Glentek Inc. 208 Standard Street, El Segundo, California 90245, U.S.A. (310) 322

TABLE OF CONTENTS

INTRODUCTION ..................................................................................................5

CHAPTER ONE: DESCRIPTION, FEATURES AND SPECIFICATIONS

1.1 Description...........................................................................................................6

1.2 Features...............................................................................................................6

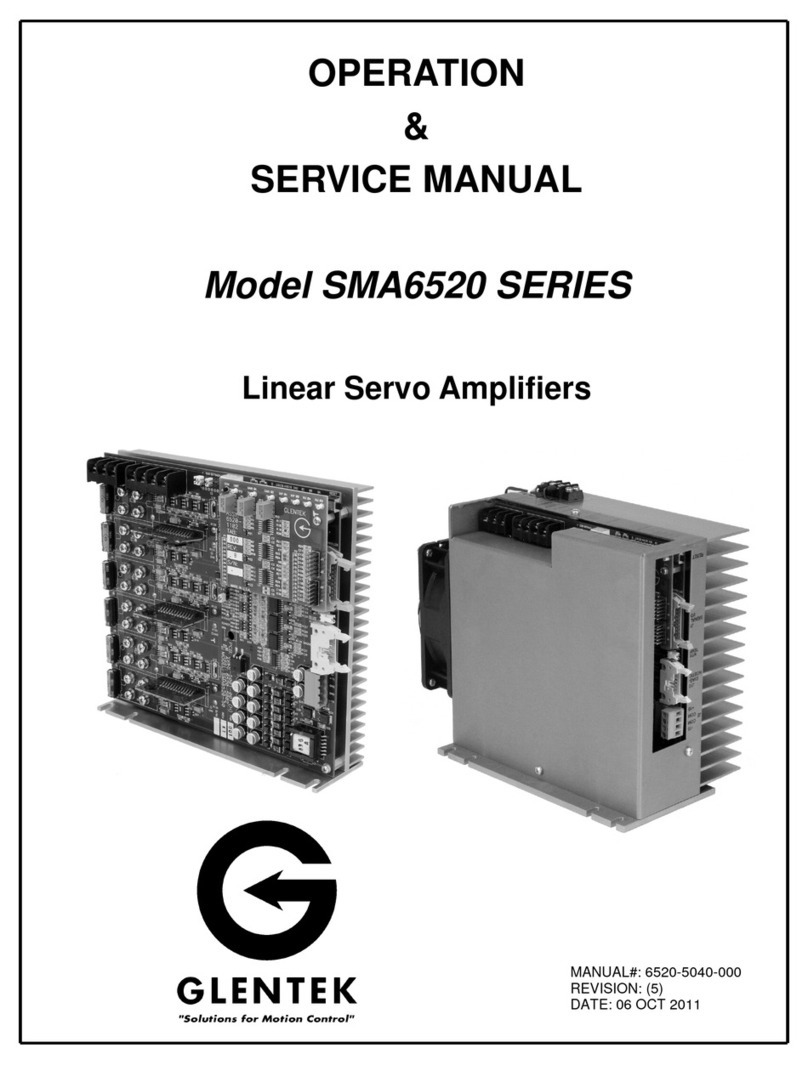

1.2.1 Single Amplifier Module (SMA7115-1)................................................................6

1.2.2 Stand Alone One Axis Amplifier (SMA7115-1A-1)...............................................6

1.2.3 Multi-Axis Power Supply (GP8600-70)................................................................7

1.3 Specifications.......................................................................................................7

1.3.1 Single Amplifier Module (SMA7115-1)................................................................7

1.3.1.1 Input and Output Power ..........................................................................8

1.3.1.2 Signal Inputs............................................................................................8

1.3.1.3 Digital Inputs............................................................................................8

1.3.1.4 System.....................................................................................................8

1.3.1.5 Outputs....................................................................................................8

1.3.2 Stand Alone One Axis Amplifier (SMA7115-1A-1)...................................................8

1.3.3 Multi-Axis Power Supply (GP8600-70) ...................................................................9

1.3.3.1 Input and Output Power................................................................................9

1.3.4 Mechanical ............................................................................................................9

CHAPTER TWO: THEORY OF OPERATION

2.1 Introduction........................................................................................................10

2.2 Driving DC Servo Motors ...................................................................................10

2.3 Servo Loops.......................................................................................................10

2.4 Brushed Motors vs Brushless Motors.................................................................11

2.5 Operation of Output Switching Transistors.........................................................12

2.6 “ H ” Type Output Bridge Configuration..............................................................12

2.7 Pulse-Width-Modulation (PWM).........................................................................13

2.8 Current-Loop Operation.....................................................................................13

2.9 Velocity-Loop Operation.....................................................................................14

2.10 Protection Circuits..............................................................................................14

CHAPTER THREE: MODEL NUMBERING

3.1 Introduction........................................................................................................15

3.2 Single Amplifier Module .....................................................................................15

3.3 Stand Alone One Axis Amplifier.........................................................................16

3.4 Multi-axis Amplifier.............................................................................................16

CHAPTER FOUR: INSTALLATION

4.1 Introduction........................................................................................................17

4.2 Mounting............................................................................................................17

4.3 Wiring ................................................................................................................17

4.3.1 RFI/EMI and Wiring Technique.........................................................................17

4.3.2 Wire Size and Type..........................................................................................17

4.3.3 Connector Size and Type.................................................................................17

4.3.3.1 The Power Connector of the Single Amplifier Module.............................17

4.3.3.2 The Signal Connector.............................................................................18

4.3.3.3 The Power & Motor Connectors of the Stand Alone Amplifier .................18

4.3.4 Amplifier Module Connections..........................................................................18

4.3.4.1 The Power Connections.........................................................................18

4.3.4.2 The Signal Connections.........................................................................19

4.3.5 Stand Alone One Axis Amplifier Connections ...................................................19

4.3.6 Multi-Axis Amplifier Connections ......................................................................19