7

5.0 MAINTENANCE

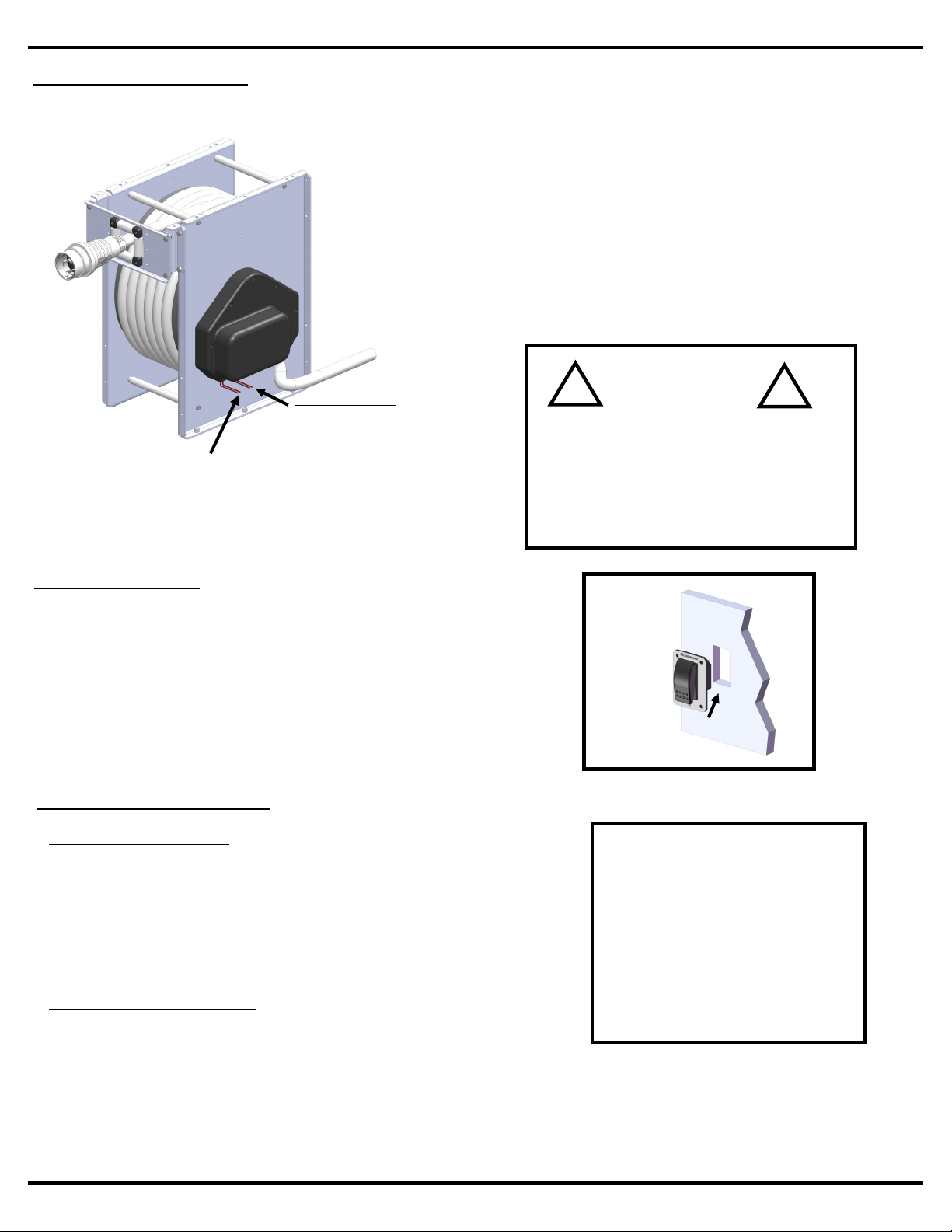

• TO RELIEVE ANY KINKING that may happen Rounely extend the power cable completely, stretch it on any at sur-

face, and allow the Cordreel to retract the cable into the reel.

• INSPECT ALL AC AND DC WIRING CONNECTIONS and make sure they are free of corrosion and connecons are

ght.

• IF THE POWER CABLE ACCIDENTALLY FALLS INTO THE WATER, do not use unl the cable has been cleaned and

dried fully. See Marine Molded Power Cord Sets 044xx User Guide for more informaon.

• INSPECT THE EXTERIOR JACKET of the power cable for nicks or cuts.

• IF YOUR POWER CABLE IS DIRTY, any cleaner should be compable with the outer jacket material of the power

cable.

• IF NEEDING TO REPLACE POWER CORDSET—Contact Glendinning Products, LLC. For replacement cordset. If using

another manufacturer’s cordset, USE ONLY 105°c MINIMUM RATED CORDSETS. Also make sure that the outside

diameter of the new cordset does not exceed that of the factory supplied cordset. Contact Glendinning Prods. For

Installaon Instrucons for replacing Cordsest

6.0 TROUBLESHOOTING

ISSUE PROBABLE CAUSE RECOMMENDED ACTION

Non-funconal (either no power

or unit has power and does not

respond)

Tripped breaker

Blown fuse at power source

Power wire incorrectly connected

to power source

Defecve motor

Reset breaker

Replace fuse

Check power source fuse and connecons,

reconnect or replace if necessary

With power switch on and voltage across motor

wires — if no response, replace motor

Cordreel stops retracng

while buon is being pushed

Cord jammed during retracon

causing breaker to trip

Reset breaker

Pay out cable and rewind

WARRANTY

PRODUCT COVERED BY THIS LIMITED WARRANTY: CRMA50/63

1. GLENDINNING PRODUCTS, LLC. warrants to the original consumer purchaser that the CRMA 50/63 will be free from defects in material and workmanship under

normal use and service for a period of one (1) year from the date of purchase.

2. This LIMITED WARRANTY applies to defects in material and workmanship. It does not apply to plated or painted nishes or to cord damage caused by inade-

quate cable storage area or installaon not in accordance with GLENDINNING PRODUCTS, LLC. specicaons.

3. This LIMITED WARRANTY is void if the product has been damaged by accident or unreasonable use, neglect, improper installaon, or other causes not arising

out of defects in material or workmanship.

4. To obtain performance of this LIMITED WARRANTY obligaon the original purchaser should contact GLENDINNING PRODUCTS, LLC. for instrucons concerning

removal and shipping of the defecve component. Upon compliance of the foregoing procedure all warranted defects will be repaired, or at GLENDINNING PROD-

UCTS, LLC. opon, the complete unit replaced and returned to the consumer, shipping charges prepaid.

5. GLENDINNING PRODUCTS, LLC. does not assume the costs of removal and/or installaon of the product or any other incidental costs which may arise as a result

of any defect in materials or workmanship.

THIS WARRANTY IS IN LIEU OF ALL OTHER EXPRESS WARRANTIES. ANY WARRANTY IMPLIED BY LAW INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS, IS

IN EFFECT ONLY FOR THE DURATION OF THE EXPRESS WARRANTIES SET FORTH IN THE FIRST PARAGRAPH ABOVE. NO REPRESENTATIVE OR PERSON IS AUTHORIZED

TO GIVE ANY OTHER WARRANTY OR TO ASSUME FOR GLENDINNING PRODUCTS, LLC. ANY OTHER LIABILITY IN CONNECTION WITH THE SALE OF IT’S PRODUCTS.

GLENDINNING PRODUCTS, LLC. WILL NOT BE LIABLE FOR ANY CONSEQUENTIAL DAMAGES RESULTING FROM THE USE OR INSTALLATION OF IT’S PRODUCTS.