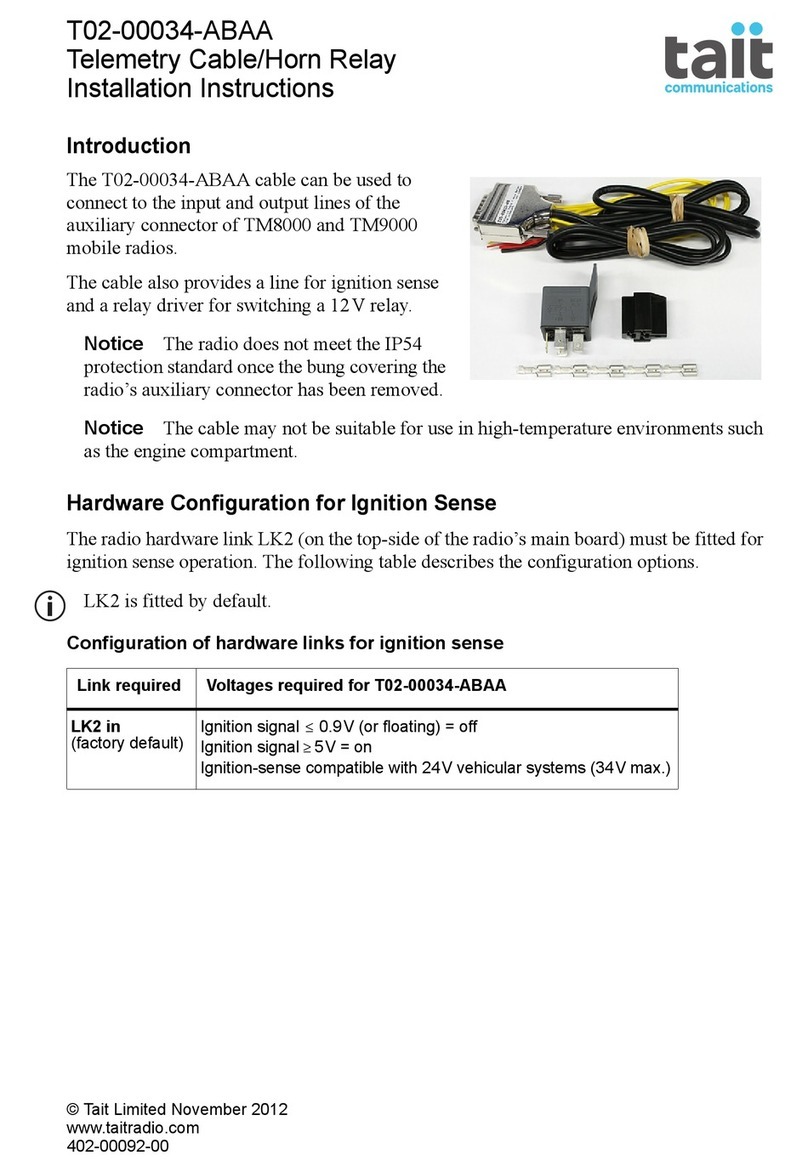

Nexans EUROMOLD K800PB/G User manual

This product should be installed only by competent personnel trained in good safety practices involving

high voltage electrical equipment. These instructions are not intended as a substitute for adequate

training or experience in such safety practices. These instructions do not attempt to provide for every

possible contingency. Failure to follow these instructions could result in damage to the product and

serious or fatal injury. IMPORTANT : Cable and associated apparatus must be de-energised, locked out,

and tagged prior to product installation.

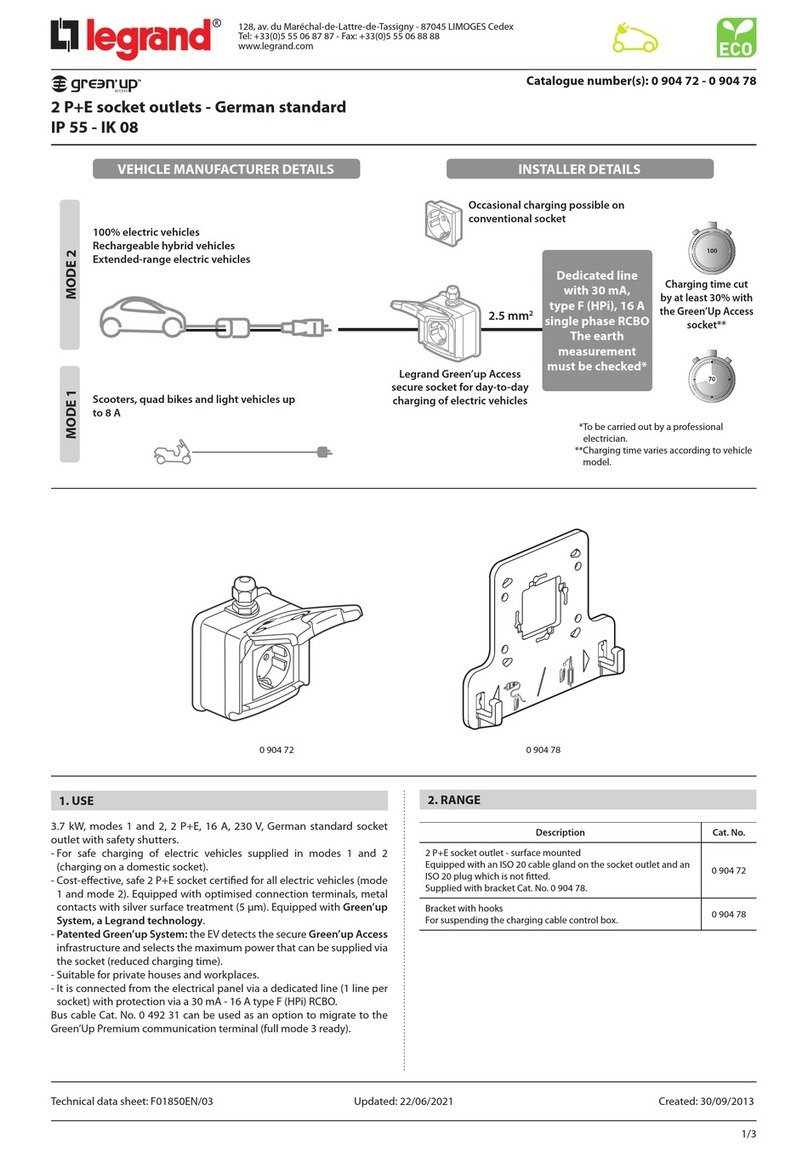

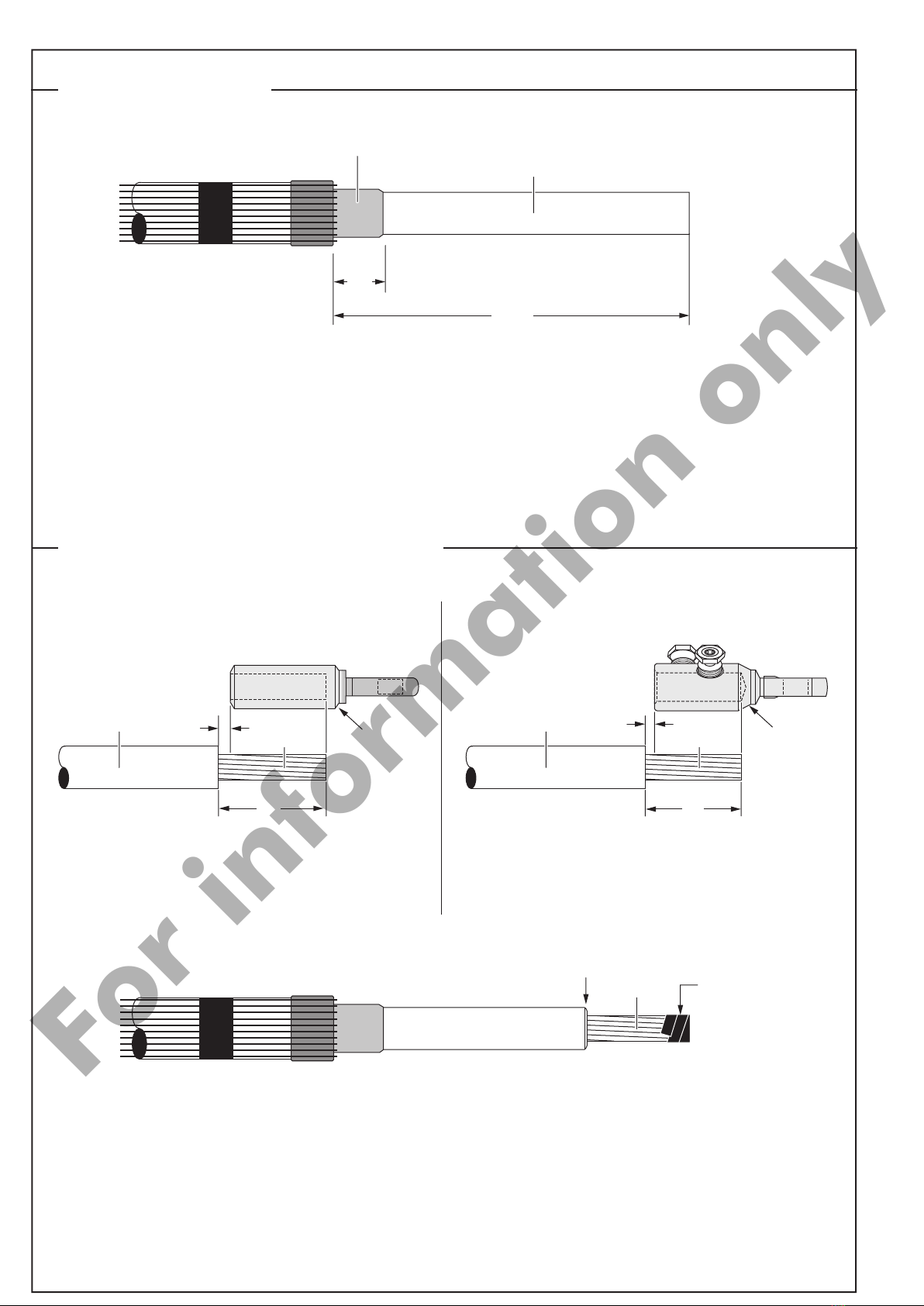

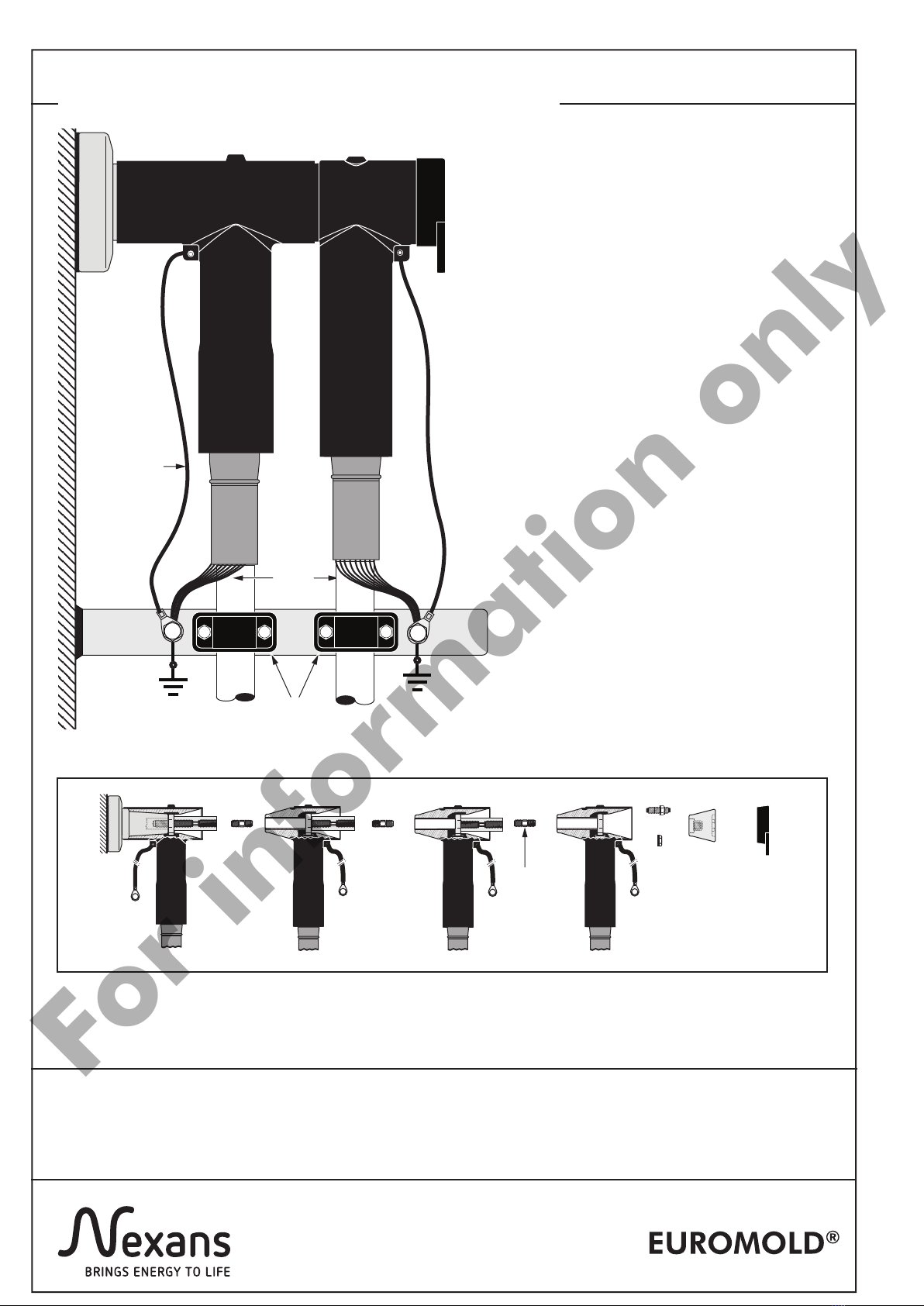

For installation on a 480TB, 484TB or 489TB tee connector or a 800PB, 804PB

or 809PB coupling connector tightened with a clamping screw (type 1)

OR

clamping

screw

clamping

screw

OR tightened with a stud and flange nut (type 2)

OR

CAUTION : Read instructions thoroughly and completely prior to beginning installation.

Installation instructions for separable coupling connector

K800PB/G

Up to 24 kV

Only to be used on copper wire screened cable with extruded semi-conductive screen

and conductors of copper or aluminium.

For installation on a 480TB, 484TB or 489TB tee connector or a

800PB, 804PB or 809PB coupling connector.

M16

flange nut

M16

flange nut

WARNING :

CHANGED INSTALLATION

Page 1 of 14

IS97180-ENG - K800PB/G-CW45-CA0

18 November 2019 - Revision 2 - Supersedes edition of 28 September 2018

IS97180-ENG - K800PB/G-CW45-CA0 - Revision 2

For information only

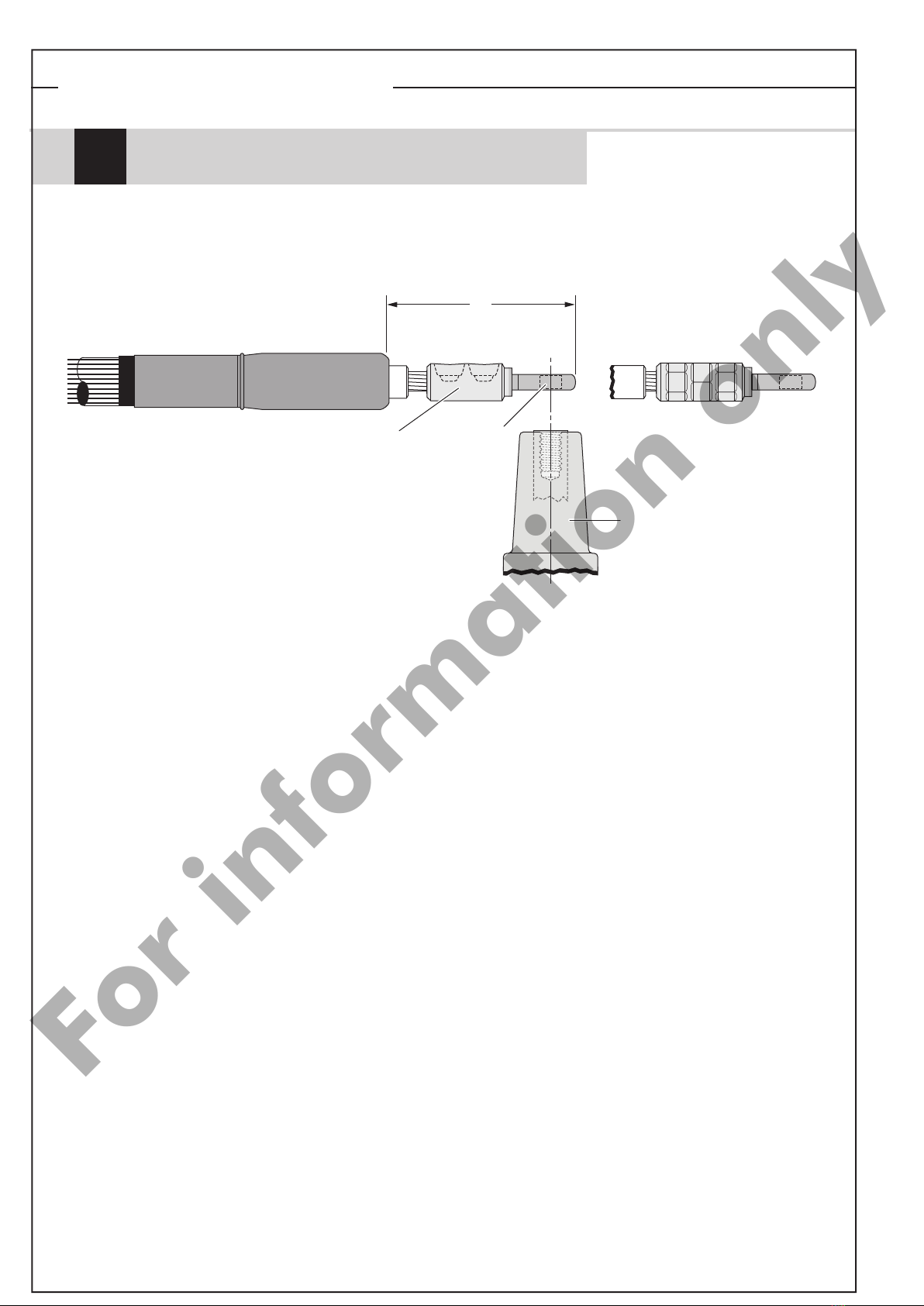

1 x Installation rod

(for conductor sizes

185 up to 300 mm²)

Required components for the connector installation :

Installation

instructions

Water sealing

mastic, type MWS

(optional)

Roll adhesive

tape Silicone grease

+ wipers

+

Gloves

3 x Coupling

connector housing

800BP

3 x Contact rod

and stud

Nylon vent rod

3 x Cable reducer

CA0-W

Check if the diameter over cable core insulation is in accordance with

the cable reducer range as indicated in table below:

Cable reducer size

(see label on cable reducer)

CA0-11

CA0-15

CA0-18

CA0-21

CA0-27

12.0

16.0

19.0

22.0

28.5

19.0

26.5

32.6

34.6

37.5

Dia. over core insulation (mm)

min max

3 x Conductor

contact - TBC-X

or TMBC-X

or

IS97180-ENG - K800PB/G-CW45-CA0 - Revision 2

Page 2 of 14

For information only

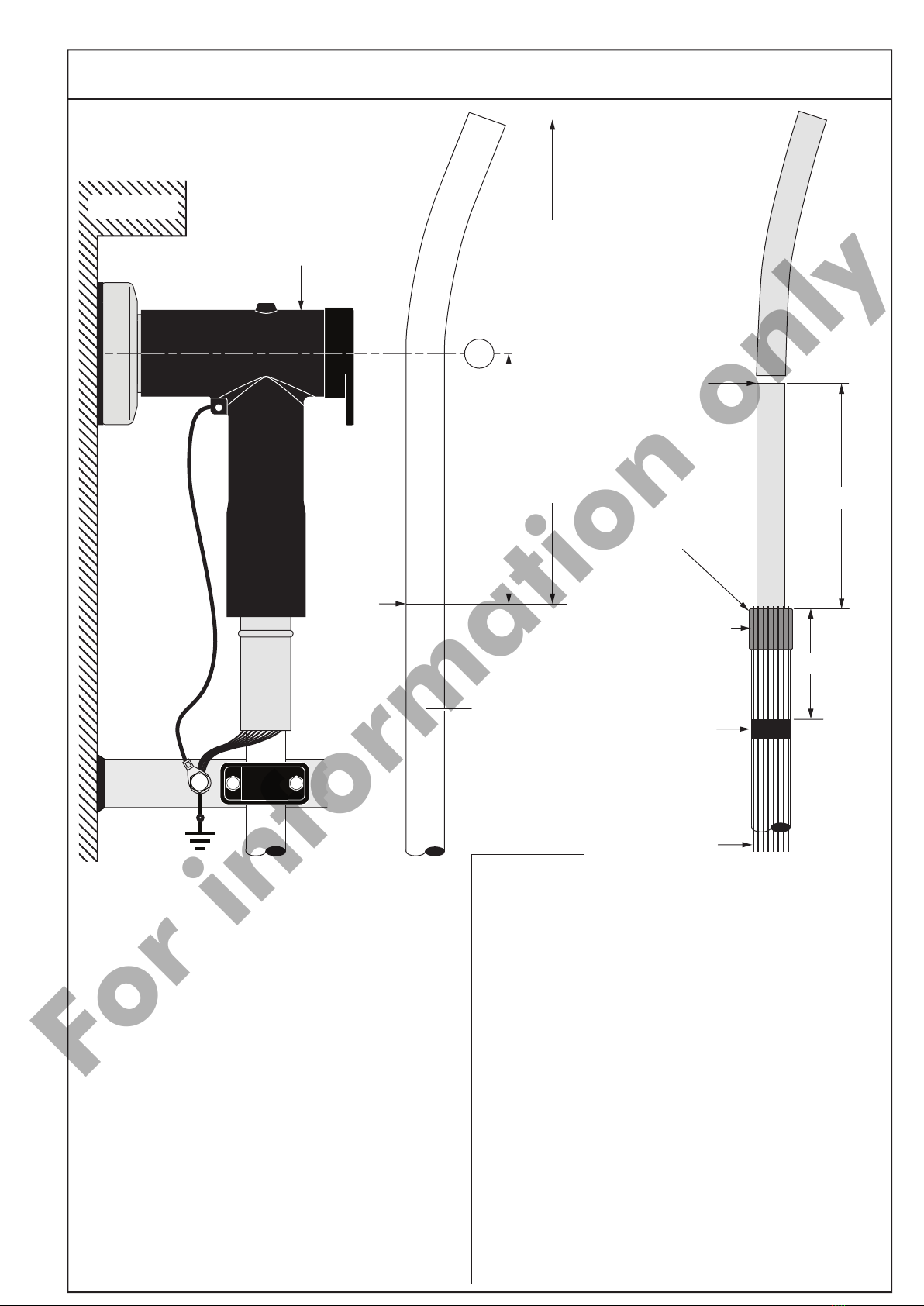

NB : Only one phase is shown in these instructions. Make off all three phases

the same way. Use a cable conversion kit for 3-core cables.

EQUIPMENT

245

necessary length of screen wire earth connection

cut back

point of

outer

sheath

outer cable

sheath

1Train the cable into the approximate finished

position next to the equipment bushing. Be sure

to allow enough extra length of screen wires

to connect to earth.

2Mark centre line « M » of the bushing.

3Remove the outer cable sheath to a point 245 mm

from the centre line « M » of the bushing.

Separable tee connector

or

first male connector

M

65

200

CUT

HERE

tape

marker

edge of the

outer sheath

copper

wires

4For indoor applications, bend the screen wires back

over the outer sheath and proceed to step no. 5.

For outdoor applications:

- Wrap one layer of water sealing mastic (type MWS)

around the outer sheath, flush with the end (25 mm

minimum width). Completely encircle the cable.

- Bend the screen wires back over the mastic and

along the outer sheath, pressing them into the

mastic.

- Important: screen wires should not touch each

other when pressed into the mastic to prevent water

ingress.

5Apply a tape marker around the outer sheath 65 mm

from the edge.

6Cut the cable to a point 200 mm from the outer

sheath.

For outdoor

applications :

one layer of water sealing

mastic (type MWS)

Page 3 of 14

IS97180-ENG - K800PB/G-CW45-CA0 - Revision 2

For information only

CABLE PREPARATION

30

semi-conductive screen

1Check distance of 200 mm.

2Remove the semi-conductive screen to a point 30 mm from the outer sheath.

For extruded easy strip semi-conductive screen:

Cut squarely taking care not to cut the core insulation.

For bonded extruded semi-conductive screen:

Use an appropriate pencilling tool. Make a clean transition between core insulation and semi-conductive screen.

200

core insulation

conductor protective

adhesive tape

2Slightly bevel the edge of the core insulation (max 2 mm).

3Thoroughly clean core insulation. Always wipe towards the screen wires.

4As a protection, wrap a few turns of adhesive tape around the conductor end.

bevel

REMOVAL OF THE CORE INSULATION

core insulation conductor

contact

conductor

1 A. Remove the core insulation from the conductor

for a distance « C » mm

(C= depth of contact bore + 10 mm).

1 B. Remove the core insulation from the conductor

for a distance « C » mm

(C= depth of contact bore + 10 mm).

A. Compression type contacts (Type TBC-X) B. Mechanical type contacts (Type TMBC-X)

10

C

core insulation conductor

contact

conductor

10

C

IS97180-ENG - K800PB/G-CW45-CA0 - Revision 2

Page 4 of 14

For information only

* USE ONLY THE SILICONE LUBRICANT SUPPLIED

1Lubricate* the indicated area: core insulation, semi-conductive screen, water sealing mastic and inner surface of the

reducer.

2Slide the reducer down the cable until flush with the tape marker.

3Remove the protective adhesive tape from the conductor.

INSTALLATION OF THE CABLE REDUCER

For conductor sizes 16 up to 150 mm²

core insulation

cable reducer

cable reducer

remove

protective

adhesive tape

lubricate

tape marker

1Slide the installation rod on to the conductor until it butts against the core insulation.

2Thoroughly clean installation rod and core insulation. Always wipe towards the screen wires.

3Lubricate* the indicated area: installation rod, core insulation, semi-conductive screen, water sealing mastic and

inner surface of the reducer.

4Slide the reducer on to the installation rod.

5Slide the reducer down the cable until flush with the tape marker. Take care to slide the reducer without hesitation

and in one smooth move.

6Remove installation rod and protective adhesive tape from the conductor.

core

insulation installation

rod

installation

rod

core insulation

lubricate

cable reducer

lubricate

tape marker

For conductor sizes 185 mm² up to 300 mm²

cable reducer remove

protective

adhesive tape

Page 5 of 14

IS97180-ENG - K800PB/G-CW45-CA0 - Revision 2

For information only

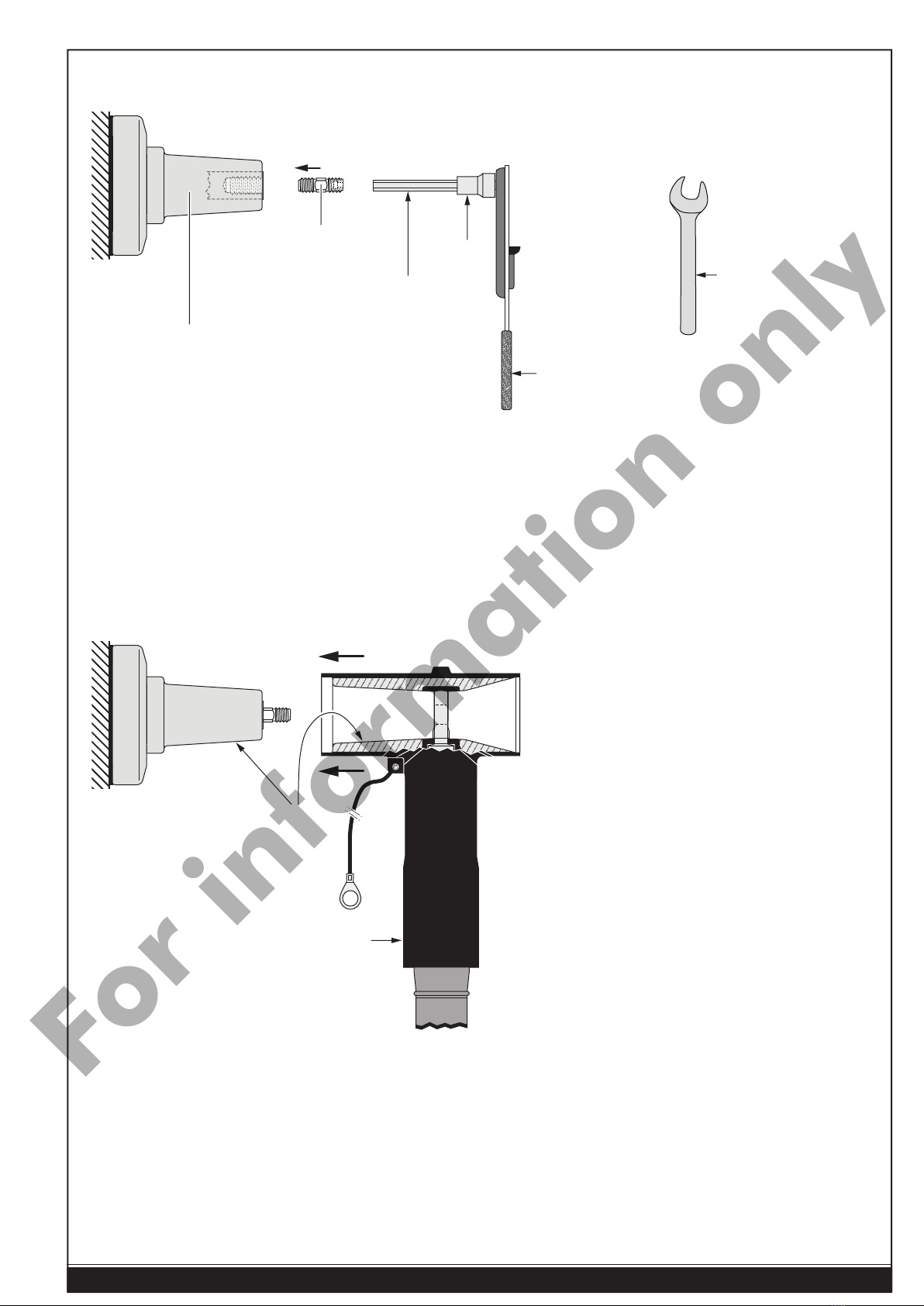

TIGHTENING OF THE CONTACT

equipment

bushing

1For aluminium conductors : before installing the conductor contact, wire brush the conductor.

2Fit the contact on to the conductor.

3Position the crimp contact taking care that the contact hole aligns with the bushing hole.

4Prior to crimping distance « Z » must be between 145 and 160 mm.

5Crimp the contact. Please refer to the crimp chart for crimp sequence.

6After crimping distance « Z » must be between 145 and 165 mm.

If necessary, adjust the position of the cable reducer until distance « Z » is within the tolerance range.

7Remove any burrs left after crimping and wipe-off excess inhibitor.

Compression type contacts (Type TBC-X)

A

Z

conductor

contact

deep indent

crimping DIN crimping

contact

palm

Please refer to the crimp chart supplied with the contact.

IS97180-ENG - K800PB/G-CW45-CA0 - Revision 2

Page 6 of 14

For information only

* USE ONLY THE SILICONE LUBRICANT SUPPLIED

COUPLING CONNECTOR INSTALLATION ON CABLE

coupling

connector

housing

lubricate

1Clean cable reducer, core insulation and contact.

2Lubricate* the inside of the connector housing and outer surface of the

cable reducer.

3Check if the outer cone interface is pointed towards the

bushing. Whilst preventing the cable reducer from

further movement down the cable gently slide the housing on the cable.

Its final position is reached when the centre

of the contact spade is along the axis of the interfaces of the connector.

4The cable reducer must stay in place during installation.

5Make sure the contact spade locks into the connector's housing.

6 Check that the ridge on the cable adapter is sitting at

5-25 mm below the connector housing.

holding tool

contact

palm

equipment

bushing

1For aluminium conductors : before installing the conductor contact, wire brush the conductor.

2Insert, if necessary, the centre ring into the contact barrel according to the table in the contact installation

instruction.

3Position the contact so that the contact hole aligns with the bushing hole.

4Tighten the contact. Please refer to the installation instruction included with the contact.

It is recommended to use a holding tool for ease of installation.

5After tightening, distance « Z » must be between 145 and 165 mm.

If necessary, adjust the position of the cable reducer until distance « Z » is within the tolerance range.

cable reducer

Before tightening

After tightening

conductor

contact

Z = 145 - 165

clean

5-25

ridge on

cable reducer

Mechanical type contacts (Type TMBC-X)

B

Page 7 of 14

IS97180-ENG - K800PB/G-CW45-CA0 - Revision 2

For information only

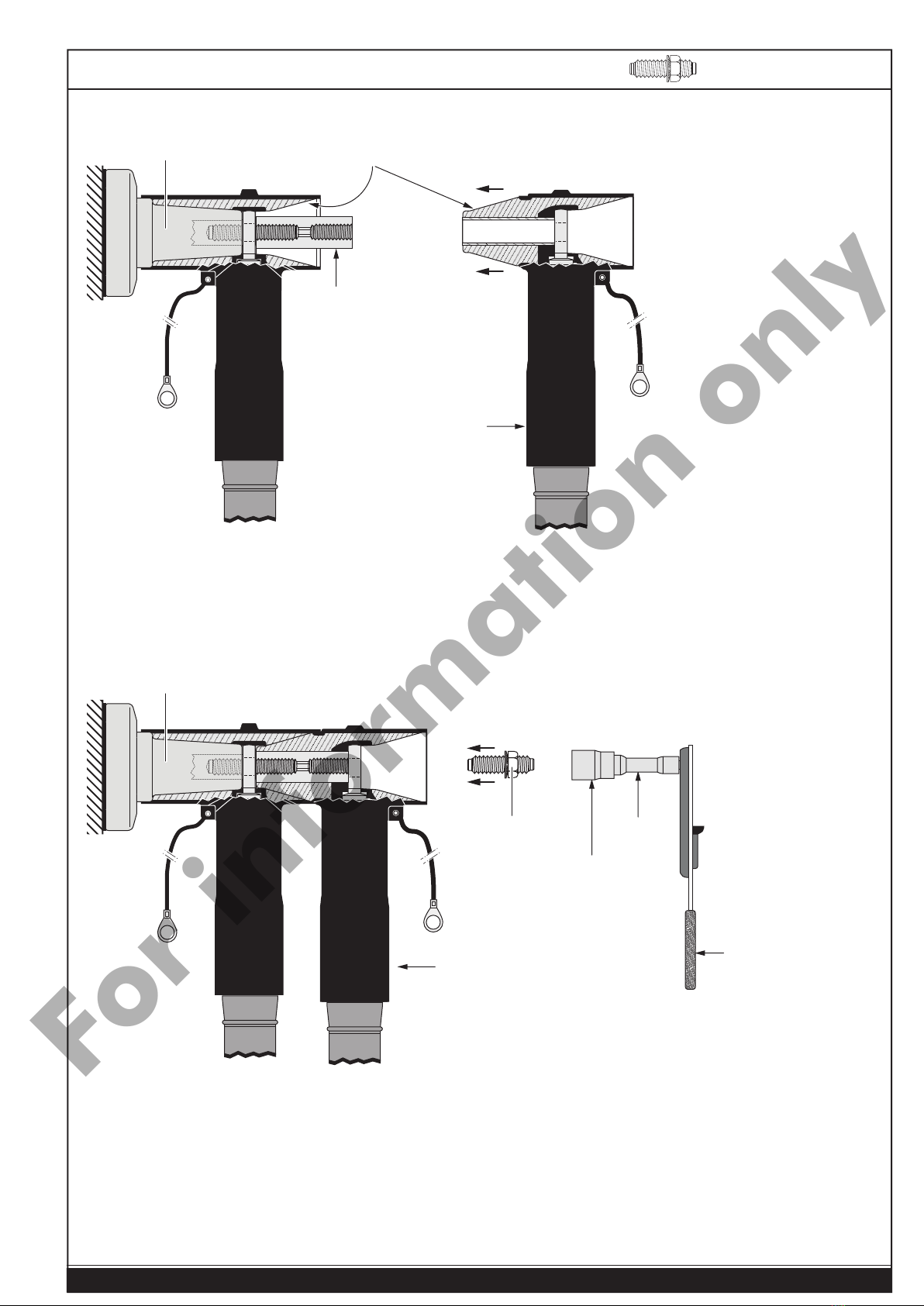

In case the tee connector has been already installed

(otherwise proceed to step no. 6).

cable

clamp

earthing

lead

copper wire

screen

clamping

screw basic

insulating

plug

Separable tee connector

protective

cap

1Remove the protective cap from the tee connector. Put the

protective cap aside in a clean and safe place for later re-use.

2Remove the basic insulating plug. Use a wrench with 22 mm

socket. Put the insulating plug aside in a clean and safe place

for later re-use.

3Type 1: remove the clamping screw. Use a wrench with a

22 mm socket and an extension. Put the clamping screw

aside in a clean and safe place for later re-use.

Type 2: remove the flange nut. Use a wrench with a 22 mm

socket and an extension. Put the flange nut aside in a clean

and safe place for later re-use.Check that M16 stud is still

mounted correctly.

Re-tighten to 30 Nm if required. Proceed with step 10

on page 10.

4Disconnect the earthing lead, copper wire screen and cable

clamps.

5Disconnect the tee connector from the bushing.

The bushing should be free.

basic

insulating

plug protective

cap

Type 1

Type 2

COUPLING CONNECTOR INSTALLATION ON TEE CONNECTOR

M16

flange nut

Page 8 of 14

IS97180-ENG - K800PB/G-CW45-CA0 - Revision 2

For information only

* USE ONLY THE SILICONE LUBRICANT SUPPLIED

8 mm

hex key

1/2" - 12,7 mm

torque wrench

8 mm

socket 13 mm

wrench

8mm

equipment

bushing

8Clean and lightly lubricate* both connector and bushing interface.

9Push the tee connector on to the bushing.

6Install M16 threaded stud into the bushing interface.

7Using a 13 mm wrench or a hex key of 8 mm, tighten the stud exerting 30 Nm (3 kgm or 22,1 foot-pounds).

connector

housing

lubricate

M16 stud

or

30 Nm

Page 9 of 14

IS97180-ENG - K800PB/G-CW45-CA0 - Revision 2

For information only

8 mm

hex key

1/2" - 12,7 mm

torque wrench

8 mm

socket

contact

rod

8mm

L≥70 mm

50 Nm

equipment

bushing

contact

rod

aInsert the contact rod on to the threaded stud.

zUse a torque wrench with a 8 mm socket and an hex key of 8 mm and tighten exerting 50 Nm (5 kgm or

36,9 foot-pounds) of torque.

In order to achieve the correct applied torque ensure that there is no lubricant on the threaded

parts.

For type 1 systems, using a clamping screw : proceed with step no 12 on page 11.

For type 2 systems, using a flange nut : proceed with step no 16 on page 12.

IS97180-ENG - K800PB/G-CW45-CA0 - Revision 2

Page 10 of 14

For information only

coupling

connector

eClean and lubricate* both female tee connector interface and male interface of the coupling connector.

rPush the coupling connector on to the contact rod of the tee connector. Take care not to damage the contact rod

during installation of the coupling connector.

22 mm

socket

1/2" - 12,7 mm

torque wrench

L ≥ 130 mm

extension

coupling

connector

22mm

* USE ONLY THE SILICONE LUBRICANT SUPPLIED

50 Nm

contact

rod

equipment

bushing lubricate

equipment

bushing

clamping

screw

tInsert the clamping screw into the threaded hole of the contact rod by hand.

yUse torque wrench with extension and a 22 mm socket and tighten exerting 50 Nm (5 kgm or 36,9 foot-pounds) of

torque.

In order to achieve the correct applied torque ensure that there is no lubricant on the threaded

parts.

Proceed with installing the basic insulation plug on page 13.

Type 1: clamping screw

Page 11 of 14

IS97180-ENG - K800PB/G-CW45-CA0 - Revision 2

For information only

coupling

connector

30 Nm

uInstall the M16 threaded stud into the contact rod.

iUsing a 13 mm wrench or a hex key of 8 mm, tighten the stud exerting 30 Nm (3 kgm or 22,1 foot-pounds).

In order to achieve the correct applied torque ensure that there is no lubricant on the threaded

parts.

oClean and lubricate* both female tee connector interface and male interface of the coupling connector.

pPush the coupling connector on to the contact rod of the tee connector. Take care not to damage the contact rod

during installation of the coupling connector.

qInstall the flange nut on to the threaded stud.

sUse torque wrench with extension and a 22 mm socket and tighten exerting 50 Nm (5 kgm or 36,9 foot-pounds)

of torque.

In order to achieve the correct applied torque ensure that there is no lubricant on the threaded

parts.

22 mm

socket

1/2" - 12,7 mm

torque wrench

L ≥ 130 mm

extension

coupling

connector

22mm

* USE ONLY THE SILICONE LUBRICANT SUPPLIED

50 Nm

contact

rod

M16

stud

equipment

bushing

equipment

bushing

Type 2: flange nut

M16

flange nut

IS97180-ENG - K800PB/G-CW45-CA0 - Revision 2

Page 12 of 14

For information only

* USE ONLY THE SILICONE LUBRICANT SUPPLIED

1Clean and lubricate* the insulating plug and the female interface of the coupling connector.

2Insert the plug into the connector and tighten assembly: use a torque wrench with a 6-point socket of 22 mm and

tighten exerting 30 Nm (3 kgm or 22,1 foot-pounds) of torque.

In order to achieve the correct applied torque ensure that there is no lubricant on the threaded

parts.

1/2" - 12,7 mm

torque wrench

22 mm

6-point socket

22mm

30 Nm

basic

insulating

plug

coupling

connector

equipment

bushing

lubricate

INSTALLATION OF THE CAP

INSTALLATION OF INSULATING PLUG

protective

cap

protective

cap

Installation on insulating plug BIPR without

voltage detection point:

- Clean the inside of the cap and the outside surface of

the connector and insulating plug.

- Place the nylon vent rod along the insulating plug

(see fig.) to exhaust the air during assembly of

the cap.

- Push the cap firmly over the connector and onto the

insulating plug.

- Press the cap on all sides to make sure it is well

positioned over the connector. Position the cap with

the pulling tab pointing downwards.

- Remove the nylon vent rod.

Installation on insulating plug BIPA with voltage

detection point:

- Clean the inside of the cap and the outside surface of

the connector and insulating plug.

- Place the nylon vent rod along the insulating plug

(see fig.) to exhaust the air during assembly of the cap.

- Push the cap firmly over the connector and onto the

insulating plug.

- Press the centre of the cap onto the locking

point until it snaps into place. Press the cap on all

sides to make sure it is well positioned over the

connector. Position the cap with the pulling tab

pointing downwards.

- Remove the nylon vent rod.

nylon vent

rod

nylon vent

rod

locking point

Page 13 of 14

IS97180-ENG - K800PB/G-CW45-CA0 - Revision 2

For information only

NOTE :

A connector/bushing mated combination should not be allowed to carry the full weight of the cable.

Therefore clamp the cable as close as possible to the connector.

IMPORTANT NOTES :

- Never disconnect connectors from energised equipment nor energise disconnected connectors without

previously installing on their appropriate corresponding mating part.

- Do not allow hydrocarbon oils or solvents to contaminate the E.P.D.M. rubber.

In the event of contamination, wipe the surface clean with a dry cloth.

system

earth

system

earth

cable

clamp

1Bend back the screen wires along the outer

sheath to form a pig tail.

2Connect the earthing lead and screen wires to

the system earth.

earthing

lead

CONNECTOR EARTHING AND CABLE CLAMPING

screen

wires

Nexans Network Solutions NV - div. EUROMOLD

Zuid III - Industrielaan 12

B-9320 EREMBODEGEM-AALST – BELGIUM

Tel: +32 (0)53/85 02 11 – Telefax: +32 (0)53/83 10 13

In case more than one coupling connector is to be installed, repeat all required steps.

or

only with

flange

nut

IS97180-ENG - K800PB/G-CW45-CA0 - Revision 2

Page 14 of 14

For information only

Table of contents

Other Nexans Cables And Connectors manuals

Nexans

Nexans N-HEAT MILLIMAT User manual

Nexans

Nexans Euromold K480TB/G User manual

Nexans

Nexans N42i.900 User manual

Nexans

Nexans ABS1335 User manual

Nexans

Nexans Euromold K489TB/G User manual

Nexans

Nexans Euromold K200LR User manual

Nexans

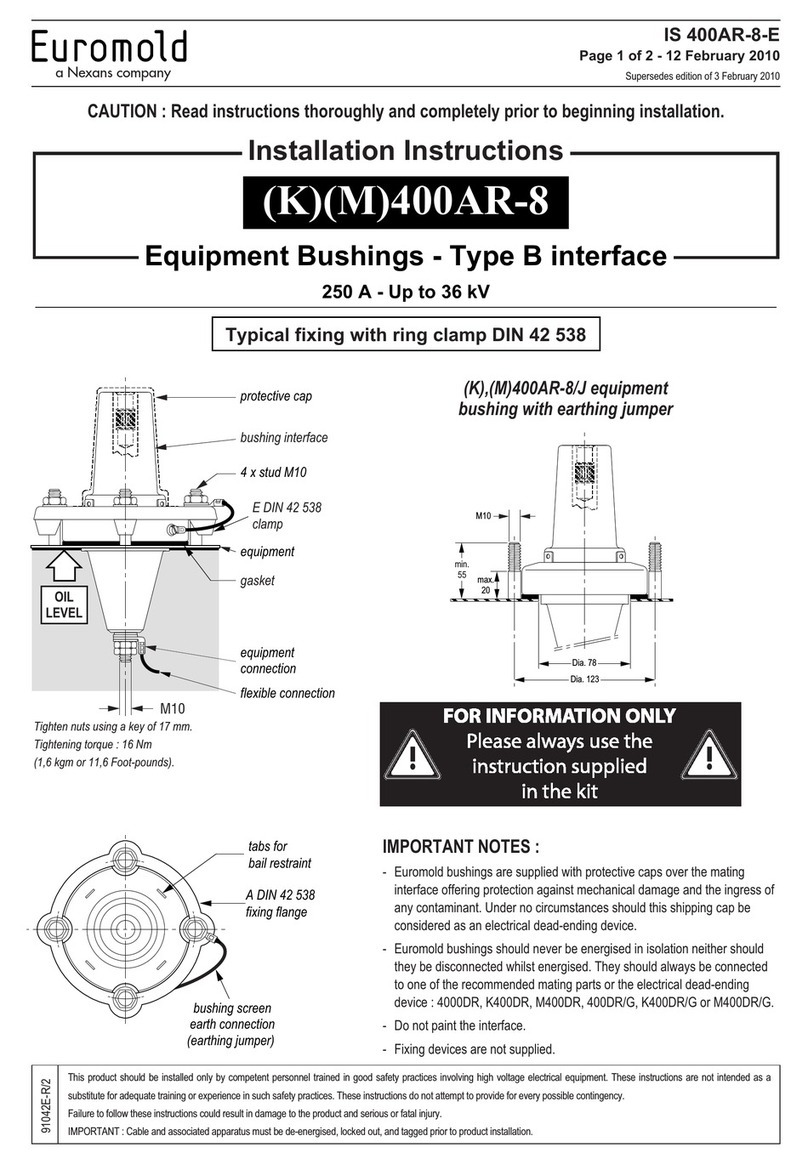

Nexans 400AR-8 User manual

Nexans

Nexans OutDrop 2+ User manual

Nexans

Nexans OUTDROP 2+ SFM Series User manual

Nexans

Nexans XPLORER Series User manual

Popular Cables And Connectors manuals by other brands

Echomaster

Echomaster P-BUA-PROMASTER CITY installation manual

Energenie

Energenie DSP-HDMI-21 user manual

PCB Piezotronics

PCB Piezotronics 010P20 Installation and operating manual

Roline

Roline 14013492 user manual

Rocket Fish

Rocket Fish RF-G1182 Quick setup guide

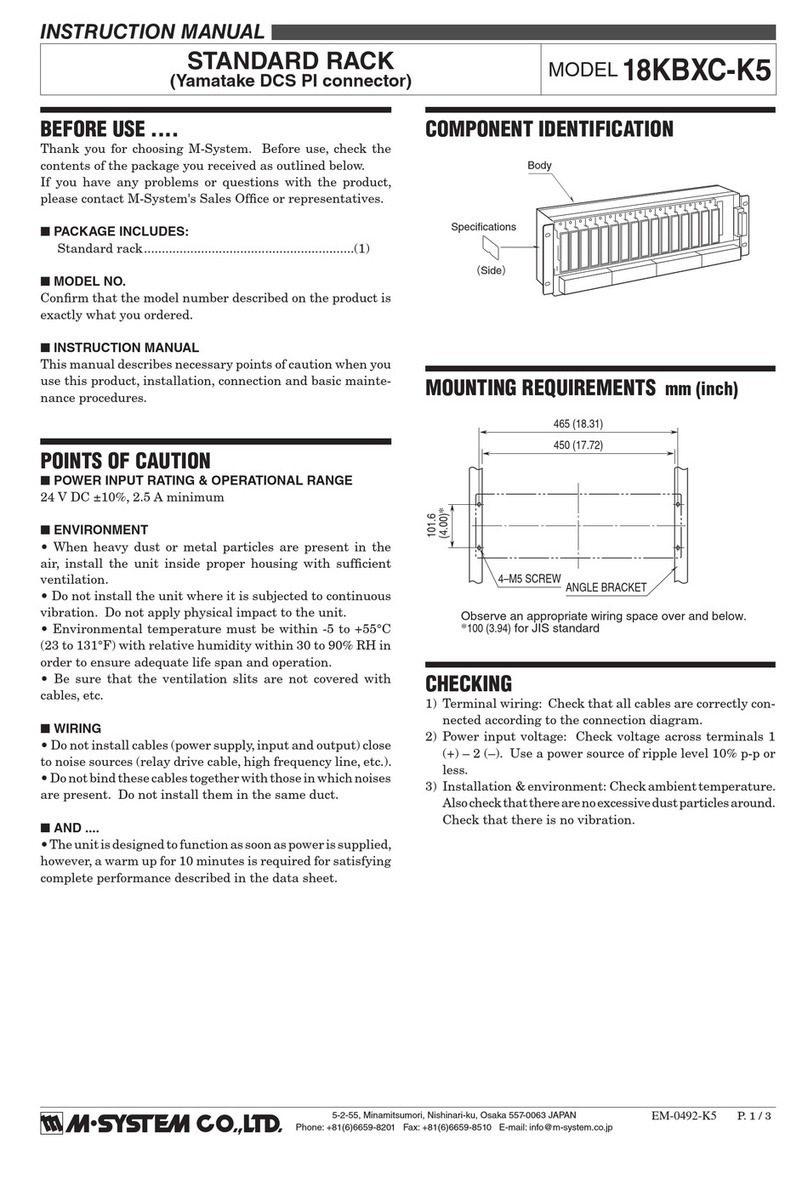

M-system

M-system 18KBXC-K5 instruction manual