:

11.09” [282mm] W

14.08” [358mm] H

13.75” [350mm] D

Reel

DC Control Panel

AC Control Panel

105ºC rated cordset

Fig. 1

Install mounting bracket & mount unit

Use bolts or screws to

mount bracket to surface

Attach unit to

mounting bracket

Align peg with notches

Fig. 2

Install Hawse Pipe (optional)

Make sure gasket is installed

between hawse pipe flange

and exterior surface

Use template to cut / drill hole

in surface